Novel Lasers: Near-thresholdless laser works at room temperature

Every laser in practical use today has a lasing threshold, which is expressed as the applied electrical current or current density (or, if optically pumped, pump power) at which the laser's optical output changes from spontaneous emission to stimulated emission. Above the lasing threshold, the device's linewidth is much narrower (by orders of magnitude) than below threshold; similarly, the slope efficiency, which is the first derivative of the relationship of optical output to input excitation, jumps by orders of magnitude. In other words, above the threshold, the device becomes a laser.

The so-called thresholdless laser, which would lase in close-to-linear proportion to the applied pumping excitation no matter how small the excitation, has been a dream of laser scientists and engineers ever since the invention of the laser. Such a laser would, all else being equal, be more efficient, especially at low powers; it would also allow for simple incorporation of lasers into photonic circuits as devices linear throughout their range, down to zero output.

While the ideal thresholdless laser may or may not be possible, the practical definition of "thresholdless" (which, in reality, is "ultralow-threshold" or "near-thresholdless") has come to mean a laser that has a spontaneous-emission coupling factor (β) close to 1 combined with low nonradiative losses.1 Such lasers have been created that operate at cryogenic temperatures of around 4 K, consisting of small numbers of quantum dots (QDs) in an optical cavity.2 Clearly, though, the required low temperatures preclude use of such lasers in photonics circuits, which must ideally be able to operate not just at room temperature but at elevated temperatures.

Now, a group of Spanish and Swiss researchers has created a thresholdless laser that operates at room temperature and above; the laser is based on indium arsenide antimonide (InAsSb) QDs that are placed in a photonic-crystal microcavity (PCM) and emit at a 1286 nm wavelength at room temperature.3 The researchers themselves hail from the Instituto de Microelectrónica de Madrid (IMM; Spain); the Laboratory for Solid State Physics, ETH Zurich (ETHZ; Switzerland); the Optoelectronic Materials & Devices Unit (UMDO), Universitat de València (Spain); and the Optics and Quantum Communications Group, Instituto de Telecomunicaciones y Aplicaciones Multimedia (ITEAM; Valencia, Spain).

Photonic-crystal-defined cavity

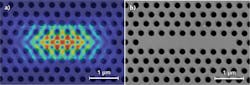

The PCM, which is fabricated on a suspended slab of gallium arsenide (GaAs), consists of a hexagonal 2D photonic crystal with a linear section having nine missing holes, forming the optical cavity (see Fig. 1). The PCM was optimized to spectrally match the fundamental mode of the QD emission.

To create the PCM, epitaxial material was first grown on a GaAs substrate, including an aluminum gallium arsenide (AlGaAs) sacrificial layer and a 190-nm-thick layer of GaAs containing the InAsSb QDs. After patterning the active layer and transferring the pattern to the GaAs slab, the sacrificial layer was removed, leaving the suspended slab.

The thresholdless laser itself was pumped with light from a continuous-wave (CW) laser diode emitting at a 785 nm wavelength, focused to a 1.5 μm spot with a microscope objective, which also served as a PCM to collect the light emitted by the laser under test; the light was focused into an optical fiber and fed to a spectrometer with a cooled InGaAs photodiode array as a detector.

The researchers chose to add Sb to InAs QDs to improve performance at room temperature. The improved performance at high temperatures occurs because the Sb shifts the conduction and valence band edges upward, which produces a deeper hole confinement; this reduces the thermal escape of carriers and results in more efficient emission at room temperature.

The researchers note that "the study of the emission of the devices as a function of the temperature is not straightforward due to the thermal drift of the QD emission, which is much larger than that of the cavity mode. Therefore, the cavity mode will be highly detuned as the temperature is changed." As a result, they say that the only way to do a thorough study over a range of temperatures would be to make a different PCM for each temperature. Even then, such a study would not be conclusive due to the individual differences between the cavities. So the researchers decided to study most thoroughly room-temperature operation at a 1286 nm wavelength, for which the fabricated PCM resonance was designed.

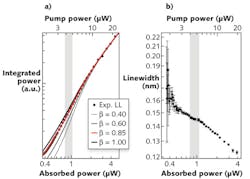

Values for the integrated intensity of light emitted in the fundamental mode by the PCM laser were experimentally obtained as a function of pump power—otherwise called a light—in versus light-out curve (see Fig. 2a). Such a curve helps determine the behavior of the laser in the region where it begins to lase.Curves depicting various values of the spontaneous-emission coupling factor β were calculated; a value for β of 0.85 best fit the experimental data. This value is about the same as the β reported for the earlier-mentioned cryogenic thresholdless lasers.

Ultralow 860 nW threshold

To help determine the point at which the device began lasing, linewidth of the resonant mode was measured as a function of input optical power (see Fig. 2b). Regions of mostly spontaneous emission, amplified spontaneous emission (ASE), and stimulated emission were determined. The laser's threshold was ascertained to be 860 nW of input power, low enough for the laser to earn its "thresholdless" designation.

The cavity quality factor Q of the device, determined by the ratio of the emitter's wavelength divided by its linewidth, was 7400 at its lowest excitation power of 370 nW and 12,100 at an excitation power of 10.14 μW. The researchers say that another confirmation of lasing could be provided by doing an analysis of the second-order correlation function (g2), which helps determine the statistics of the device's intensity fluctuations and thus its manner of operation.

"The next step is to keep going in the characterization of the devices, especially the measurement of the correlation function, and the application of the devices to near-zero-power-consuming optical sensors," says Pablo Aitor Postigo, one of the IMM researchers.

The PCM laser results show that thermally driven processes such as nonradiative recombination do not prevent the development of thresholdless lasers at room temperature and above. If electrically injected versions of these devices can be developed and made practical, very efficient photonic circuits could be just one of the potential results.

References

1. S. Noda, Science 314, 260–261 (2006).

2. S. Strauf et al., Phys. Rev. Lett. 96, 127404 (2006).

3. I. Prieto et al., Optica 2 (1), 2334 (2015); http://dx.doi.org/10.1364/OPTICA.2.000066.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.