Researchers at the University of California, Santa Barbara (UCSB) and Mitsubishi Chemical Corporation (Ibaraki, Japan) have developed a backside-roughening technique for blue semipolar gallium-nitride (GaN)-based LEDs that makes them comparable to commercial wurtzite c-plane LEDs in terms of both performance and manufacturing methods.

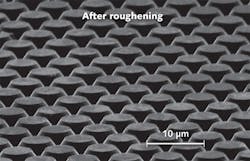

Semipolar and nonpolar GaN LEDs, while theoretically having higher optical gain than c-plane devices, have poor light-extraction efficiency caused by the low critical angle of the light escape cone (23°) due to the high refractive-index (n) difference between GaN (n = 2.5) and air (n = 1) and the fact that surface-roughening techniques have not been deployed as they have for c-plane devices. Using an etching technique, the research team fabricated conical features with varying diameters and with different densities on the backside of GaN LEDs. Using both simulated and actual experiments, a 4 μm diameter conical pattern with a density of (2 × 106)/cm2 yielded an optimum output of 31.1 mW with an external quantum efficiency of 54.7%—comparable to the best commercial c-plane blue LED devices. Contact Yuji Zhao at [email protected].