SHORT-WAVELENGTH LASER DIODES: Green diodes create new growth opportunities in photonics

PAUL RUDY

Recent progress in the commercialization of green- and blue-emitting laser diodes is creating opportunities to expand existing markets as well as enabling new growth segments. The advantages inherent in visible "direct diode" lasers are expected to drive market growth from displacement of other visible lasers in elastic applications segments within defense, industry, and medicine. Moreover, new applications in display and illumination will be created by converting users of nonlaser sources, such as specialty lamps and light-emitting diodes (LEDs), to laser diodes.

Visible laser applications were originally served by helium-neon and argon-ion gas lasers until the subsequent introduction of lamp-pumped solid-state lasers, diode-pumped solid-state lasers, infrared semiconductor lasers, and second harmonic generation (SHG) techniques. While these SHG laser systems are adequate for specialty blue and green laser applications today, they are still too inefficient, bulky, expensive, temperature sensitive, and fragile for broad deployment into high-volume applications. Whenever possible, red laser diodes are used because they are smaller and less expensive—but for many applications, red is not an optimal wavelength choice, and blue or green is required.

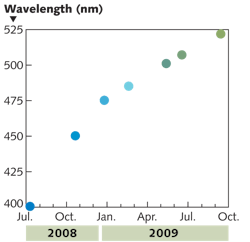

In 1995, Shuji Nakamura et al. demonstrated the first indium gallium nitride (InGaN)-based visible laser diode, which was fabricated on sapphire and operated in the violet region.1 This demonstration marked the birth of a new class of "direct diode" visible lasers that offers reduced cost, a compact form factor, increased durability, reduced temperature sensitivity, increased design flexibility, and the potential for high efficiency. Since this first demonstration, InGaN-based lasers have rapidly improved in efficiency and lifetime across both the violet and blue regions. They are used in reprographics and have enabled applications such as the Blu-ray Disc. More recently, the development of innovative InGaN laser diodes on nonpolar and semipolar GaN substrates has enabled higher-efficiency blue-emitting laser diodes and the extension of continuous-wave lasing wavelengths into the green region of 520–525 nm (see Fig. 1).2

These direct-emitting blue and green lasers offer enormous benefits compared to conventional SHG blue and green lasers—see "Benefits of green laser diodes." As direct-emitting green and blue laser diodes become widely available, we expect their advantages to transform the visible laser industry by expanding existing applications and enabling new ones.

Defense and security

On the battlefield and in secure environments, blue and green visible lasers are used in a range of applications. These include pointing, warning, threat detection, undersea communications, and head-up and projection displays. Increasingly, defense and security applications are migrating away from large centralized specialty installations toward decentralized man-portable units on the ground, unmanned aerial vehicles (UAVs) in the air, and ultracompact marine vehicles. Green and blue laser diodes are critically important for security personnel and the warfighter in this context because of their advantages, mentioned earlier, as compared to SHG lasers.

In one example, green laser diodes are an ideal solution for broad deployment of nonlethal threat detection lasers (threat assessment, threat de-escalation, visual warning technology, and laser dazzling, also called "hail and warning"). End users of these tools include soldiers on the battlefield, homeland security officers, police, and general security in any potentially hostile situation. The threat detection measure provides an opportunity for de-escalation while at the same time providing a strong visual warning that can "dazzle" or induce temporary blindness to disorient approaching hostile parties without causing permanent ocular damage.

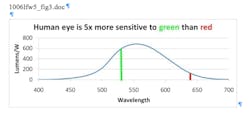

Wide deployment of lasers in this context requires that the devices meet demanding portability and ruggedness requirements. Dazzlers must emit green light since the eye is most sensitive to green wavelengths. Red laser diodes are not practical in this application since, for the same amount of optical power, the human eye is typically more than five times more sensitive to green light (see Fig. 2). Three-stage diode-pumped solid-state (DPSS) lasers are in use for this application but have critical limitations originating from relative inefficiency, fragility, and sensitivity to alignment temperature, as well as fixed wavelength at 532 nm. As noted previously, an InGaN laser diode that directly produces a green laser beam from a single-stage tiny laser chip can eliminate the drawbacks to existing DPSS systems.These advantages of a direct diode solution remove the barriers to broad deployment and allow the majority of soldiers, UAVs, and miniature marine vehicles to be outfitted with laser solutions.

Biomedical

Similar to the defense market, medical and industrial laser applications that today utilize multistage blue and green SHG lasers are expected to migrate to direct diode solutions and grow in volume as a result. Bioinstrumentation and medical therapeutic applications based on blue and green lasers are currently quite successful in the laboratory, but a broad proliferation of portable analysis devices has not occurred because of the disadvantages inherent to current SHG solid-state laser systems. Additionally, the existing laser solutions lack cost-effective wavelength design flexibility. A direct diode approach makes it possible to achieve the required compact size and ruggedness, along with different emission wavelengths, such as 515, 507, or 488 nm.

Displays

The emergence of commercially available laser projectors in 2009 increased the popularity of laser-based displays. They are expected to gain further traction in the coming years. Miniature projectors project large images (in excess of 60 in.) from a handheld device for viewing movies, Internet surfing, and video conferencing. To unlock the potential of the laser display market, the lumen output of the projector must be maximized while minimizing power consumption, size, and cost.

Typical laser projectors consist of a light source (laser, LED, or lamp), optics, display generating technology (such as a liquid crystal or a micro-mirror device), electronics, and power source. Nonlaser light sources such as LEDs and lamps suffer drawbacks that include being unpolarized (leading to excessive optical losses); poor spatial mode quality, which necessitates large LCOS or LCD chips; and being incompatible with compact scanning mirror designs because the light cannot be focused into a small area. It is possible to use multistage SHG lasers for laser projectors, but these systems are then expensive, bulky, difficult to modulate at high speeds, and emit a narrow spectrum, causing speckle in the image.

Blue and green direct-emitting laser diodes are ideal since they offer highly polarized output and single spatial mode compatible with scanning mirror designs. Additionally, they output a substantially wider spectral width to reduce speckle, with high efficiency, and offer high-speed modulation compatible with scanning mirror, LCOS, or MEMS array display technologies.

Coming soon: 3D

Advances in 3D entertainment are driving a significant upturn in its popularity. As a result, 3D content is being generated aggressively by major film studios, video game makers, and the sporting event community. As the means for transporting and generating 3D content is being standardized, 3D displays are also being developed and manufactured and some will be available soon for handheld devices, as well as televisions and home theater. Direct-emitting blue and green laser diodes are critically important for next-generation pico-projectors that produce big-screen images in 3D on any surface from a miniature handheld device.

While several techniques for displaying and viewing 3D content exist, 3D viewing is generally achieved by broadcasting one image to the right eye and another separate image to the left eye. When one is not in control of the screen, as in the case of miniature portable pico-projectors, it is most convenient to display two images with different colors and wear passive glasses with spectral filters to separate them. The glasses are inexpensive, and the approach is excellent for any viewing surface. To achieve this type of 3D display spectrally requires two red-emitting sources, two green, and two blue. The sources of the same color are slightly detuned from one another so that notch filters can selectively filter out one of the sources from the observer's view. The approach is independent of microdisplay technology and is compatible with LCOS, MEMS array, and scanning micro-mirrors. The approach is a natural extension of the 2D laser projectors being commercialized now.

REFERENCES

- S.Nakamura, M. Senoh, S. Nagahama, N. Iwasa, T. Yamada, T. Matsushita, H. Kiyoku, and Y. Sugimoto, "InGaN Based Multi-Quantum-Well-Structure Laser Diodes," Jpn. J. Appl. Phys. 35, 74–76 (1996).

- J. Raring, E. Hall, M. Schmidt, C. Poblenz, B. Li, N. Pfister, D. Feezell, R. Craig, J. Speck, S. DenBaars, S. Nakamura, "High-power high-efficiency continuous-wave InGaN laser diodes in the violet, blue, and green wavelength regimes," SPIE Defense and Security Symposium, Paper Number 7686-18 (2010).

Paul Rudy is vice president of business development at Kaai Inc., Goleta, CA; e-mail [email protected]; www.kaai.com.

Benefits of green laser diodes

The green-emitting laser diode offers a number of compelling advantages compared to an equivalent green-output second harmonic generation (SHG) device. These include:

Efficiency: A laser diode is a single-stage device so it is inherently more efficient than a multistage device. Hence, fewer batteries (less power) are needed and the efficient generation of light minimizes waste heat (which otherwise must be managed and carried away). Overall, up to a 10× reduction in size and weight is possible (compared to SHG devices) as well as reduced costs.

Ruggedness: The green laser light is generated within the chip, so no external optical alignment is needed to maintain lasing. This dramatically reduces manufacturing costs as well as eliminating a subsequent field failure mechanism.

Operating temperature range: The laser diode is insensitive to minor changes in temperature and can operate over a 5× larger range (compared to SHG devices) without a temperature control mechanism or active heating/cooling. This greatly reduces the system complexity, cost, size, and weight, and eliminates failure mechanisms.

Operating characteristics: The laser diode operates with up to a 10× increase in linewidth—which brings a dramatic reduction of speckle—and a more than 1000× increase in modulation speed, thus enabling direct modulation of the device. Furthermore, different emission wavelengths are possible such as 515, 507, or 488 nm.

Safety: The laser diode produces only green light. Unlike SHG devices it does not produce any (fundamental) 1064 nm light. This eliminates the need for a blocking filter, which reduces cost and complexity. Because there is no residual 1064 nm emission, any risk of exposure to an infrared beam is eliminated.