LIGHT-EMITTING DIODES: Nanorod arrays enable natural-white LEDs

Indium gallium nitride (InGaN)-based LEDs are currently available only with emission in the blue and green region as a result of the strong quantum-confined Stark effect (QCSE) in lattice-mismatched polar InGaN quantum wells. Although white-light LEDs can be fabricated using yellow phosphors on InGaN structures, efficiency is relatively low and color rendering is poor.

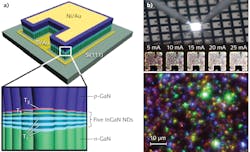

Recognizing that the wavelength-dependent QCSE limits emission efficiency primarily due to the lattice mismatch between indium nitride (InN) and gallium nitride (GaN) as well as the polar nature of the crystalline structure, researchers at National Tsing-Hua University (Hsinchu, Taiwan) developed a new recipe for a phosphor-free white LED that uses GaN nanorod arrays on silicon (Si) substrates as a template for growing strain-free InGaN/GaN nanorod heterostructures that eliminate piezoelectric polarization effects.1

Growing strain-free nanodisks

Using plasma-assisted molecular-beam epitaxy, vertically self-aligned GaN nanorod arrays were grown along the wurtzite c-axis of 3 in. n-type Si substrates.2 These arrays exhibit the properties of strain- and dislocation-free single crystals and can then serve as nanostructured compliant templates for growing strain-free InGaN nanodisks on top of GaN nanorods. By controlling the InxGa1-xN composition, nanodisk emitter ensembles with emission ranging from blue to red across the visible spectrum can be grown. To create a white-light LED, a stack of nanodisk emitter ensembles is then embedded in the GaN p-n junction to obtain the desired light-mixing effects.

Even though other research groups have fabricated white-light LEDs in multiple-quantum-well planar InGaN/GaN and other modified structures, the InGaN active structures, limited by the QCSE effect, are typically quite thin (only 2 to 4 nm thick), resulting in less than optimal white-light output. Because the nanorod structures are typically 10 to 25 nm thick, these large and tunable active-region volumes improve carrier capture with reduced electron overflow at high currents, enabling color mixing that produces a superior natural-white output with a color temperature of approximately 6000 K.

Insensitive to drive current

Analysis of the ensemble electroluminescent emission from five stacked nanodisks within the white-light LED structure shows two major ensemble peaks in the blue and yellow spectral regions. Both of these blue- and yellow-band intensities increase monotonically with increasing injection current at a constant slope, producing a drive-current-insensitive white-light hue.

Because special nanofabrication techniques are not required to grow these LED structures, and because manufacture is easily scaled through the use of silicon substrates, potential fabrication costs are low.

"The significance of InGaN nanodisk-based strain-free LEDs is the possibility to overcome the QCSE limitation and extend the operational range of monolithic InGaN LEDs into full-color and white, which would be great news for lighting and display applications," says Shangjr (Felix) Gwo, professor of physics and dean of research and development at Tsing-Hua University. "Additionally, the nanodisk/nanorod geometry allows for the realization of the smallest footprint LEDs to be used as subwavelength light sources."

REFERENCES

1. H.-W. Lin et al., Appl. Phys. Lett., 97, 073101 (Aug. 16, 2010).

2. H.-Y. Chen et al., Appl. Phys. Lett., 89, 243105 (2006).

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.