QUANTUM CASCADE LASERS: Advances push QC lasers into the mainstream

ARKADIY LYAKH, RICHARD MAULINI, ALEXEI TSEKOUN, and C. KUMAR N. PATEL

Quantum cascade lasers (QCLs) are a novel class of semiconductor devices that fill the critically important mid-wave infrared (MWIR) and long-wave infrared (LWIR) spectral gaps. But for much of the time since they were first demonstrated in the mid-90s, QCLs remained little more than laboratory curiosities because they lacked the required performance and reliable packaging for easy system integration, and early devices operated only at cryogenic temperatures.1 In fact, continuous-wave room-temperature (CW/RT) performance was not achieved until 2002.2

In terms of usability, QCLs were initially sold as individual chips or as unpackaged chip-on-carrier assemblies, thereby relegating them to the status of laboratory devices. The acceptance barrier to insertion in real applications remained formidable, requiring a potential system integrator to become an expert in the specifics of QCL handling, packaging, and powering.

We have addressed these performance and usability challenges to move QCLs into the application mainstream. By applying the telecom-laser paradigm of standard high-level performance and well-defined mechanical, optical, and electrical interfaces to our QCL program, we have developed high-performance QCLs packaged in easy-to-use, self-contained modules. These devices have resulted in greatly increased acceptance of QCLs by systems integrators.

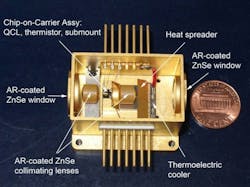

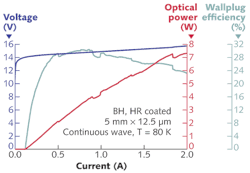

In terms of device performance, we recently demonstrated a record-high usable CW/RT output power of 3 W from a single facet and a wall-plug efficiency of 13% at 4.6 µm. This achievement required multiple advances spanning the entire QCL fabrication chain, from fundamental design of the active region through ex-chip thermal management. To simplify system integration of these lasers, we package them in hermetic, self-contained packages that require only electrical power and heat sinking to operate. To reduce the overall integration risks, we have designed laser controllers for bench-top as well as OEM applications of QCLs. As a result, QCLs are gaining acceptance in real-world applications, including systems to protect military and civilian aircraft and high-power handheld target illuminators. In addition, other areas for QCL insertion, such as free-space optical communications, ultrasensitive trace-gas sensing and remote sensing, are emerging.

Active-region design

Quantum cascade lasers are unipolar semiconductor devices based on intersubband transitions in a heterostructure, in which the parameters influencing laser operation, including lifetimes of the relevant electronic states and dipole matrix elements between them, are not intrinsic properties of the material, but depend on the thickness and depth of the quantum wells and barriers in the active-region design.

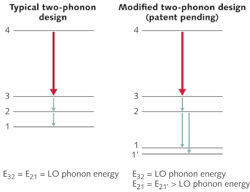

Most of today's QCL structures use the two-phonon resonance approach where the radiative transition from the upper laser level 4 to the lower laser level 3 is followed by two consecutive nonradiative transitions to the levels 2 and 1 (see Fig. 1).3 The energy spacings E32 and E21 are designed to be roughly equal to the longitudinal optical (LO) phonon energy, ELO, in the material (about 35 meV in indium gallium arsenide), leading to short lifetimes for electrons in levels 3 and 2 and rapid depopulation of the lower laser level. However, once the restrictive two-phonon condition is met, not much flexibility remains for changing other parameters of the design because active-region layer thicknesses are essentially fixed by the resonance condition and the desired laser transition energy.

To regain design flexibility, the two-phonon resonance condition must be removed without sacrificing the efficient carrier extraction from the lower laser level.4 We have achieved this goal by providing several (in this case, two) parallel extraction paths from level 2. While the individual transitions 2-1 and 2-1' are less efficient than in the resonant case, the summation over multiple possible transition paths results in lower-state lifetimes comparable to those achieved in two-phonon design. This approach, named nonresonant extraction, has become a very attractive and flexible tool for QCL design.

Fabrication and packaging

Quantum cascade lasers containing, typically, 500 to 1000 roughly nanometer-thick layers are very demanding structures for epitaxial growth. For MWIR QCLs, the difficulty is enhanced because the layers must be strained to provide sufficient conduction-band discontinuity to confine carriers, and the strain needs to be balanced throughout the superlattice to avoid the formation of dislocations. We continue to optimize the epitaxial growth to achieve ever-improving overall performance of the devices.

Thermal management in QCLs requires a special mention. The "waste" heat produced in the QCL during greater than 2 W CW/RT operation is about 50 kW/cm2. Using buried-heterostructure processing of the QCLs and bonding them epi-side down for efficient heat removal has enabled us to demonstrate a CW power of 2.9 W at 293 K for QCLs mounted on aluminum nitride (AlN) submounts.5, 6 Our use of industrial-grade hard solder, CTE-matched process, is in contrast to many published high-power QCL data that describe lasers mounted on diamond substrates with indium—an approach that is incompatible with long-term device reliability. We have also demonstrated high-power operation of QCLs without thermoelectric cooling (often called "uncooled" operation) with an average power (pulsed) of 1.2 W and CW power over 1 W.6 Recently, improved thermal management has yielded uncooled operation average power output of 1.5 W.

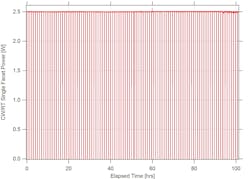

It is critical to note that the output power and wall-plug-efficiency numbers cited above are for single-ended emission. As with all edge-emitting semiconductor lasers, as-cleaved QCLs emit light equally from both facets. In many publications, the output of the two facets is summed to arrive at the cited output-power numbers. While a valid scientific result, such a device is hardly suitable for practical applications requiring single-ended output, which for semiconductor lasers is achieved by depositing a high-reflection (HR) coating on one of the facets. For high-power QCLs this is a demanding task because the optical power density on the facet of a typical 2 W QCL can exceed 10 MW/cm2. Our developments have yielded HR coatings resistant to catastrophic optical damage and that ensure excellent long-term device reliability. We have accumulated many thousands of hours of degradation-free operation for CW/RT devices over 1 W (see Fig. 2).System integration

Powering QCL devices is more difficult than near-IR semiconductor lasers because these lasers typically require significantly higher drive voltages (12 to 16 V) than diode lasers. Furthermore, as a result of their still low (compared to diode lasers) wall-plug efficiency, QCLs require advanced thermal-management solutions. A state-of-the-art QCL operating at 2 W with more than 10% wall-plug efficiency generates 18 W of waste heat that is removed using a TEC (which itself generates more waste heat), making system-level thermal management critical.To provide engineers with a means to study the suitability of QCLs for their application, we have developed a demonstrator system, which is also independently valuable as a lab instrument (see Fig. 5). The system operates off standard AC electrical supply, is air-cooled, and provides CW/RT power in excess of 2.5 W.

REFERENCES

- J. Faist et al., Science 264, p. 553 (1994).

- M. Beck et al., Science 295, p. 301 (2002).

- J. Faist et al., IEEE J. Quant. Electron. 38, p. 533 (2002).

- A. Lyakh et al., Appl. Phys. Lett. 95, p. 141113, (2009).

- A. Tsekoun et al., PNAS 103(13), p. 4831 (2006).

- R. Maulini et al., Appl. Phys. Lett. 95, p. 151112 (2009).

- www.pranalytica.com

Arkadiy Lyakh, Richard Maulini, and Alexei Tsekoun are senior scientists and C. Kumar N. Patel is chairman and CEO of Pranalytica, 1101 Colorado Ave., Santa Monica, CA 90401; e-mail [email protected]; www.pranalytica.com.