Femtosecond lasers are excellent tools for microstructuring of solid materials (see Laser Focus World, May 2002, p. 77). At relatively low laser fluences, close to the ablation threshold, these lasers allow high-quality material processing and large-area patterning of solids without any visible thermal or mechanical damage.

For applications requiring high processing speed, however, the laser fluences are well above the ablation threshold. At these laser fluences the energy coupled into a workpiece and the corresponding thermal load are high, comparable to that with nanosecond and longer laser pulses. Therefore, in the high fluence regime, one usually does not expect any considerable advantages for materials processing with femtosecond lasers. We demonstrate that, even at high laser fluences, much better results can be obtained with femtosecond lasers.

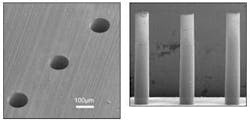

For deep drilling of metals, the most important criteria are the hole geometry and its quality. Femtosecond lasers allow deep, high-quality holes to be drilled without the post-processing usually required with other laser systems. High-intensity femtosecond-laser pulses rapidly drill a through-hole. The high intensity part of the laser pulse propagates directly through the hole without absorption. Only at the edge of the laser pulse, at laser intensities close to the ablation threshold, a small amount of material is removed.

Starting from this, the interaction of femtosecond laser pulses with the workpiece occurs in the low-fluence regime, where all advantages of femtosecond lasers can be realized. The result is an "integrated" low-fluence femtosecond laser post-processing (or a low-fluence finishing), which is responsible for the excellent hole quality.

Günter Kamlage, Andreas Ostendorf, and Boris N. Chichkov

Laser Zentrum Hannover e.V.

Hollerithallee 8, D-30419

Hannover, Germany

email:[email protected]