Underwater topography demands high-reliability laser

Laser systems are often designed to emphasize performance features such as efficiency or power, but a system designed by engineers at Cutting Edge Optronics (St. Charles, MO) for use in underwater topography tasks such as minesweeping had of necessity to focus on ruggedness and reliability.

For instance, the diode array is run very conservatively in the 532-nm diode-pumped solid-state laser (DPSSL) system that Mark Kushina described on behalf of his research team at Photonics West in January, so that the wall-plug efficiency varies from 0.7% at the low end of the operational temperature range to 1.25% at the high end. But then again the system operates reliably in water temperatures ranging from 0°C to 35° C.

The laser is controlled remotely through a cable from the ship or helicopter that tows it through the water at a constant rate of speed while it gathers data. Heat generated by the laser must be conducted through the outer hull of the underwater capsule to the surrounding ambient ocean water.

An earlier version of the system described at Photonics West is already in use for this LIDAR application, based on a pulsed laser and a time-resolved streak-tube receiver that allows high-resolution, three-dimensional ocean surveillance, either from submerged vehicles or from aircraft (see Laser Focus World, January 1998, p. 171).

"This isn't the most efficient laser, it's not the best performance laser, it's just average on all of those fronts, but it does those things over a wide varied range of temperature, vibration and all of that hard stuff that misaligns a laser," Kushina said. "So we've traded a lot of those performance markups for reliability. If you get a little more output you might damage a Q-switch. So we'd rather keep the beam spread out and keep the gain low."

The actual laser consists of a 2.5-mm diameter, Nd:YAG rod pumped by 36 gallium arsenide (GaAs) diode bars in a stable resonator. A 6-in.-long oscillator cavity was electro-optically Q-switched in a lithium niobate (LiNbO3) material to ultimately generate 5-ns pulses at 532 nm after frequency doubling. A semihemispherical cavity provides stable operation under dynamic forces; a flat output coupler enhances pointing stability; and zero-order waveplates contribute temperature stability. And temperature stability was the toughest aspect of the system design, Kushina said.

"The hardest thing in this program is keeping the diodes at just the right temperature. You've got to measure what the ambient is. You have to know where you are in temperature with respect to a spot on the diode heat sink," he said.

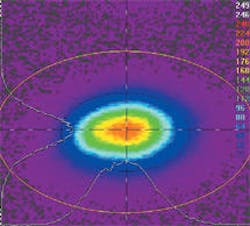

The diodes run right on wavelength at around 30°C, and maintaining that temperature is critical for optimizing pump beam absorption in the YAG rod to provide a consistent level of output pulse energy from the DPSSL. Heat distribution into the diode arrays was optimized using thermal finite element analysis and a resistance temperature detector in the system provides feedback for closed loop temperature control. The beam quality of the system has an M2 of less than 6 in the y-axis and less than 9 in the orthogonal axis (see figure).

While the blue-green wavelengths in this laser are necessary for underwater imaging, Arete Associates (Tucson, AZ), which integrates the solid-state lasers into the LIDAR surveillance systems is also seeing a growing market for remote object identification at other wavelengths for different environments.

"We've got a program with DARPA for doing very high-resolution imaging of objects under trees and camouflage," said John McLean, vice president and manager at Arete. "Just as in the water applications, the very high-resolution, three- dimensional aspect of it gives you an additional parameter that you can use to detect targets."

About the Author

Hassaun A. Jones-Bey

Senior Editor and Freelance Writer

Hassaun A. Jones-Bey was a senior editor and then freelance writer for Laser Focus World.