Despite safety improvements, automobile crashes still kill more than 40,000 people a year in the United States, and ten times that many worldwide. The ideal car, bus, or truck would be one that automatically avoids collisions. Now, after years of research, collision avoidance and automatic guidance systems have come into use on limited scale. Luxury cars are offering adaptive cruise controls (ACC) that maintain a safe distance from the car ahead, while busses in several cities are automatically steered.

Some of these "intelligent vehicles" use optical sensing devices such as laser range finders and video cameras. But the technology is still in flux with most systems involving radio or ultrasound sensors. The types of sensors that will ultimately come into general use is unclear but some combination of sensors are likely to be used in a mature technology.

From collision avoidance to automatic vehicles

The first intelligent vehicle technology to reach the commercial market has been adaptive cruise control, which uses either laser light or radar to measure the distance to a leading vehicle by timing the return signals (see Laser Focus World, October 2001, p. 32). Since laser light is reflected by rain drops and snow flakes, and radar is not, radar-based systems have the advantage that they can be used in bad weather, when collision avoidance is presumably most needed.

However, systems now in advanced stages of development combine optical and radar sensors for greater capabilities. In heavy traffic and on relatively tight turns, radar systems can become confused as to which car ahead is actually in the same lane as the driver's car and therefore poses a collision danger. Tracking and distinguishing many individual targets, which show up only as radar returns, is difficult with radar alone. However, a fusion sensor developed (as a prototype) by Fujitsu Ten (Plymouth, MI) uses a 640 × 480 pixel stereo video camera to identify and track individual cars, while radar measures the distance to each.

The camera detects vertical edges of objects, looking for the two ends of the leading cars rear bumpers. An algorithm calculates the angular width of objects from pairs of vertical edges. Using the distance provided by the radar returns, the algorithm then calculates the actual width of the object and its velocity relative to the driver's car. It eliminates objects that are narrower or larger than a car or are stationary. With only a few targets left, the algorithm can then pick out and follow the car in the same lane as the driver's, even around sharp turns. When the lead car suddenly slows, or another car enters the lane, the software can send an instruction to automatically apply the brakes in far less time than a driver can react. Fujitsu Ten expects the ACC based on its fusion sensor prototype to enter production in 2004.

But for public transportation buses, some systems are already moving to a higher level of automated control, with automatic steering.1 The Civis bus system, produced in France by Irisbus, a joint venture of Renault and Fiat, uses a video camera to guide the buses accurately and without driver input. The system is already in use in the French cities of Clermont-Ferrand and Rouen and will be introduced in Las Vegas, NV, in 2003.

The buses run in a special lane, next to the curb, that is prohibited to other traffic, except for right-turning vehicles. The buses run along virtual "rails"—stripes painted on the roadway that are detected by the video system. The cameras, which look about 100 ft ahead, feed software that adjusts the steering to keep the bus on track. A driver still controls the breaking and acceleration of the bus, although in the future that task could be taken over by collision avoidance systems as well.

There are several advantages to the optically guided buses. For one thing, the bus lanes are 5 ft narrower than those for use with human steering, a big plus for crowded city streets. The wheels on the buses are propelled by electric motors using electricity produced by a diesel engine. This arrangement eliminates the drive train and means that the bus platform is level with the curb, thereby eliminating all steps. In addition, the buses pull up to within two inches of the curb, so that wheelchairs can wheel right on to them without any ramps, resulting in savings in time.

The buses have additional features for commuter convenience. They are equipped with Global Positioning Satellite transponders that track their location and send signals to bus stops to tell passengers when the next bus is arriving. The French buses also allow the drivers to override traffic lights to speed up transit times.

Basically the guided buses function like trams or trolleys, except that there are no rails. The New Jersey Transit System is considering several corridors for possible use of the Civis system for rapid transit. Ironically, the system will duplicate some of the routes actually served a century ago by New Jersey's then-extensive trolley system, which covered the entire corridor between New York and Philadelphia. That system died when General Motors purchased it as a way to eliminate competition to the then-emerging bus industry.

In another effort to improve bus transportation, the San Mateo County Transit District in California is testing a Frontal Collision Warning System (FCWS) that uses a combination of laser range finders, radar systems, and ultrasonic sensors. The data from all three sensors are synthesized and software will warn the driver of impending danger, either to pedestrians or other vehicles. In a later stage, side-looking sensors will be added as well.

Sensing road conditions

While collision avoidance technology will only be introduced slowly as new cars and buses are bought, road hazard detection sensors can bring benefits far more quickly. The Japan Highway Public Corp. has been carrying out field tests of advanced systems of road condition sensors.

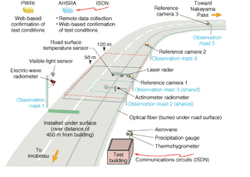

One of the test locations is at Nakayama Pass in Hokkaido, where heavy traffic of more than 10,000 cars daily has to navigate through harsh weather, including three months of heavy snowfall.2 Tests completed in September 2001 used four sensors: lidar, video, fiberoptic sensor, and millimeter wave radar (see Fig. 1). These tests indicated that the infrared (IR) sensor had the best overall performance in detecting changes in road conditions, but a combination of detectors may be better still. The IR sensor had the advantage of being able to operate in both daylight and night, unlike the video camera, and was not hampered by rainfall or snowfall, which affected the LIDAR. The system is capable of detecting eight different road conditions: dry, wet, water film, slush, new snow, compacted snow, compacted snow with ice crust, and ice film. In operation, drivers were warned of the conditions well in advance by electronic signs and speed limits were adjusted accordingly.Cooperative cruise control

Further into the future, cars may communicate directly with each other, allowing extremely fast reaction of following cars and allowing vehicles to travel much closer to each other, even at high speeds. Communications between the cars may be carried by LED, free-space lasers, or short-range radio.

In research performed at the California Partners for Advanced Transit and Highways, (PATH) a collaboration involving the California Department of Transportation, the University of California, and others, cars in a "platoon" transmit data on speed and acceleration to the other members of the platoon every 20 ms. The lead car travels at a set speed under cruise control, but any breaking or acceleration is communicated to the following cars, which automatically adjust to maintain their distance. In such platoons, the following distance, which depends on the capabilities of the cars and road conditions, could be as little as a few meters. If such platooning technology became widespread, the traffic capacity of a highway could be greatly increased. In the Path system, communication uses the Bluetooth wireless protocol, which is carried by radio. But the researchers are also developing an alternative using a modulated LED brake light (see photo at top of this page).3 Many difficult technical problems remain to be resolved, however, such as how to handle cars entering or leaving the platoon to switch lanes or enter or exit the highway.

Interestingly, there appears to be no current research efforts to combine automatic acceleration and breaking with automatic steering for personal vehicles, even though the technology would presumably be very similar to that already used for automatically steered buses. One reason could be automakers' reluctance to entirely remove the driver from control of the car, even on super highways. It might be difficult to combine "joy of driving" advertising campaigns with a fully automated system that turns drivers into passengers.

LEDs make inroads in new automotive applications

Light-emitting diodes (LEDs) have been used in automobiles for more than 20 years. The earliest uses were as simple on/off indicator lamps for dashboard control buttons. As the performance of LEDs began dramatic improvements in the mid-1980s, however, applications that required higher brightness were addressed for both exterior and interior functions.

The primary exterior use of high-brightness (HB) LEDs in automobiles is in center high-mounted stop lamps (CHMSLs). The use of CHMSLs is well established in the United States, Europe, and Asia, and LED-based CHMSLs are capturing an increasing share of the market. With 1/10th the power consumption of conventional incandescent lamp designs and significantly reduced turn-on time, LEDs offer significant advantages. Moreover, due to their vehicle-lifetime reliability, LEDs eliminate the need for incandescent-lamp warranty replacement, resulting in cost savings for the car manufacturer. The LED-based CHMSLs also provide a wider range of styling possibilities for automotive designers than do incandescent lamp-based products.

Only a very few car models, mainly in the luxury car category, have used LEDs for exterior signaling functions other than CHMSLs. The main impediment has been cost, but the situation is beginning to change as indirect cost factors and intangible benefits of LED lighting come to be more appreciated within the automobile industry.

The 2000 Cadillac DeVille was the first vehicle to go into production that utilizes HB LEDs for its rear combination lamps (RCLs) as well as for its CHMSL. Many of the benefits here are intangible-examples are the "jewel like" appearance of the RCL and the ability to provide the tail light function with a particular shape associated with the DeVille line. There are several tangible benefits that can be measured, however, including reduced electrical load, reduced mass, warranty savings, and mass production quality improvements.

Although the Cadillac DeVille is the only production vehicle with a complete LED rear combination lamp assembly, several other recent car makes and models have incorporated LEDs into various signal functions. These are primarily limited production luxury cars, such as the Mercedes S-Class, BMW 5-Series, and Nissan Gloria.

On the inside

During the past five years, the use of HB LEDs for interior car lighting has been a rapidly growing application. A major motivation for using LEDs for interior lighting is the short lifetime of incandescent lamps. If an incandescent amp in an instrument cluster has to be replaced, the entire dashboard must be removed—an expensive and time-consuming process for the owner and one that could result in a significant warranty payment by the manufacturer. The long life of LEDs makes them a perfect match for the extended warranties that car companies are now offering.

A second reason for using LEDs in interior lighting is vehicle manufacturing cost. Even though LEDs are much more expensive than comparable incandescent lamps, monetary savings can be achieved in other associated systems. Some car models that use incandescent lamps for instrument panel functions have complex light-piping systems that are quite expensive. In these cases, it can be cheaper to use LEDs because a light piping system would not be needed. Light emitting diodes are available in surface-mount and edge-emitter forms that simplify the light piping needed or eliminate it altogether. The use of surface-mount LEDs lends itself to automated dashboard assembly, which uses wave soldering for various electronic components. Until now, the use of HB LEDs in car interiors is primarily in Europe, and can be seen in most German car makes, including Volkswagen, Mercedes, BMW, and Audi, as well as other European models. In the USA, the new Lincoln Navigator uses LEDs for its instrument panel lighting.

- www.nytimes.com/2001/07/26/technology/circuits/26NEXT.html?ex=996811200&en=2151d5cf93b69cb3&ei=5040&partner=MOREOVER

- www.netpark.or.jp/ahs/eng/c04e/5th/kasuga_e/kasuga_e.htm

- www-path.eecs.berkeley.edu/PATH/Publications/PDF/PRR/2001/PRR-2001-31.pdf

Eric J. Lerner | Contributing Editor, Laser Focus World

Eric J. Lerner is a contributing editor for Laser Focus World.