MARTYN KNOWLES, ANDREW KEARSLEY AND DIMITRIS KARNAKIS

Lasers have been used for micromachining since the early days when power was measured in “Gillettes”-the number of razor blades a laser could drill through. Along with the ensuing development of lasers, processing knowledge also advanced, and lasers now are widely used in a vast number of micromachining applications. In selecting the most appropriate laser for a micromachining task, however, several factors must be considered.

Pulsed lasers are used to machine parts with features having dimensions measured in microns with tolerances on the order of 1 µm. Typically, a short, high-peak-power pulse of light is focused onto the surface of the part. The material at the focus of the beam is quickly heated past the melting point and a portion is vaporized. The resulting pressure wave ejects the molten material-as high-velocity microdroplets-leaving a micropit typically 5 to 10 µm across and 1 to 5 µm deep. A high-repetition-rate laser is used to achieve a reasonable material removal rate. Larger features are machined by moving either the workpiece or the laser beam.

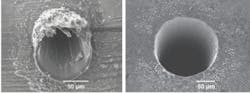

Other important process considerations include “recast,” which is material that has been melted but resolidifies in the hole; “cracking,” which can take place in solidifying recast material; “dross,” which consists of expelled droplets that can fly out of the hole but adhere to the surface next to the hole; and “heat-affected zone” (HAZ), which refers to an area around the hole where residual heat can cause thermal changes in material structure. All these factors are affected by the pulse duration, the wavelength, and the process used. Process optimization plays a vital role in micromachining performance but is often ignored in laser comparison studies (see Fig. 1).

Pulse duration effects

In general, long pulses allow more heat to diffuse into the surrounding material and produce larger thermal effects. Shorter pulses reduce thermal damage. In addition, short pulses have very high peak powers, which produce more vapor and less molten material, thereby reducing the amount of dross and recast. Research using ultrashort-pulse lasers in the femtosecond regime has confirmed that shorter pulses offer significant advantages in terms of recast, cracking, HAZ, and dross. In the absence of any other factors, femtosecond lasers would appear to be ideal. This is seldom the case in practice, however.

While the process benefits of shorter pulses are clear, great care must be taken in interpreting the results of research studies that simply compare laser performance. When two lasers are compared, the process must be optimized in both cases because subtle process differences can have gross effects on quality. Consequently, research studies that do not include appropriate process optimization are prone to greatly exaggerate the benefit of short-pulse lasers and the limitations of nanosecond lasers.

Emerging workhorses

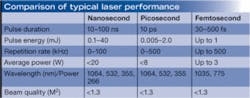

Cost-effective industrial processes require high machining rates and reliable, low-maintenance lasers, typically of nanosecond, picosecond, or femtosecond class (see table). In general, the following guidelines apply (with some notable exceptions): shorter pulses produce less heat damage, shorter wavelengths remove less material per pulse, shorter pulses remove less material per pulse, higher-energy pulses remove more material per pulse, higher-energy pulses create more dross and HAZ, less material removed per pulse means higher precision, less material removed per pulse requires higher pulse repetition rate

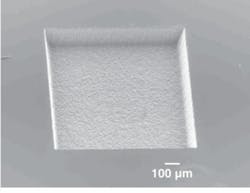

Largely due to their cost-effectiveness and reliability, nanosecond lasers have become industry workhorses. Most work is done using pulse durations in the 10 to 100 ns range and output powers up to 20 W. Typical applications of IR and visible lasers include microdrilling, microcutting, and micromilling of metals and ceramics (see Fig. 2). Nanosecond UV lasers are generally used to machine plastics to avoid heat damage, and in microelectronics applications. For example, 355 nm, third-harmonic Nd:YAG lasers are very good for machining polyimide. The majority of industrial laser systems sold by Oxford Lasers are based on nanosecond lasers.

There are a number of applications, however, in which even UV nanosecond lasers are unable to produce good results, such as machining Teflon or glasses. In principle, femtosecond lasers provide a solution for most of these applications. The extremely high peak power means that nonlinear effects allow strong absorption even in transparent materials, enabling difficult materials to be machined. At the same time the very short pulses avoid thermal damage.

Unfortunately, femtosecond lasers have significant disadvantages. To date, most femtosecond lasers give high pulse energies at comparatively low repetition rates. The extremely high peak power tends to create a plasma at focus. The fireball is comparatively long-lived and significant thermal damage can result from the long-lived plasma. If the pulse energy is reduced to eliminate these effects, the material removal rate becomes extremely slow. Femtosecond lasers also tend to be complex, expensive, and high maintenance, making them unattractive for industrial use except where they are the only solution and the user fully understands their limitations. Therefore, while femtosecond systems are valuable research tools, they are not widely used in industry.

As it turns out, the laser industry jumped straight from nanosecond to femtosecond lasers without fully examining picosecond sources for micromachining. Recently it has been realized that picosecond lasers offer most of the advantages of femtosecond systems, while avoiding the problems (see “Picosecond lasers work well for laser micromachining,” above). Picosecond lasers offer precision and low thermal damage because relatively low pulse energy with very high repetition rates results in high material removal rates while avoiding plasma problems. Consequently, in recent years, companies such as Lumera Laser (Kaiserslautern, Germany) and Oxford Lasers have developed picosecond lasers for micromachining.

Picosecond lasers are extremely good at drilling, cutting, and milling difficult materials.1, 2, 3 They produce minimal thermal damage and very little dross, making it significantly easier to get good results even in the case of materials or features that are very hard to machine with a nanosecond laser. Micromilling, for instance, is a challenging application for nanosecond lasers. Good sidewalls can generally be obtained, but the bottom of the feature is often rough with a layer of dross and recast material. In contrast, picosecond lasers give very clean results and a much smoother surface (see Fig. 3).

A number of industrial applications have been developed using picosecond lasers and many more are under development; for example, microelectronics companies are using multiple picosecond lasers for very high-precision metal and ceramic processing. While picosecond lasers are very expensive compared to nanosecond sources, they offer reliability. And prices are likely to fall as the market grows and additional manufacturers begin to offer picosecond sources. Significant increases in power from commercially available picosecond sources is expected in the second half of 2007, and industry experts predict that about 100 picosecond lasers will be sold for micromachining in 2007.

REFERENCES

1. D.M. Karnakis et al, Photon Processing in Microelectronics and Photonics V. Proc. of SPIE6106, 610604 (2006).

2. D.M. Karnakis et al., Proc. Third Intl. WLT Conf. on Lasers in Manufacturing 2005, Munich (June 2005).

3. B. Klimt, Industrial Laser Solutions (December 2006).

MARTYN KNOWLES is technical director, ANDREW KEARSLEY is R&D director and deputy chairman, and DIMITRIS KARNAKIS is project leader at Oxford Lasers, Unit 8, Moorbrook Park, Didcot, OX11 7HP, England; e-mail: [email protected]; www.oxfordlasers.com.

Picosecond lasers work well for laser micromilling

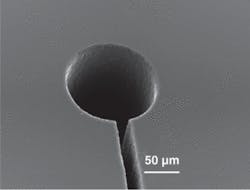

Direct laser micromachining can produce prototypes or small numbers of microparts. However, it is generally too slow for mass production. Micromolding is a mass-production technique of considerable promise, but the molds need to be manufactured in hard materials such as tool steel, tungsten, ceramics, or silica.

Laser micromilling is of considerable interest for mold manufacture. However, it is a challenging application for nanosecond lasers. The tightly focused beam is equivalent to machining with a sharp pointed mill. It is almost impossible to eliminate the grooves that result as the beam is scanned over the surface, unless very closely spaced scans are used, in which case the process speed is low. Melting and redeposition gives a relatively rough base covered in a thin layer of dross and recast. While the quality is acceptable for many applications, better surface finishes are often required. In addition very careful optimization of the process is required for each material and mould shape.

Picosecond lasers have a number of advantages in micromilling. The very high repetition rate allows high-speed scanning, with tracks close together, reducing the grooving effect while maintaining a high process speed. In addition, the dross and recast is significantly reduced. As a result, a much-improved surface finish can be obtained, often with a higher process speed.

Further, picosecond lasers offer a second advantage: hard-to-machine materials can be processed with relative ease. For example, fused silica is very hard to machine with conventional nanosecond lasers, but picosecond lasers machine silica with ease, and process optimization is relatively simple and very similar to that used for metals.1 A superficial roughness approaching 0.1 µm has been achieved in glassified carbon.

REFERENCE

1. D.M. Karnakis, M.R.H. Knowles, P.V. Petkov, T. Dobrev, S.S. Dimov, “Surface integrity optimization in ps-laser milling of advanced engineering materials.” To be presented this month at 4th international WLT Conference on Lasers in Manufacturing, 2007, in Munich, Germany.