JOHN B. HUT and EGON PFEIFER

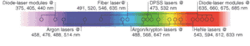

Confocal laser-scanning microscopy (CLSM) serves a variety of applications in the life-sciences market, including medical and cancer diagnostics as well as materials analysis. This microscopy technique draws on a wide range of laser technologies for high-quality coherent light sources. Traditionally using gas lasers, CLSM now takes advantage of the range of wavelengths offered by argon, argon/krypton, He-Ne, and helium-cadmium lasers, as well as diode and diode-pumped solid-state (DPSS) lasers (see Fig. 1).

Gas lasers: still the workhorse

Known for their long-term stability, long lifetimes, low cost, and exceptional beam quality, gas lasers such as argon and helium-neon lasers are still used in large numbers. With years of experience and established data on lifetimes, original-equipment manufacturers (OEMs) of confocal microscopes have continued to design gas lasers into their new systems. Those OEMs that have experimented with alternative technology have experienced mixed results at times, returning to traditional, proven methods for fluorescence-based instruments.

The most compelling reason for the continued success of argon and argon/krypton lasers is their ability to emit multiple wavelengths from a single unit. Spanning the blue, green, yellow, and red wavelengths, ion lasers are difficult to replace economically and efficiently.

Advances in laser-system design and production have contributed to the success that ion lasers continue to enjoy. Internal-mirror, hard-sealed argon, and now argon/krypton lasers have virtually eliminated the need for field servicing due to contamination and misalignment of old, external-mirror lasers. Enhancements in laser design have also extended lifetimes of argon-ion lasers; further advances in designing smaller, more compact gas lasers and power supplies have played a role as well.

A larger, more significant issue remains cost of operation. Gas lasers offer a cost advantage for CLSM manufacturers in designing new laser-based microscopes when compared with solid-state lasers. Replacing a single argon laser with diode or diode-pumped technology would require up to four solid-state lasers to cover the blue and green wavelength spectrum. Replacing a krypton laser used for photobleaching as well as fluorescing dyes has proven difficult as frequency-doubled solid-state lasers increase costs significantly.

Beam quality over the life of the laser is also a critical factor when selecting laser technologies. Gas lasers continue to offer the highest beam quality when considering factors such as Gaussian distribution and ellipticity of the laser beam.

Recently, OEMs are closing the gap that has existed between green and red excitation wavelengths by taking further advantage of He-Ne lasers. Offered in the yellow/orange wavelengths, He-Ne lasers can be used in combination with common fluorescent dyes such as Texas Red, as well as Alexa 633.

Drawbacks to using gas lasers include their large size and weight relative to newer technology. Heat dissipation, optical noise, and vibration caused by the heat exhausted from argon and argon/krypton lasers also contribute to the continued demand for alternative light sources.

The racehorse

As solid-state lasers mature, their use in confocal microscopy is expanding rapidly. Given their extremely compact packaging and low heat dissipation, solid-state lasers offer simple OEM integration and a more complete range of wavelengths spanning the UV to IR spectrum. Instruments used with fluorophores are increasingly equipped with solid-state lasers that are both much smaller and much more energy efficient than the argon-ion lasers that were formerly commonplace (see Laser Focus World, January 2003, p. 87).

Solid-state lasers boast a variety of technical achievements that benefit applications like confocal microscopy. Lower noise levels, critical for CLSM, are realized using higher-quality diode and diode-pumped lasers. Diode and DPSS technologies require a fraction of the input power traditionally needed to run ion lasers. Diode-pumped solid-state technology has also widened the application potentials, as wavelengths like 532 nm are used for materials research.

Perhaps the most compelling argument for solid-state-laser use over gas lasers is their potential for increased lifetimes. Estimates of greater than 20,000 hours are becoming a reality. Advances in diode manufacturing are aiding this cause. The market for DPSS lasers has experienced robust growth over the past decade (see Laser Focus World, February 2003, p. 72). As diode manufacturing increases, manufacturers find more efficient means of producing diodes and increasing yields. The result has been more affordable components.

Modules replace and enhance

Diode modules are compact, cost-effective solutions to filling in the UV and violet wavelengths used in CLSM. Offered in three primary wavelengths—375, 405, and 440 nm—diode modules are quickly replacing older water-cooled argon and helium cadmium lasers. In addition to UV and violet, diode modules are beginning to replace red He-Ne lasers at a variety of wavelengths from 635 to 690 nm. Of particular interest to confocal microscope users are the 635- and 675-nm wavelengths.

Diodes are typically thermoelectrically cooled to achieve optimum mode quality and wavelength selection. Beam-shaping optics are included to circularize the beam. The lasers are packaged with a controller and require very low input voltage.

Violet laser-diode modules are valuable, cost-effective replacements for large ion lasers. Imaging with fluorophores such as DAPI and Hoechst is now possible using a laser that is a fraction of the size (for example, 178 × 75 × 56 mm) of a water-cooled UV argon laser. New compact diode modules can now be used for fluorescence-resonance-energy-transfer imaging with no service or maintenance required.

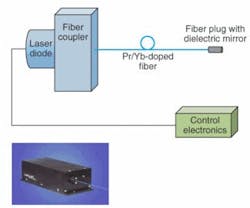

Fiber lasers at blue and green

Fiber lasers offer a variety of visible wavelengths, typically including blue (491 nm), green (520 or 546 nm) and red (635 nm), depending on the fiber and the resonator design (see Fig. 2). Because the infrared pump diode is directly converted into visible light, the fiber laser has a compact design and fewer components than diode-pumped or optically pumped solid-state lasers, with low power consumption and lower heat dissipation also.

Of special interest is the 491-nm wavelength because it can directly replace the single-line 488-nm argon laser. An example fiber laser emits 10 mW at 491 nm with a total power consumption of less than 15 W. Fiber lasers at 546 nm can enhance applications that have traditionally used green HeNe lasers, tripling the output power to 10 mW.

Direct-doubled to blue

Expanding solid-state technology has made other blue wavelengths available as an alternative to air-cooled argon-ion lasers; 458-, 476-, and 488-nm wavelengths can now be reached using direct-doubled diode and diode-pumped solid-state lasers. These lasers can now produce the exact (or very close) wavelength needed for fluorescent dyes. Designed for telecommunications applications, direct-doubled diode lasers are beginning to make inroads on blue solid-state lasers (see Laser Focus World, December 2003, p. 93).

John B. Hut is marketing manager for National Laser Company, 175 West 2950 South, Salt Lake City, UT 84115. Egon Pfeifer is managing director of Lasos Lasertechnik, Carl-Zeiss-Promenade 10, 07745 Jena, Germany. John Hut's e-mail: [email protected].