Extreme-ultraviolet (EUV) lithography is considered an attractive candidate to succeed conventional optical lithography in the coming years (see Laser Focus World, February 2003, p. 55). Its wavelengths of approximately 13 nm would allow the reduction of structure sizes to less than 100 nm in semiconductor devices. To enable this technology, a high-intensity light source that emits in the correct EUV range is required. One promising solution has been found in laser-produced plasmas (LPPs). Engineers at Powerlase (Crawley, England) specialize in this technology and have developed lasers that are already finding commercial applications in industry.

Plasmas emit radiation, and the peak wavelength of the light emitted is determined by the temperature of the plasma. The optimum temperature can be estimated using a blackbody formula. Laser-produced-plasma schemes use laser radiation to heat a target to the optimum temperature required for efficient EUV production. The focused laser light transfers its energy into the target in such a way that a plasma is formed. A wide range of targets is available for use in LPP schemes, ranging from gaseous and cluster targets in the range of 0.1 to 10 nm in diameter to micron-sized liquid targets and macroscopic solid targets.

Extreme-ultraviolet sources based on LPPs have several advantages over discharge-based EUV sources. For example, there is power scalability through the tuning of laser parameters, low debris, good dose control if there is good pulse-to-pulse stability, flexibility in dimensions, spatial stability, minimal heat load, and a large solid angle of collection.

The EUV emission from an LPP source depends on the target density, composition and dimensions, as well as on the laser parameters. To optimize the conversion efficiency of laser energy into EUV radiation, the laser parameters of pulse duration, laser energy per pulse, time-averaged power, and focal-spot size must be tailored to suit the chosen target. The optimum laser-pulse duration is between 1 and 20 ns, depending on plasma conditions and dimensions. The optimal laser focal-spot size depends on laser pulse energy as well as the target medium. In a xenon gas target, a spot size of between 50 and 500 µm is ideal for laser pulse energy between 50 and 500 mJ.

Many beams, one target

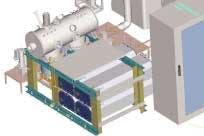

Powerlase has developed high-power diode-pumped solid-state lasers to drive this technology forward. The company uses a modular approach, combining the beams of many units in an optical system it has designed for the application. This achieves the necessary laser parameters on the target. A refractive optic focuses the multiplexed beam on to the gas jet target. Each of the component beams focuses to the same point and with the same beam diameter at focus, so the energy on the target is proportional to the number of laser modules combined.

Each Powerlase gain module cavity delivers more than 400 W in a cavity that is acousto-optically (AO) switched at up to 50 kHz. This AO version can produce pulse lengths of 25 to 200 ns and pulse energies up to 60 mJ. In a different configuration, each module can produce more than 150 W in an electro-optically (EO) switched cavity at 3.5 kHz, with similar pulse energies but shorter pulse lengths of less than 10 ns. The design of the units results in an electrical-to-optical efficiency of up to13% for a beam quality M2 of 10.

In the initial setup, a number of EO-switched lasers, each with a pulse length of 9 ns, are spatially multiplexed in order to reach the required laser irradiation conditions on target. But Powerlase has not ruled out the AO-switched systems for systems that are scaled to higher EUV output powers. By spatial multiplexing of multiple laser modules, it remains possible to achieve and exceed the required intensities, albeit with an expected lower conversion efficiency from laser to EUV.

Powerlase has a roadmap for equipment development to get to commercially usable EUV powers in time for EUV lithography production tools. The system is currently configured for 450 W of multiplexed laser power to produce 2.3 W of EUV in the correct wavelength region, of which around 1 W is collected and ready to be used. By the end of this year the company hopes to have 4.8 kW of laser power producing around 14 W of usable and collected EUV. By 2006, the company hopes to have sources producing as much as 90 W of collected in-band EUV.

Light traveling inside glass reflects at certain angles off the glass/air interface back into the glass with no loss, a phenomenon called total internal reflection (TIR). Placing a substance against the outside of the glass, however, can frustrate this process and cause the light to be transmitted through the glass surface and into the substance. This effect forms the basis of a type of display being developed by researchers at the University of British Columbia (UBC; Vancouver, BC, Canada).

The technique has antecedents, according to Robin Coope, one of the researchers. For example, a successful demonstration of actively controlled reflection was done by Jacob Tellerman of the Kollsman Instrument Company (Elmhurst, NY), says Coope. Tellerman received a patent in the early 1970s for an aircraft readout using rubber-tipped metal pins in contact with frosted glass. The metal would change length in response to magnetic fields and the rubber would go into and out of contact with the glass. But, though the technique achieved variable reflectance, it was not based on TIR, notes Coope.

To controllably switch TIR on and off, the UBC researchers start with a retroreflective polymeric sheet containing a large array of microprism corner cubes, which reflect most of the light hitting them (imperfect construction and other effects prevent perfect reflection). If a soft material with the proper properties is pressed against the back of the retroreflective sheet, the material contacts the microprisms, filling in the voids and letting the light pass through.

Finding the right soft material was not easy, but the researchers settled on a polydimethylsiloxane gel, which they treated with ozone to crosslink and harden the surface while leaving the underlying material compliant. Carbon black was added to the gel to absorb light. To switch the reflectivity off and on, pneumatic pressure was applied behind the gel membrane to force it against the sheet and switch off TIR; lowering the pneumatic pressure allowed separation and the reemergence of TIR (see figure). Even after 10,000 cycles, the gel returned to its original position. Switching time was about 0.25 s, with reflectivity changing between 75% and 25%.

But the UBC researchers believe this arrangement is unwieldy for many applications, and therefore are pursuing another approach. "We have investigated the use of electrophoresis to control the position of absorptive pigment particles, and this approach has demonstrated some very promising results, including the ability to achieve a full-color reflective display with up to a fourfold improvement in reflectance over current displays," explains Michele Mossman, a member of the group.

Such an approach may sound superficially similar to that of E-Ink (Cambridge, MA), a company that has commercially introduced electrophoretic displays with great success. But the E-Ink displays don't depend on switching TIR to achieve reflectivity or color changes; instead, they directly rely on the movement of colored or black and white particles within tiny, fluid-filled capsules to change the appearance of the display. Because TIR is such a strong effect, switching it on and off as in the UCB devices can potentially result in large changes in display contrast from particle movements that are very small.

REFERENCE

- R. J. N. Coope et al., Applied Optics (Sept. 1, 2002).

Bridget Marx | Contributing Editor, UK

Bridget Marx was Contributing Editor, UK for Laser Focus World.