As solid-state lighting—a close relative of photovoltaics—becomes poised to whittle away at the power demands of established metropolitan lighting systems, it is also creating small and remote market pathways for solar power. A conference held in Denver, CO, in March, under the auspices of the National Renewal Energy Laboratory (NREL; Golden, CO), focused on increasing the synergistic effects between solid-state lighting and solid-state power generation.

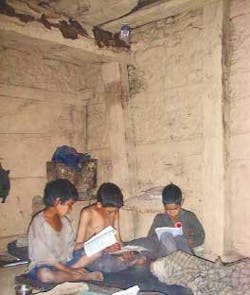

David Irvine-Halliday, founder of the Light Up The World Foundation (Calgary, Alberta, Canada) described the introduction of solar-, wind-, water-, and pedal-powered 1-W light-emitting-diode (LED) lighting systems into remote, rural villages that lacked illumination in India, Nepal, and Sri Lanka, as a source of both artificial light and local private enterprise (see Fig. 1). David Green, founder and chairman of Carmanah Technologies (Victoria, British Columbia, Canada) described how relatively humble power requirements along with increasing lumen output of LED illumination technology has created a market for efficient solar-powered nautical markers and navigation lights that is also finding numerous other applications (see Fig. 2).

"If you install a flashing light along the side of a roadway, you can either deal with the whole mess of contacting the power company, having someone turn off the electricity to drop a wire connection, and then figuring out who is going to pay for the electricity, or you can buy a flashing light system that that has a photovoltaic panel and a battery attached," said Sarah Kurtz, an NREL scientist and organizer of the March meeting, who also gave a presentation on solid-state lighting and photovoltaic synergies.

Similarities and differences

Kurtz referred to solid-state lighting in this context as an enabling technology that enables the use of photovoltaics in applications for which photovoltaics would not otherwise be cost-effective. "My primary objective for this meeting was to educate solar-cell specialists about the recent advances in solid-state lighting and to stimulate their interest enough that they will take note of new developments when they run across them," she said.

In her presentation, Kurtz emphasized similarities between solid-state lighting and photovoltaic technologies. While solar cells generate electricity from light and LEDs generate light from electricity, both are based on diode structures with carriers confined to active regions, and both are designed to allow light to pass efficiently between the semiconductor and its surrounding environment. In addition, III-V material systems currently provide the highest efficiencies in both cases, while organic material systems may, with further development, offer reduced cost without sacrificing performance by lessening the sensitivity of devices to defects in crystalline structure.

Emphasizing and promoting awareness of such similarities, through linking topics at scientific meetings for instance, is likely to contribute to the pace of technology development in both fields and to assist policymaking decisions, she said. In the case of the U.S. Department of Energy, limited resources must be spread over diverse objectives that include supporting market development, accelerating incremental improvements in current technology, and investigating new and potentially revolutionary technologies.

In addition to recognizing similarities between the technologies, more-effective technology development and wiser policy making also requires an understanding of the differences between technologies, according to James Gee, a senior scientist at Sandia National Laboratories (Albuquerque, NM) with experience in photovoltaics and solid-state lighting.

"The biggest difference between the two technologies is the strength of what I would call the interim high-value markets for light emitting diodes," he said. "That has led to a far faster growth rate and growth revenues, and probably a far-healthier industry overall, than has been traditional in the photovoltaic area. The net result is that the LED community already has worldwide revenues that exceed those of the photovoltaic community for modules. And it has achieved those revenues in less than eight or nine years, compared to 20-plus years of work in the photovoltaic industry."

Strong markets, growth rates, and profit margins fuel rapid technological growth by allowing companies to support their own research and development and to take risks, he said. "If the initial blue LEDs, for example, were only one percent efficient, that was still valuable to someone," he said. "The same would not be true if you're talking about solar cells."