LEDs: Phosphor-converted white LEDs have almost no conversion loss

White-light light-emitting diodes (LEDs) are typically created either from blue- or near-ultraviolet-emitting chips coated with a yellow phosphor, or from red-green-blue systems that mix light from multiple monochromatic LEDs. The phosphor approach is a more-mature technology, and lends itself to brighter, more efficient, and relatively low-cost, high-volume manufacturing. Solid-state-lighting goals set by the Department of Energy and the Optoelectronics Industry Development Association have spurred advances in the efficiency and color quality of phosphor-converted white-light LEDs (pcLEDs), which typically appear bluish to the eye. Now, scientists at the Nanoelectronics Laboratory at the University of Cincinnati (Cincinnati, OH) have obtained a blue-to-white conversion loss of only 1% with a suite of improvements to a phosphor-based white LED design.1

Professor Andrew Steckl at the University of Cincinnati and graduate student Steven Allen (currently senior engineer at Osram Sylvania, Danvers, MA) reported a “nearly ideal” phosphor-converted white-light luminaire, labeled “enhanced light extraction by internal reflection” (ELiXIR). A high-efficiency 460 nm LED from Cree (Morrisville, NC) was the source of blue light in the ELiXIR luminaire, which was mounted on an aluminum base and placed inside a hemispherical optic shell of poly(methyl methacrylate) (PMMA). The hemispherical shell encapsulated a film of high-efficiency, index-matched, semitransparent, fluorescent dye phosphor, separated from the blue LED by an air gap. The floor of the light fixture consisted of a high-reflectivity (R greater than 98.5%) specular reflector.

Dispersed orange dye layer

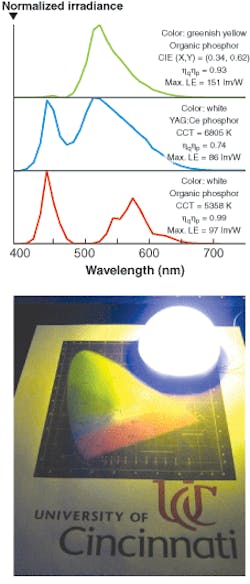

The researchers created several versions of the luminaires, a green and two white, but the most promising in terms of conversion efficiency was a white luminaire with an organic orange fluorescent dye layer dispersed in a modified PMMA shell (see figure). The high-efficiency orange organic phosphor was semitransparent, delivering the maximum luminous efficacy (LE) possible, but resulting in a narrower emission spectrum. The maximum LE of the white luminaire with the orange phosphor was 97 lm/W at 30 mA, with emission occurring in two broad peaks at approximately 450 and 580 nm.

The loss in a pcLED typically derives from two sources after photons leave the LED chip: a nonideal quantum efficiency for the phosphor (ηq), and a nonideal efficiency for the packaging of the device (ηp). Conversion efficiency (CE) is the product of ηq and ηp. An ideal pcLED system will have 100% of the photons emitted by the chip converted to light: in other words, CE = 1. The white ELiXIR pcLED with an organic orange-emitting phosphor achieved a ηp of 0.99—the highest value yet reported for a pcLED. In comparison, the green luminaire, incorporating a yellow organic fluorescent dye phosphor layer, had a CE of 0.93 and a maximum luminous efficiency of 151 lm/W.

One secret to the ELiXIR luminaire’s near-ideal CE is the placement of the phosphor at a “remote” intermediate location, in between the exterior surface of the encapsulating sphere and the air gap around the chip. The location is a balance between the need to minimize the amount of phosphor emission scattered back toward the chip and the need to maximize the number of photons hitting the phosphor at a normal angle of incidence. The phosphor/air interface acts as a simple optical filter that transmits LED light striking at normal incidence, yet largely reflects isotropic phosphor emission by internal reflection. Photons that hit the phosphor at a direct angle are less likely to be absorbed by the phosphor.

“This placement of the phosphor is exactly what is needed to direct both LED and phosphor-emitted light out of the device and away from the lossy LED chip and mirror reflector,” said Allen. “Both the optical design and choice of phosphor layer materials are critical in achieving high efficiency.” According to Steckl, the university is actively seeking industrial partners for commercialization or licensing of the technology.

REFERENCE

1. S.C. Allen and A.J. Steckl, Appl. Phys. Lett. 92, 143309 (2008).

Valerie Coffey-Rosich | Contributing Editor

Valerie Coffey-Rosich is a freelance science and technology writer and editor and a contributing editor for Laser Focus World; she previously served as an Associate Technical Editor (2000-2003) and a Senior Technical Editor (2007-2008) for Laser Focus World.

Valerie holds a BS in physics from the University of Nevada, Reno, and an MA in astronomy from Boston University. She specializes in editing and writing about optics, photonics, astronomy, and physics in academic, reference, and business-to-business publications. In addition to Laser Focus World, her work has appeared online and in print for clients such as the American Institute of Physics, American Heritage Dictionary, BioPhotonics, Encyclopedia Britannica, EuroPhotonics, the Optical Society of America, Photonics Focus, Photonics Spectra, Sky & Telescope, and many others. She is based in Palm Springs, California.