Quantum Dots: Liquid-state quantum dot white LEDs have high luminous efficiency

Researchers at Koç University (Istanbul, Turkey) and PSR Arts and Science College (Sivakasi, India) have demonstrated quantum-dot (QD)-based white LEDs that exhibit a record luminous efficiency of 105 lm/W for green/blue light generation and 64 lm/W for red-green-blue (RGB) light generation.1 With further development, the new LEDs could reach efficiencies over 200 lm/W, making them a promising energy-efficient lighting source for homes, offices, outdoor lighting, and displays.

The new LEDs use commercially available blue LEDs combined with flexible lenses filled with a solution of semiconductor QDs. Light from the blue LED causes the QDs to emit green and red, which combines with the blue emission to create white light.

Although QDs embedded in a film are currently used in LED-backlit televisions, such a lighting approach is not suitable for widespread use in general lighting applications. Transferring the QDs in a liquid allowed the researchers to overcome the problematic drop in efficiency that occurs when nanomaterials are embedded into solid polymers.

Making efficient white LEDs requires QDs that efficiently convert blue light to red or green. The researchers carried out more than 300 different synthesis reactions to identify the best conditions, such as temperature and time of the reaction, for making QDs that emit at the correct colors while exhibiting optimal efficiency.

To make the new LEDs, the researchers filled the space between a polymer lens and LED chip with a solution of QDs that were synthesized by mixing cadmium, selenium, zinc, and sulfur (Cd, Se, Zn, and S) at high temperatures. The green-emitting QDs had a CdSe//ZnS/CdSZnS core/shell structure, while the red-emitting QDs had a CdSe/CdS/ZnS core/shell/shell structure. The syntheses of both the red- and green-emitting QDs were each repeated three times to ensure that the results were repeatable. Center emission wavelengths for the green- and red-emitting QDs were about 550 and 615 nm respectively, with bandwidths of about 35 nm.

Injecting silicone

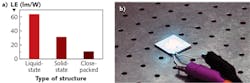

The researchers used a type of silicone to make the LED lenses because its elasticity allowed them to inject solutions into the silicone lens without any solution leaking out, and the material’s transparency enabled the necessary light transmission. A silicone elastomer and curing agent were poured into an aluminum mold and heated to 70°C for six hours to make the lenses which has a semispherical geometry with an outer diameter of 9 mm, an inner diameter of 7 mm, and a lens thickness of 1 mm. For experimental comparison, LED with QDs in a solid-state film were also fabricated, as well as LEDs with close-packed QDs.

The researchers showed that their liquid-based white LEDs could achieve an efficiency double that of the LEDs that incorporated QDs in solid-state films. While the solid-state and close-packed LEDs had luminous efficiencies of 31 and 11 lm/W, respectively, the liquid QD LED achieved 64 lm/W (see figure).

The researchers further demonstrated their white QD LEDs by using them to illuminate a 7 in. display panel, leading to bright and vivid images. The external quantum efficiency was measured over a 100 h period and was shown to be stable over that time.

“As a next step, we will further improve the efficiency levels of QD-based white LEDs,” says Sedat Nizamoglu, one of the researchers, who is a scientist at Koç University. “In addition, we will work on high-efficiency LEDs that incorporate eco-friendly nanomaterials without any cadmium and lead content. We aim to demonstrate a version combining state-of-the-art blue LEDs with QDs having 100% emission efficiency. For that, we need to further work more on the optimization of the synthesis of QDs and we need to also collaborate with other research groups that can develop efficient blue LEDs as well. The combination of the blue LEDs and QDs with careful device engineering will generate ultra-efficient light sources.”

REFERENCE

1. S. Sadeghi et al., Optica (2018); https://doi.org/10.1364/optica.5.000793.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.