Fiber-laser in-band pumping enables novel 2 μm high-power short-pulse laser

Highly efficient high-power short-pulse lasers in the 2 μm wavelength range based on thulium (Tm3+)-doped materials have a variety of applications that include materials processing (such as polymer-to-metal joining), lidar, mid-infrared (mid-IR) optical parametric oscillators (OPOs) that produce wavelengths up to 12 μm, and mid-IR supercontinuum generation. They also would enable direct coherent soft x-ray generation via high-order harmonic generation (HHG). For these applications, a light source with much higher conversion efficiency, average power, pulse energy, and shorter pulse duration is desirable.

Now, Masaki Tokurakawa and colleagues at the Institute for Laser Science, University of Electro-Communications (UEC; Tokyo, Japan) have developed novel 2 μm high-power short-pulse lasers based on a new technique of fiber-laser in-band pumping at 1611 nm and Kerr-lens mode locking with a new Tm-doped gain medium provided from the University of Hamburg by researcher Christian Kränkel.

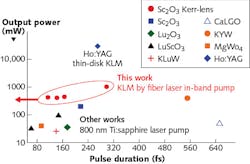

Pulses as short as 115 fs and an output power of 420 mW with a conversion efficiency of approximately 20% were obtained. At a longer pulse duration of 298 fs, the laser reached an average power of more than 1 W. Compared with prior semiconductor saturable-absorber mirror (SESAM) mode-locked Tm-doped lasers pumped by titanium:sapphire (Ti:sapphire) lasers, this new method enabled generation of much higher output power and shorter pulse duration with higher conversion efficiency. The researchers say that this is the first Kerr-lens mode-locking at a wavelength of 2 μm, opening up possibilities for new highly efficient high-power short-pulse lasers at 2 μm. In the future, sub-50-fs pulse generation at this wavelength range is possible. Reference: M. Tokurakawa et al., Opt. Lett., 42, 3185–3188 (2017); https://doi.org/10.1364/OL.42.003185.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.