One way to increase semiconductor laser light output while at the same time maintaining diffraction-limited beam quality is to coherently couple two or more lasers together. Such a task is not easy: for two decades, researchers have struggled to coherently couple edge-emitting laser diodes together, with increasingly successful results (see Laser Focus World, July 1999, p. 13). The vertical-cavity surface-emitting laser (VCSEL) has qualities that make it a natural candidate for coherent coupling: not only does it produce a circular beam, but it can be made into large two-dimensional (2-D) arrays. However, attempts to coherently couple VCSELs have not produced stable, high-power, high-quality beams.

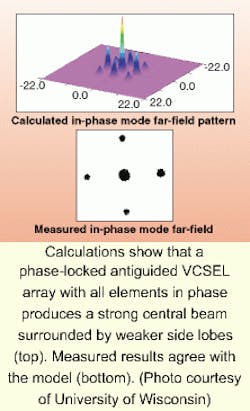

In results presented at the IEEE International Semiconductor Laser Conference (ISLC; Sept. 24-28, 2000; Monterey, CA), researchers from the University of Wisconsin (Madison, WI) described fabrication and testing of a two-dimensional phase-locked antiguided VCSEL array that emits a diffraction-limited beam. The 4 x 4 array reaches an optical power of 2 mW and is prevented from reaching higher powers only by limits to heat removal. Versions of the device have been built in which the adjacent elements are either in or out of phase. The in-phase version produces a strong central fundamental-mode beam, along with weaker outlying beams that are the unavoidable result of the emitter's periodic configuration (see figure). The central beam has an angular width of 2° full width at half-maximum (FWHM), while the side lobes are separated from the central beam by approximately 7°. The out-of phase version emits four beams in a square arrangement with a separation of 7°.

The devices are gallium arsenide based and emit at 980 nm. Each element is 6 x 6 µm in size and is apertured by a 5 x 5-µm window. The interelement region is adjusted in width to select either the in-phase (2.5-µm separation) or out-of-phase (3.0-µm separation) resonance. To produce an index step of 0.05 for antiguiding, the researchers etch away spacer layers under the emitting areas and then regrow the top distributed Bragg reflector, providing a shift in the optical resonant mode.

With better heat removal, 100-mW output should be easily achievable, says Luke Mawst, one of the researchers. One approach to better heat removal would be to mount the VCSELs junction-down on a diamond heat sink—a technique developed for single high-power VCSELs by a group at the University of Ulm (Ulm, Germany) and also presented at ISLC 2000. Mawst adds that power output of an antiguided VCSEL array could go much higher. The University of Wisconsin group has made a 40-element linear array that performed well, showing that a 40 x 40 array is possible. Such a device would only need to produce 1 mW per element to reach outputs in the watt range, notes Mawst.

The 980-nm wavelength is suitable for pumping erbium-doped fiber amplifiers, but the antiguiding technique can be implemented at other wavelengths as well. For example, low-power VCSELs emitting at 1.3 or 1.55 µm could be combined into a diffraction-limited VCSEL-based emitter equal in power to edge-emitting distributed-feedback telecommunications lasers, says Mawst.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.