MICROMACHINING: Excimer laser drills deep, clean holes

Laser-drilling of deep holes in inorganic materials has traditionally been done using 532-nm frequency-doubled or 355-nm frequency-tripled pulsed Nd:YAG lasers, which have achieved aspect ratios (the ratio of hole depth to diameter) of up to 200. However, absorption of the laser light by the plasma stream ejected from the hole can be a problem. Researchers at Laserzentrum FH Münster (Steinfurt, Germany) are solving this problem by replacing the source with a 248-nm-emitting krypton-fluoride excimer laser coupled with beam-homogenizing optics.

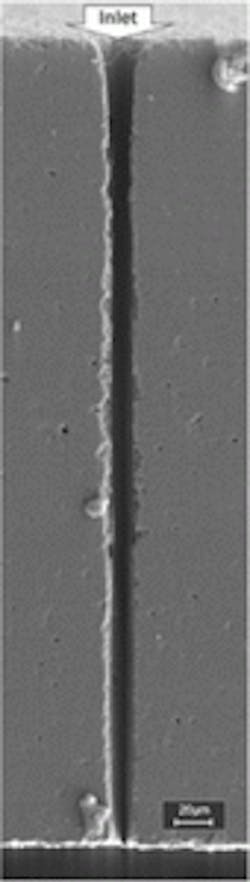

The system offers a fluence of 60 J/cm2 and already has been used to drill 10-µm-diameter holes in an alumina ceramic plate 0.5 mm thick (an aspect ratio of 50), as seen in the accompanying scanning electron micrograph. These holes were drilled using a mask-illumination technique in which the mask was demagnified by a factor of 15. The holes took 2240 pulses to complete at a 100-Hz repetition rate.

The secret is the shorter wavelength. "With increasing depth and decreasing hole diameter, the plasma has to overcome more and more resistance to escape out of the hole during laser drilling," explains Klaus Dickmann, one of the researchers. "The plasma, streaming with high velocity out of the hole toward the incident laser beam, increases in density. As a result, the absorption of the incoming laser beam by plasma also increases. To overcome this, the wavelength of laser radiation can be reduced. The excimer laser wavelength is shorter than the frequency-doubled and tripled Nd:YAG wavelengths."

The holes show virtually parallel walls. The interaction process that causes this is called the keyhole effect, in which the laser radiation is guided down to the bottom of the hole by multiple grazing-incidence reflections off the wall. The effect is strengthened when the pulse duration and wavelength are decreased and the beam intensity increased. The beam-homogenizing optics are an important part of the package, for they are what ensure that all holes are drilled to the same depth and diameter.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.