LIGHT-EMITTING SOURCES: EL component formed directly on printed-circuit board

Incorporating news from O plus E magazine, Tokyo

KAWASAKINippon Membrane Co. and Shinwa Inc. have jointly developed an electroluminescent (EL) component that can be created directly on a printed-circuit board. Conventional light-emitting componentsfor example, light-emitting diodes (LEDs)use transparent conduction films such as indium tin oxide (ITO) as one electrode.

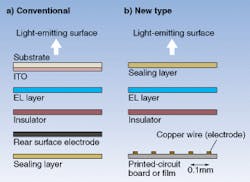

Conventional light sources such as LEDs rely on one electrode made of ITO (left); a new source places electrodes directly on the electronics, allowing greater flexibility in light patterns and potential applications in simple displays and toys (right).

In the new approach, line-shaped electrodes of alternating polarity are placed close together on the board, rendering a transparent conduction film unnecessary (see figure). The manufacturing process is simpler and the light emission pattern can be made in versatile shapes.

The new source can be made to display information such as numbers and can be used in glowing logos, backlights, and game displays. The companies say this technology can be developed further for use in more-sophisticated displays containing many pixels.

The source operates with an input voltage above 5 V and can achieve a luminance greater than 70 cd/m2. The energy required for this performance is approximately one third to one half that required by an LED of similar luminanceand without the production of significant heat.

Courtesy O plus E magazine, Tokyo