DIODE-PUMPED SOLID-STATE LASERS: Edge pumping drives slab-laser performance

Todd S. Rutherford, William M. Tulloch, and Robert L. Byer

Diode-pumped solid-state lasers are rapidly gaining acceptance in applications such as materials processing, medicine, metrology, and remote sensing. Reasons include their high efficiency, diffraction-limited beam quality, and long lifetimes. Compact rugged packages and low maintenance requirements also make them attractive laser sources from an operational point of view. Combined with nonlinear frequency conversion, the lasers can span the spectrum from the UV to the mid-IR and operate in a wide range of pulse formats from subpicosecond to continuous-wave (CW).

To date, the cost of laser diodes has prevented diode-pumped solid-state lasers from competing with CO2 gas lasers or flashlamp-pumped systems in applications that require high average powers. Laser diode prices, though, have been dropping about 30% per year, and by some predictions, their cost will be below one dollar per watt in 2004.1 Even with this trend, current commercial diode-pumped rod designs cannot directly scale much further in average power. An alternative design using edge-pumping of a zig-zag slab gain medium offers a solution.

Zig-zag slab laser solutions

Most diode-pumped solid-state lasers are based on a rod-type geometry, with the laser medium in the shape of a cylinder. This geometry, which dates back to the first demonstrated laser, is effective at moderate output powers (tens of watts of average power). As the power increases, though, several problems arise. Thermal lensing caused by radial temperature dependence in the rod can destabilize the laser cavity. Even more insidious is the effect of stress-induced birefringence, which causes a nonuniform depolarization loss that disrupts the spatial mode and lowers the efficiency. Both effects can be mitigated with careful resonator design, use of birefringent host materials, composite crystals, and even phase conjugation. Eventually though, the rod geometry reaches an average power limit.

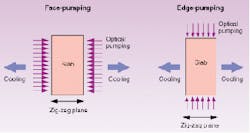

A solution to these problems has been known for almost 20 years.2 With this design, the laser beam basically bounces between the two large faces of the slab using total internal reflection (see Fig. 1). Only the faces are cooled, so the temperature gradient is forced to be nearly one-dimensional. Thermal lensing is reduced because the zig-zag optical path averages the optical distortions caused by the one-dimensional thermal gradient. The rectilinear cross section solves the problem of stress-induced birefringence.Despite these advantages, zig-zag slab lasers have been slow to reach commercial acceptance. The reasons commonly cited include complex design, low efficiency, and high cost. The traditional design requires the pump light to enter the slab through the large faces. As a result, this interface requires good thermal conductivity. It also should be transparent to the pump light and maintain the total internal reflection for the laser light. This is usually accomplished by flowing water directly over the faces, necessitating seals between the mechanical mounting structure and the slab and making the system sensitive to contamination. Also, the water flow causes slab vibrations, which in turn magnify the multiple total-internal-reflection bounces and cause beam-pointing jitter. As a further complication, the pumping efficiency is reduced due to the many surfaces between the laser diodes and the gain medium.

Moving the pump source to the slab edge faces solves these problems. This design separates the pumped and cooled surfaces and simplifies the design.3 Fluid seals are not needed because direct conduction cooling to an opaque heat sink is now possible. Because no fluid flows on any optical surfaces, there is no contamination and system reliability improves.

Edge pumping also increases the efficiency. The pump light couples directly into the laser medium and has a long path length along the slab width. The direct coupling eliminates losses from surface reflections and scatter in the turbulent fluid. Slab lasers typically have a width that is several times the thickness to improve the cooling. Pumping from the edge allows the pump light to be absorbed along this width dimension, increasing the absorption depth significantly. More pump light reaches the slab, and more of the light reaching the slab is absorbed.

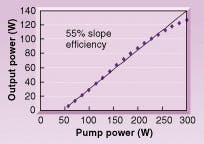

The edge-pumped zig-zag slab concept has been demonstrated at Stanford University with a Nd:YAG gain medium (see photo at top of this page). The testbed laser has yielded 127 W of multimode output power for 300 W of pump power. The resulting 42% optical-to-optical efficiency means that about 90% of the pump light is absorbed in the active medium.

In the system, the laser head is quite simple. The slab is clamped between two copper blocks that provide both conduction cooling and a solid mechanical contact. Optical fibers deliver the pump light from remotely located laser diodes. The heat load from the laser diodes is thus dealt with separately from the heat produced in the laser head. As a result, the laser head is compact, on the order of 350 cm3. In more than a year of use, the head has required no maintenance and has not degraded or failed. Its small size also means that it can fit easily on the end of a robot arm or positioner for materials-processing applications.

Edge-pumping leads to improved efficiency and simplicity in four-level lasers, but it provides a critical advantage for operating quasi-three-level media such as Yb:YAG in a slab configuration.4 Quasi-three-level lasers are attractive because of a higher potential efficiency and lower thermal distortion per unit power than four-level lasers such as Nd:YAG. Quasi-three-level lasers, however, have a residual population in the lower laser level due to thermal excitation. To achieve gain at the lasing wavelength, the lower-level population must be overcome. This places two strict design requirements on these lasers—high pump brightness and good cooling.

The edge-pumped slab maintains pump brightness by total internal reflection of the pump light over the entire width of the slab. For slabs with a large aspect ratio (width/thickness), the doping can be low because the absorption path length is long and the cooling through the large total-internal-reflection faces is efficient. This makes the transparency point of the quasi-three-level system easy to reach (see Fig. 2).Pump-power business

When comparing various configurations for high-power operation of Yb:YAG, the figure of merit is the pump power at which the active medium fails due to stress fracture divided by the pump power required to drive the medium to transparency. This parameter is lower at higher temperatures because of the increased thermal population in the lower laser level. Large values indicate the ability to operate the laser well above threshold without concern for catastrophic failure of the material. Operation far above threshold is important for high efficiency. The edge-pumped slab can compete with the thin-disk design for quasi-three-level lasers and has advantages over rods and face-pumped slabs.5,6

As applications continue to push diode-pumped solid-state lasers to higher average powers, rod lasers become increasingly difficult to engineer. The potential benefits of the zig-zag slab laser have been understood for decades. Edge-pumping finally offers a simple slab design that is capable of high efficiency, good beam quality, and reliable operation in a power-scalable architecture. In addition, edge-pumping promises efficient operation of quasi-three-level lasers such as Yb:YAG.

REFERENCES

- Donald Scifres, Plenary Talk, CLEO '99 (Baltimore, MD).

- W. S. Martin and J. P. Chernoch, "Multiple internal reflection face-pumped laser," US Patent 3633126 (1972).

- W. M. Tulloch, OSA Trends in Optics and Photonics 26, 9, OSA (1999).

- T. S. Rutherford et al., "Edge-pumped quasi-three-level slab lasers," J. Quant. Electron. (Feb. 2000).

- S. Erhard et al., OSA Trends in Optics and Photonics 26, 38, OSA (1999).

- D. S. Sumida et al., Solid State Lasers vII 3265, 100, SPIE (1998).

TODD S. RUTHERFORD and WILLIAM M. TULLOCH are Ph.D. students and ROBERT L. BYER is director of the Center for Nonlinear Optical Materials at Stanford University, Stanford, CA 94305; e-mail: [email protected].