Optoelectronic Applications: Projection Displays: Laser-based projectors target consumer market

For consumers, it’s all about the “viewing experience.” For consumer electronics companies, it’s all about the cost. Currently, the market for laser-based projection displays—that is, rear-projection televisions (RPTVs), front-projection systems, and pocket projectors—is caught between a technology that offers superior image quality and a price tag that makes it a hard sell.

At the heart of this dilemma is the laser. Today’s compact solid-state lasers enable the image brightness, greater color gamut, and resolution that make for great viewing, with the added bonus of longer lifetimes than lamp-based light sources (see Fig. 1). But these lasers cost a lot more than the ultra-high-pressure (UHP) arc lamps they are trying to displace. For example, the light sources used in RPTV systems require 300 to 600 lumens of brightness and 3 to 5 W of power per laser, at a total cost of less than $100 for all three lasers. But solid-state lasers sell for much more than that.

“All the big consumer electronics companies know the value of lasers, but no one currently has the lasers at the (right) price point,” said C. J. Johnson, business segment manager for the display and components group at Eastman Kodak (Rochester, NY). “You can’t put a RPTV out there at $10,000 and have it compete with a $2000 nonlaser system.”

Magnifying the image

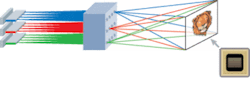

There are basically two types of RPTVs: traditional cathode-ray tube (CRT) displays, in which three separate CRTs (red, green, and blue) project light through a lens onto the screen; and microdisplay-based systems, in which a small version of the image is first created on an LCD, DMD/DLP, or LCOS microdisplay and then projected onto the larger screen. In a conventional microdisplay, the light source is a UHP white-light lamp that must work in conjunction with a color filter and optical train to achieve the desired RGB spectrum. In a laser projector, the light engine is a combination of three solid-state laser sources—620 to 630 nm (red), 532 nm (green) and 460 nm (blue)—that works directly with the microdisplay to eliminate the need for a color filter.

A key component of the microdisplay is the digital light processor (DLP), based upon the digital micromirror device (DMD) developed by Texas Instruments in the 1980s. It helped change the perception of RPTVs from the dim, refrigerator-size boxes of old to the high-quality RPTVs seen in stores today. The DMD is an array of digital micromirrors, monolithically integrated onto, and controlled by, a memory chip. Digital light-processing systems based on the DMD yield bright images with high fidelity and stability. The first DLP-based projection displays (lamp-based) were introduced to the market in 1996. A fundamental advantage of the technology is that, unlike liquid-crystal display (LCD) technology—in which light must pass through a polarizer screen—the mirrors create images by reflecting light, resulting in a brighter image. In addition, because of cost and design complexities, there has been a shift away from LCD and liquid-crystal-on-silicon (LCOS) microdisplays.1

Other platforms designed to enhance the modulation of light in projection displays include the GLV (grating light valve) from Sony/Silicon Light Machines and GEMS (grating electromechanical system) from Kodak. In essence, GEMS and GLV are diffractive-MEMS spatial light modulators that contain a linear array of pixels capable of high-speed operation, high optical contrast, and good efficiency (see “Laser light shows take on new dimensions,” Laser Focus World, November 2004). According to Johnson, GEMS differs from DLP in that it does not require a full array of pixels. Rather, two-dimensional images are created by using a spinning galvanometer to sweep a 1080-pixel line image of the array across the display screen and bouncing it off the mirrors. The GEMS device can switch in 30 to 50 ns, enabling an HDTV (1080 × 1920 pixels) image to be generated from a single line of 1080 pixels and fundamentally providing a lower-cost modulator than a full-area array, plus greater native bit depth.

The laser’s the thing

Currently, the biggest potential market for laser-based projection systems is RPTV. But the general consensus is that affordable laser-based RPTVs are two to three years away from commercial reality. In the meantime, those companies building solid-state lasers for this application are under the gun to make them more affordable and easier to manufacture in large volumes.

“The beauty of the display is that it is very forgiving in terms of laser parameters,” said Colin Seaton, director of business development in the advanced research division at Coherent (Santa Clara, CA). “People (in the display industry) don’t really care about beam quality or noise; if the laser has 10% noise on it, the eye isn’t even going to see it. So you can design the laser to be only as good as it has to be because at this point, for this application, it is all about manufacturability.”

Surprisingly—at least from a laser perspective, where the emphasis of late has been on compact blue and green devices—red is the most critical of the three colors in a projection display. According to Seaton, in addition to 530 and 460 nm, a laser projector needs 635 nm to give the viewer the widest color gamut. If the red moves out even slightly to 640, the power needs increase.

“The green and blue are very straightforward, but the red is tricky because of the photopic response of the eye,” said Greg Niven, vice president of marketing at Novalux (Sunnyvale, CA). “The eye is not very sensitive to variations in blue and green, but a 10-nm shift in red from 635 to 645 requires twice the power for your eye to perceive the same brightness.”

But what is really driving this application is the development of compact blue and green solid-state technology. Coherent has focused its efforts on optically pumped semiconductor (OPS) lasers and has demonstrated a compact RGB source for projection displays based on the OPS technology for 460-nm blue and 530‑nm green and a 638-nm red diode laser, each yielding more than 4 W—sufficient to illuminate a large RPTV screen (see Fig. 2).2 According to Coherent, the R&D that has gone into this system has resulted in next-generation solid-state laser technology that should be applicable to a number of applications, including displays.“What we have done in the last year is show form, fit, and function with our OPS technology,” Seaton said. “People are now seeing that you can build something to size, that it can go into a TV set, and that it can replace lamps, and with a much brighter picture. The million-dollar question is can it be done at a cost point that can move it into consumer electronics for projection TVs that are at least 50 inches.”

Novalux is targeting projection displays as the primary market for its NECSEL lasers, which the company says are capable of cost-effective volume production by virtue of their design (see “NECSEL technology unveiled at OFC,” Laser Focus World, May 2001). Novalux has already demonstrated low power 460-, 488, and 532-nm output of the NECSEL via its Protera product, and more recently achieved more than 1 W at 532 nm from a NECSEL package smaller than a matchbox (see Fig. 3). The company says it is now working with several potential partners in consumer electronics and plans to demo a NECSEL-based RPTV at the Consumer Electronics show in January 2006.“Without the laser, the RPTV is a dying breed,” Niven said. “But if you look at what the laser has to do and what it has to be (in projection displays), the reality is any laser will work, but how much does it cost? The NECSEL is designed toward volume production because it uses wafer-scale components. It allows power scalability without laser redesign because you have an array of 100-mW beams, and all you have to do to scale up the device is add emitters. And because we are doubling infrared diode lasers, the NECSEL allows us to do RGB, or any wavelength, with the same technology, same production techniques, and same supply chain.”

Quintessence Photonics (Sylmar, CA) is another laser company with an eye on consumer electronics. Leveraging single-mode diode-laser technology originally developed for telecom, the company has achieved 3 W of single transverse mode per emitter and demonstrated this on a 40-W bar that has 12 emitters.3

“We are pushing the limits of high-power single-mode diode lasers,” said Paul Rudy, vice president of marketing and sales at Quintessence. “We are getting a lot of interest from people who are using diodes as an engine and doubling them for, say, projectors, TVs, and even microdisplays.”

Other alternatives

Light-emitting diodes are also emerging as an alternative light source for projection displays, in large part because of their lower cost. Lumileds (San Jose, CA) is involved in a project with the U.S. Display Consortium to create a compact LED illuminator for this application (see “Lumileds to develop LEDs for projection displays,” Laser Focus World web news, June 22, 2004); similarly, Osram Opto Semiconductors (Regensburg, Germany) has introduced the Ostar platform, which combines four to eight thin-film LEDs (InGaAlP for red and amber, ThinGaN for blue and green) in a package the size of a PDA to achieve 15 to 20 lumens of projected RGB light.4

But in their current iteration, LEDs are not powerful enough for use in front- or rear-projection displays. They are, however, well-suited to the new “pocket projectors” just coming to market, according to Wolfgang Lex, marketing director for visible LEDs at Osram. Osram believes the brightness, uniform light, and small mounting depth of the Ostar make it ideal for use in miniprojectors and, other applications, including head-up displays and forward lighting for cars. In the meantime, the company is working to optimize the primary optics to enable collection of all photons coming out of the chips and thus improve output efficiencies.

“We believe there is room for both lasers and LEDs in this market, and we have both technologies under development,” Lex said. “We expect to introduce an LED-based mobile projector in the United States by Christmas.”

REFERENCES

1. P. Putnam, “Are microdisplay rear-projection TVs on the way out?” HDTVexpert, Aug. 24, 2005.

2. J.L.A. Chilla et al., LASE 2005, invited paper.

3. R.M. Lammert et al., SPIE 2005 Annual Meeting, invited paper.

4. M.H. Keuper, G. Harbers, S. Paolini, SID 04 Digest, 943.

Kathy Kincade | Contributing Editor

Kathy Kincade is the founding editor of BioOptics World and a veteran reporter on optical technologies for biomedicine. She also served as the editor-in-chief of DrBicuspid.com, a web portal for dental professionals.