VERY HIGH-PEAK-POWER LASERS: Cryogenic cooling multiplies output of Ti:sapphire laser

DIRK MÜLLER, STERLING BACKUS, KENDALL READ, MARGARET MURNANE, and HENRY KAPTEYN

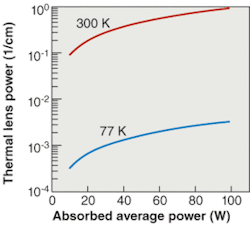

The broad laser bandwidth and excellent material properties of titanium-doped sapphire (Ti:sapphire) have proved ideal for small- and large-scale ultrafast lasers and systems.1 Incorporating cryogenic cooling into an ultrafast Ti:sapphire laser amplifier can reduce thermal-lens-induced aberrations by more than two orders of magnitude, resulting in additional performance improvements. Although not common in lasers, cryogenic cooling makes ultrafast systems more versatile and is also surprisingly cost-effective for a variety of applications (see Fig. 1).

Ti:sapphire amplifier systems are typically pumped by frequency-doubled Nd:YAG or Nd:YLF lasers, and very high-average-power lasers of this type (approximately 100 W) have existed for some time. Previous-generation Ti:sapphire systems were incapable of using these pump lasers fully, however, because of thermal-load limitations. In a Ti:sapphire laser amplifier, light from the pump laser is focused on the Ti:sapphire rod, and during amplification a photon at approximately 532 nm, (2.33 eV) is absorbed by the Ti:sapphire and emitted as a photon at approximately 800 nm (1.55 eV). The rest of the energy-roughly one-third of the incident power-is converted into heat. With a 100-W pump laser focused into a submillimeter spot, the heat load creates very strong temperature gradients that distort the optical properties of the crystal, producing distortion of the amplified pulse. The distortion results from the changing index of refraction of the sapphire with temperature, and the physical expansion of the material, which causes a bowing of the output faces.

To a first approximation, the thermal loading corresponds to a variable-focal-length lens in the optical system. Proper amplifier design can compensate for this lens to some extent, but large optical aberrations remain. Hence, early-generation Ti:sapphire systems were limited to about 1 W before thermal distortion became a serious problem. Potential applications were also limited because thermal lensing limits the pulse repetition rate.

Many processes that were demonstrated first using low-repetition-rate systems-such as ultrafast micromachining, coherent x‑ray generation using high-order harmonics, or high-energy particle generation-would become much more useful as tools for research or industry if the repetition rate could be increased. Furthermore, state-of-the-art basic science experiments require very high signal-to-noise ratios to find small signals buried in large backgrounds. Higher repetition rates would allow higher signal-to-noise ratios.

Benefits of cryogenic cooling

The obvious solution to the thermal-lensing problem would be to find a better gain material, but Ti:sapphire is tough to beat. Sapphire is second only to diamond as a thermally conductive transparent material. And Ti:sapphire has a broader bandwidth than any other gain material-ideal for ultrafast applications. So Ti:sapphire will likely be the material of choice for high-performance ultrafast lasers for some time to come. Among numerous techniques proposed to address thermal lensing, the most obvious has been to compensate with corrective optics. This approach can improve the situation, but it also makes the system ultrasensitive to pump-power fluctuations. Furthermore, it is not possible to compensate for higher-order thermal-lens aberrations.

A very effective solution, although less familiar to laser users, is to aggressively cool the laser crystal. It has been known for some time that cryogenic cooling of Ti:sapphire improves its characteristics, but our group was the first to implement it in ultrafast systems during the late 1990s. We first used cryogenic cooling for the “power amplifier” after the preamplifier in an ultrafast system. Later we realized that the realbenefit of cryocooling is its use in the regenerative or multipass amplifier itself, because this is the place where most of the gain in a system occurs and where optical aberrations accumulate. Cryocooling technology thus proved to be much more useful than originally anticipated, and was also patented.2

The advantage of cryocooling is significant and the technology for implementing it is simple, reliable, and cost-effective. Cooling a Ti:sapphire crystal to between 50 K and 80 K results in a greater than 200× decrease in thermally induced distortions in the beam being amplified (see Fig. 2).There are two reasons for this dramatic improvement. First, the thermal conductivity of sapphire increases by a factor of roughly 39 when the temperature is decreased from 300 K to 77 K. Second, the change in index of refraction with temperature decreases by a factor of 7.3. These factors are multiplicative.

The dramatic reduction in lensing simplifies the amplifier configuration, because the amplifier will now act as a nearly ideal gain medium, with very little optical aberration even for very high pump power. This makes it possible to take advantage of very high-average-power 532-nm Q-switched pump lasers-at least four different manufacturers make lasers in the range of 100-W output, in diode-pumped or cost-effective lamp-pumped models. The greater pump power can allow for either increased energy per pulse, or increased repetition rate, depending on the pump laser.

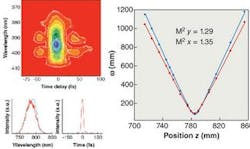

Another major benefit is an increase in the pump-to-output optical conversion efficiency-up to 25% to 30%-before pulse compression losses. The improvement occurs even for cryogenically cooled systems that use relatively modest (about 25 W) pump lasers and makes cryogenic technology much more cost-effective than originally anticipated. The result is a “no compromise” Ti:sapphire laser system that can generate pulses as short as 20 to 30 fs, with near-diffraction-limited focusability, and with significantly more output power. The improved performance far outweighs the moderate increase in cost.Implementation

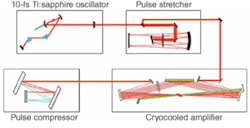

Cryocooling technology has been implemented in our Dragon ultrafast amplifier system, which was first introduced in 2002, and has since been used with a large variety of diode-pumped and lamp-pumped pump lasers (see Fig. 3). We have implemented one-stage and two-stage systems, the latter for high-single-pulse-energy applications. The single-stage system can be pumped at up to 20-kHz repetition rate, and can deliver an average power of up to 10 W (see Fig. 4).3 The uncompressed output power of 16 W results in a 20- to 30-fs compressed output power of more than 10 W, with a pulse energy of more than 10 mJ at 1‑kHz repetition rate.The limits of cryogenically cooled amplifier technology are essentially the average power limits of the pump lasers. The theoretical fracture limit-a power level at which the crystal sustains physical damage-for end pumping of Ti:sapphire is about 1.2 kW per face, meaning that it should be feasible to construct kilowatt-scale ultrafast lasers in the future.4 In the lab, diode-pumped 532-nm laser modules have been demonstrated at powers of up to 300 W in a very compact form factor.5 As new-generation pump lasers are introduced, ultrafast table-top amplifier systems can be straightforwardly developed with output powers of tens to hundreds of watts, at only modest increase in cost.

One critical area that requires improvement is in the pulse compression process. At high average powers, the pulse compression gratings show thermal distortion. Creative approaches can likely get around this problem, however. One approach would be to use nonabsorptive dielectric compression gratings; another would be a concept we recently demonstrated called downchirped pulse amplification (DPA), which turns the conventional CPA process on its head. In DPA the pulse stretcher generates a negatively chirped pulse rather than a positively chirped one.6 The pulse is then amplified, and recompressed using positive material dispersion from a block of glass, which does not absorb any light or experience thermal distortions.❏

REFERENCES

1. S. Backus, C. Durfee, M. M. Murnane, H. C. Kapteyn, Rev. Scientific Instruments69, 1207 (1998).

2. S. J. Backus, H. C. Kapteyn, M. M. Murnane. (Regents of the University of Colorado, U.S. Patent 6,804,287, 2004).

3. S. Backuset al., Optics Lett.26, 465 (2001).

4. W. Koechner, Solid-State Laser Engineering (Springer-Verlag, Heidelberg, 1996)

5. J. Chang et al., Science and Technology Rev., (www.llnl.gov/str/Chang.html; October 1999).

6. D. M. Gaudiosi et al., Optics Lett.29, 2665 (2004).

DIRK MÜLLER is product line manager, STERLING BACKUS is CTO, KENDALL READ is COO, MARGARET MURNANE is president and CEO and HENRY KAPTEYN vice president at Kapteyn-Murnane Laboratories, 1855 South 57th Court, Boulder CO 80301; e-mail: [email protected]; www.kmlabs.com.