Ultrafast Lasers: Chromatic-dispersion tuning enables efficient manufacturing of CPA femtosecond lasers

RENÉ DIONNE

Because of their distinctive capabilities, ultrafast lasers are unique tools for modern materials processing. The ability they have to process almost any material without heating it allows for high-accuracy, high-aspect-ratio machining, making them strong assets in the manufacturing of valuable components.

To sustain and accelerate market adoption of ultrafast lasers, shorter development time and cost-effective designs are crucial. In an ideal world, these lasers would deliver high performance while being versatile and compact. However, manufacturers are facing many challenges with the design and manufacturing of ultrafast lasers. With the wide range of components available, lasers can be built following several different architectures. When designing a laser, not only the perfect balance between all these parameters must be found, but it must also be aligned with the end-application requirements. Moreover, maintaining a steady assembly performance in manufacturing is critical for mass deployment, especially for high-energy femtosecond lasers.

Although mode-locked oscillators are capable of creating ultrashort pulses, the resulting energies generally limit their use to applications such as spectroscopy and imaging. For applications requiring more energy (for example, micromachining), the pulses must be amplified. However, ultrashort-pulse amplification is challenging because even low-energy pulses exhibit sufficient peak power to induce undesired nonlinear effects in the amplification stage and can even damage the amplifier.

To protect the amplifier and maintain a good pulse quality, the chirped pulse amplification (CPA) technique can be used. The seed pulse is temporally stretched before the amplification stage to reduce its peak power. After amplification, the pulse is then recompressed as close as possible to its transform-limited pulse duration. The architecture of a typical CPA laser can be divided into a few individual building blocks (see Fig. 1):

- A mode-locked laser that generates short pulses at high repetition rate

- A pulse picker that reduces the repetition rate and manages burst modes, according to the specific application requirements

- A pulse stretcher that decreases the peak power before the amplification stages

- A pulse compressor that recompresses the pulse after amplification

- Several amplification stages, which amplify the seed pulses by up to six orders of magnitude

- An optional frequency converter that converts the infrared (IR) light from the CPA into visible or UV light for improved absorption or spatial accuracy

- Delivery optics and scanners that bring the pulses to the workpiece

CPA laser components

The remainder of this article will focus on the CPA portion of the laser: pulse stretchers, amplifiers, and pulse compressors.

Pulse stretchers and compressors. Different technologies and components can be used as dispersive elements for either stretching or compressing the pulse. While bulk optics components such as chirped volume Bragg gratings (CVBGs) and diffraction gratings can be used for either stretching or compressing, their high power-handling ability makes them assets as compressors. Because of cost and space constraints, fiber and chirped fiber Bragg gratings (CFBGs) are the common choices for stretchers.

Fiber. The intrinsic chromatic dispersion of optical fibers naturally disperses the spectral content of a pulse. Because of their low chromatic dispersion, fiber has a limited stretching capability.

Chirped fiber Bragg gratings. Chirped fiber Bragg gratings are made by inducing periodic refractive index changes in the core of optical fibers, with a period that varies along the length of the grating. The resulting grating reflects the pulse over a certain length of fiber. This induces a wavelength-dependent group delay, which allows for the temporal stretching of the pulse. CFBGs can be customized to match the expected chromatic dispersion of a complete system. The total stretching provided by commercially available CFBGs can reach more than one nanosecond.

Chirped volume Bragg gratings. Similar to CFBGs, chirped volume Bragg gratings (CVBGs) are Bragg gratings that are inscribed in the volume of a transparent material, with a longitudinal variation of the Bragg wavelength. A wavelength-dependent group delay is then induced when the pulse is reflected in the CVBG structure. The stretching and compression provided by commercially available CVBGs can reach a few hundreds of picoseconds.

Diffraction gratings. Diffraction gratings are used to angularly disperse the different wavelengths of a light beam, creating light paths that vary according to their wavelengths. A variable delay is then created along the pulse spectrum, temporally stretching or compressing the pulse going through this optical assembly. The compression provided by commercially available diffraction gratings is customizable from tens of picoseconds up to a few nanoseconds.

Amplifiers. There is a wide range of technologies available for amplification and many combinations of these technologies are possible. Fiber amplifiers are the preferred choice for the first few stages of amplification because of their robustness and cost-effectiveness. Large-mode-area (LMA) fiber, rod-type, disk, and slab amplifiers compete for the final amplification stages. All these possibilities have an impact on the overall chromatic dispersion and nonlinearities of the system.

Manufacturing challenges

Femtosecond lasers are valued for their high peak power. Pulse quality is crucial, as any distortion in the pulse results in decreased peak power, affecting the overall process efficiency.

One of the challenges of industrial manufacturing of femtosecond lasers is to maintain a constant pulse quality for every laser produced. Femtosecond lasers are built using a large variety of components, all having their own specifications and tolerances. The addition of these tolerances along the optical path can make up for significant variations in total chromatic dispersion, affecting the output pulse quality. Additionally, variations in the manufacturing process, such as fiber splicing, compressor alignment, and nonlinearity mitigation, will also affect the overall chromatic dispersion of the system.

To compensate for these disparities, laser manufacturers will require tighter specifications from their component suppliers. This mitigation method has its limits and can prove costly in the long term. Manufacturers will also tighten the whole manufacturing process, increasing the manufacturing time and decreasing the yield, which results again in an increased total cost.

Benefits of tunable pulse stretchers

Instead, these variations can be efficiently compensated at the pulse-stretching level. As discussed previously, CFBGs are customizable and can be tailored to match the expected total chromatic dispersion of the system. Moreover, the CFBGs can be integrated in a tunable platform to make them tunable pulse stretchers.

The adjustable chromatic dispersion provided by these tunable pulse stretchers then becomes an asset for the manufacturing of commercial lasers. CFBG-based tunable pulse stretchers can apply correction to the group delay up to the fourth order, which compensates for linear variations in group delay, as well as most pulse-energy-dependent delay variations caused by nonlinear effects, such as self-phase modulation. This feature greatly simplifies the use of both bulk-grating-based and VBG-based compressors, where tuning is cumbersome and impractical.

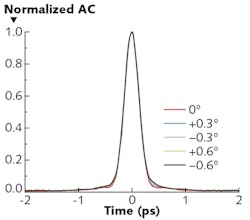

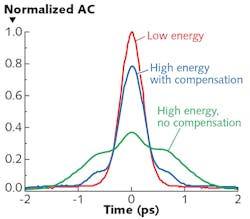

For example, a small change of a fraction of a degree in the grating angle of a typical Treacy compressor (a pair of gratings) may substantially reduce the peak intensity of the compressed pulse by increasing its duration. A similar behavior can occur when the distance between the compressor gratings deviates from its optimal value. This former case is shown in Figure 2, where a compressed 300 fs pulse is optimised using a CFBG-based tunable stretcher to compensate a grating angle deviation of up to ±0.6°. Without compensation, the pulse duration would reach about 30 ps under the maximum angle deviation. This experimental result clearly shows that the tunable pulse stretcher can easily cope with the temporal impact from grating-compressor misalignments, maintaining the optimal peak power.Another interesting feature of the tunable pulse stretcher is highlighted when the pulse energy is increased. In this situation, self-phase modulation occurs and distorts the pulse. Figure 3 shows how the distortion created by self-phase modulation significantly reduces its peak power (green curve). The CFBG-based tunable pulse stretcher can considerably improve the pulse quality by applying a nonlinear group delay correction, compensating most of the nonlinear effects that correspond to a B-integral (accumulated nonlinear phase shift) of about 4 in this specific situation. The resulting pulse (in blue) is much closer to its transform-limited shape. The tunable pulse stretcher therefore allows working at different energy regimes using the same laser design and components.

This ability to compensate for many different variations in the manufacturing process makes the tunable pulse stretcher a simple and effective solution to reduce the pressure on components and manufacturing process tolerance. This could result in faster product development time, simplified bill of material, increased production yields, and reduced manufacturing costs. It should also contribute to reduce lead times and acquisition cost, hopefully further accelerating market adoption of high-energy femtosecond lasers.

René Dionne is product line manager at TeraXion, Québec City, QC, Canada; e-mail: [email protected]; www.teraxion.com.