CHRISTOPHER J. DYBALL and TERRI LICHTENSTEIN

Optical discs are familiar objects while optical cards are much less well-known. Optical cards offer many of the recording capabilities of the disc format plus several significant and unique features. The shape and flexibility of the cards are similar to credit cards (see Fig. 1). Optical cards offer a durable platform, which, unlike an optical disc, can be conveniently carried in a wallet and can carry secure, unalterable digital data that can include images as well as text. Unlike the spinning disc, the optical card uses a rectilinear format in which the tracks are arrayed rather like the lines on a ruled sheet of paper with each track being numbered (see Fig. 2).To read data from the card, a shuttle moves the card along the track direction at a rate of 1 m/s in a bidirectional fashion. The format permits true random access. Track-to-track translations are achieved by movement of the optical head in the cross-track direction with seek times as fast as 2 ms.

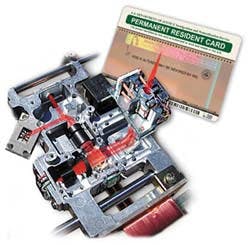

Optical cards find use in many portable data storage applications with the largest usage being secure personal identification (ID) cards—for example, the US Permanent Resident Card ("green card") and the Italian national ID card.

While conforming to ISO standards for identification cards, optical memory cards offer a user data capacity of 2.9 Mbytes, which is much higher than that available on magnetic stripe cards (270 bytes) or smart cards (up to 16 kbytes). To remain compatible with existing infrastructures and for increased versatility in many applications, the optical card can also include a magnetic stripe or integrated circuit chip.

Optical memory card media

The recording media used in the optical card is based on silver halide photographic film. Formatting of the media is achieved by photographic processes prior to the encapsulation of the media into cards. The photographic formatting process also allows for the creation of other visible high-resolution (12,000 dpi) images in the media, which cannot be replicated by printing processes. The finished optical media is of the write-once-read-many type (WORM; see Fig. 3).On top of the card substrate are three layers: an encapsulation layer, a crust, and an underlayer. The encapsulation layer is a 380-µm laminated polycarbonate film. The crust consists of silver grains of filamentary and spherical shapes dispersed in an organic colloid. The underlayer consists of the same organic colloid but is essentially devoid of silver particles. The underlayer thermally insulates the reflective crust and increases the laser recording sensitivity. Data bits are recorded with a 780-nm semiconductor laser which causes agglomeration of the silver particles reducing their covering power and hence the reflectivity of the media. Secondarily, thermal deformation of the colloidal binder results in the formation of a pit.

The laser-recorded pits are 2.5 µm in diameter. While this is large compared to bit sizes used on optical discs, the card is intended to withstand rugged use, such as being carried in a wallet for a period of years. In such applications, the larger bit size and the 12-µm track-pitch confer a degree of robustness that could not be achieved with the geometries normally used on optical discs. To further enhance reliability, a pulse-position-modulation (PPM) recording scheme is utilized rather than the pulse-width-modulation (PWM) scheme often used on optical discs. Because optical cards may be carried in a wide range of environmental conditions, the PPM recording scheme renders the card less vulnerable to media sensitivity changes or changes in laser output brought about by exposure of the card or read/write drive to environmental extremes.

The optical-card drive

The drive is supplied as a peripheral to a personal computer, connected via a SCSI card (see table). To the user, the use of the optical-card drive is no different from that of a CD-R drive.Once again, the optical-card drive design differs from a typical optical disc system in that the card is designed for maximum durability when carried by the holder. To this end, the drive incorporates a more powerful error-correction code than the Reed-Solomon codes normally used for optical discs. The burst error for satellite transmission (BEST) code used on optical cards requires a significant overhead,1 so that the 4.1 Mbyte raw data capacity of the card is reduced to 2.9 Mbyte user data capacity. This enables data to be read from cards that have been damaged from long use.

The fact that each track on the card is numbered opens up possibilities for novel security measures. For added security in a given application, a unique track numbering scheme different from that specified in the ISO standard can be created. The firmware of the drive is then modified to allow access to the non-standard tracks for writing to and reading from the card. Thus, the card/drive combination can be specific to the application. The card-issuing authority controls the drives used in its particular application. A forger cannot use a standard drive to attempt to make fraudulent cards.

This control measure is inexpensive, requiring only the creation of a master tool for the unique track numbering of the card and a custom firmware chip for the drive. As an added safety measure, the custom firmware chip can be locked by a serial number to a given drive. If the chip is removed from a drive and substituted into a different drive, it will not operate. Most government applications use some version of the unique track numbering scheme to forestall attempts to make fraudulent cards, as well as to prevent unauthorized access to the data on a genuine card.

Drives can be built as read only or read/write to meet the requirements of the application. For example, applications may use drives capable of writing at a card-issuing location, whereas the drives in use for card verification in the field are read only.

Optical card applications

While optical cards are used in a wide range of portable data storage applications, the largest usage is for secure identification. This application makes full use of the ability to create visible high-resolution images and watermarks in the optical media at resolutions up to 12,000 dpi, thereby preventing fraudulent duplication of the card by printing or copying techniques. The large data-storage capacity of an optical card, compared to other card technologies, allows for recording of multiple identification features such as photographs, fingerprints, and signatures.

In addition, it is possible to create a laser-etched visibly recognizable graphic in the media itself, irreversibly marking the memory with the identity card holder—a unique security feature (see Fig. 4). Such images are recorded using the laser card drive: the diffraction pattern created by the recorded pits results in a highly visible image on the optical media. This image cannot be altered, since the media is not erasable, and the permanent laser etching can be compared to more-readily changeable colored photographic image that can also be printed on the card. The visibility of the laser etching can be further enhanced by the use of a viewer, which relies on a simple light source and diffraction effects.Future developments

Current optical-card hardware is intended for use in home, office, or vehicles. Future developments will include battery-powered, hand-held readers. For example, authorities could use such portable readers to authenticate optical cards in the field. These smaller readers would be made possible by the availability of small-scale optics and integrated packages.

REFERENCE

- O. Yamada et al., IEEE Int. Symp. on Info. Theory and its Appl. 6(5), 95 (1990).

Christopher J. Dyball is executive vice president at Drexler Technology Corp., 2644 Bayshore Parkway, Mountain View, CA 94043; email: [email protected], and Terri Lichtenstein is an optical engineer at LaserCard Systems Corp., 2751 Marine Way, Mountain View, CA 94043; email: [email protected].