Paul S. Martin

One of the first commercial products available that addresses the potential for solid-state illumination, the Luxeon Ring, used here as an overhead table lamp, produces approximately 250 lumens from 12 high-power LEDs.

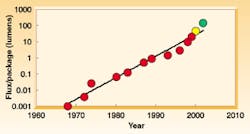

From 1968, when the first commercial light-emitting diodes (LEDs) were introduced at 0.001 lm/LED, until the mid-1990s commercial light-emitting diodes (LEDs) were used exclusively as indicatersthose ubiquitous lights that tell us when the power to our electronic gadgets is on, that illuminate numbers on alarm clocks, or that blink to tell us our automobile turn signals are flashing. Over the past 32 years, advances in LED technology have been consistent with Haitz's Law, which predicts a doubling of LED luminous output (flux, measured in lumens) every 18 to 24 months (see Fig. 1).

As LED technology has improved, high-power visible-LEDs are creating broad new markets for solid-state lighting, such as energy-saving traffic signals, color-enhancing backlights for televisions and monitors, and stylish-yet-rugged new forward lighting for automobiles. These markets require a high flux density, efficiency, and reliability that the traditional 5-mm indicator LED cannot provide.

First high-brightness LEDs

In the early 1990s, engineers at Hewlett-Packard's Optoelectronics Division (now LumiLeds Lighting; San Jose, CA) and Toshiba (Houston, TX) learned how to control the complex aluminum indium gallium phosphide (AlInGaP) epitaxial growth process on gallium arsenide (GaAs) substrates by using metal organic chemical vapor deposition. The AlInGaP material system allows creation of light in the red and amber regions of the spectrum.

Alloy ordering, hydrogen passivation of acceptor atoms, p-n junction placement, and oxygen incorporation into the aluminum-containing device layers proved to be substantial challenges that required nearly a decade to solve. The result was AlInGaP LEDs with internal quantum efficiencies approaching 100%. Nearly every electron and hole pair injected into a device resulted in the creation of a photon. The challenge then became how to get photons generated inside the semiconductor LED to the outside.

The first hurdle was to prevent light from being absorbed in the narrow-bandgap (0.87-nm) GaAs substrate. Techniques such as incorporation into the epitaxial structure of Bragg mirrors and direct growth on gallium phosphide (GaP) were attempted, but the most successful technique was brute-force removal of the GaAs substrate by etching, and replacement with GaP by wafer bonding.

At 25-lm/W efficiency, nearly 10 times the efficiency of a red filtered light bulb and several lumens per LED, these devices enabled the first LED stoplights on automobiles, red traffic signals, and single-color outdoor signs. However, at 3 lm/LED, use was still limited to applications in which the user had to look directly at the LED.

Blue and green high-brightness LEDs

Following the advances in AlInGaP, researchers at Nichia Chemical (Tokushima, Japan) and Nagoya University (Nagoya, Japan) learned how to control the very complex aluminum indium gallium nitride (AlInGaN) epitaxial growth process on sapphire substrates by using metal organic chemical vapor deposition. Aluminum indium gallium nitride material systems have a wider bandgap than AlInGaP ones, and allow access to the higher energy green and blue parts of the spectrum. Again, alloy ordering, hydrogen passivation of acceptor atoms, p-n junction placement, and oxygen incorporation into the aluminum-containing device layers proved to be substantial challenges.

FIGURE 1. Haitz's Law, which has held true for more than 30 years, predicts a doubling in LED luminous output every 18 to 24 months.

The AlInGaN material system is not as well understood as the AlInGaP material system, and internal quantum efficiencies at typical operating currents for AlInGaN green devices hover around 40% to 50%, while blue devices operate in the 60% to 80% range. By taking advantage of the transparent sapphire substrate and the greater sensitivity of the human eye to green light rather than either blue or red, several-lumen green LEDs have been introduced. When combined with lumen red AlInGaP and near-lumen-class blue LEDs, large, full-color signs can be made entirely from solid-state light sources.

Commercial white LEDs emerged soon after, using photons from a blue AlInGaN LED and a phosphor to convert some of the blue photons into its complementary coloryellow. The human eye sees this combination of blue and yellow light as a "dirty" white.

Solid-state lighting

With the convergence in the mid-1990s of major technological advances in AlInGaN and AlInGaP material technologies, LEDs have rapidly surpassed the efficiency of halogen, white tungsten, and color-filtered fluorescent light bulbs.

Light-emitting diodes offer important advantages such as lifetimes measured in tens of thousands of hours; they are rugged, yet classified as environmentally friendly; and their compact size allows a high flexibility in controlling the light with secondary optics.

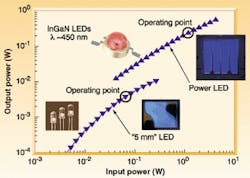

FIGURE 2. Today's high-power LEDs are more efficient than conventional 5-mm indicator LEDs.

The catch is that real lighting applicationsin which a light source is used to illuminate a desk, screen, or roomrequire not only high efficiency and long life, but also high flux and a reasonable price tag. A single 60-W incandescent bulb puts out 900 lm of white light300 times the amount of light that a typical phosphor-converted white indicator LED (PC LED) puts outfor a fraction of the cost per lumen. The key is designing LED devices and packages that can be driven at one to two orders of magnitude higher input power with the same high efficiency and reliability of traditional indicator LEDs.

New world of light

A line of high-power LEDs has been introduced by Lumileds Lighting, with guidance from Philips Lighting (Somerset, NJ), to address the potential in illumination. At 1.2-W input power, production versions of the Lumileds Luxeon devices operate at power levels 20 times greater than those of traditional 5-mm indicator LEDswith efficiencies as much as 50% greater and lifetimes measured in the tens of thousands of hours (see Fig. 2).

These devices come in red and amber AlInGaP versions, as well as green, blue, and white AlInGaN-based versions. Package thermal resistance has been reduced from the 300-K/W level of indicator LEDs to below 15 K/W. This reduction in thermal resistance allows application engineers to pump 20 times the power into the devices and get back out 55 lm of red light, 30 lm of green light, 10 lm of blue light, or about 25 lm of white light for phosphor-converted blue devices.

Next-generation products offer up to 110 lm of white light in a single 5-W package, which is equivalent to the light output from a 15-W incandescent light bulb, in a package that is less than 1% of the volume and requires only one-third of the power (see photo, p. 81). Twelve of these 110-lm devices are sufficient to make an automotive headlampnot a conventional 6-V automotive headlamp, but a cool blue high-intensity discharge-equivalent super-bright headlamp.

Single-color green versions of the 5-W devices offer luminous fluxes in excess of a 130-lm per package. Two of these sources can replace the 150-W light bulb in a typical 8- or 12-in. traffic signal, resulting in a 90% energy savings.

Red-green-blue combinations of these sources offer efficiencies that rival even cold cathode fluorescent lamps in applications such as backlighting for LCD televisions and monitors, where advantage can be taken of the compact source size and narrow color bands.

As LED technologies continue to improve, solid-state lighting will undoubtedly find more applications and continue to challenge traditional lighting sources.

PAUL S. MARTIN is the manager of R&D device development at LumiLeds Lighting, 370 West Trimble Road, San Jose, CA 95131; e-mail: [email protected].