Susan K. Jones and Webster E. Howard

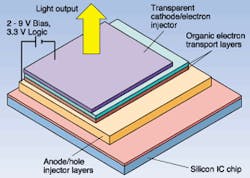

A combination of organic light-emitting diode (OLED) technology and complementary metal oxide semiconductor (CMOS) silicon technology is the primary enabler of an important new generation of microdisplays. The use of CMOS technology permits an astonishing amount of electronic complexity to be packaged on a small chip of silicon, and OLEDs have emerged as nearly ideal transducers for use with silicon active-matrix chips. Primarily used in near-eye microdisplays viewed with magnifying optics, the technology has recently been shown to be successful in hand-held microdisplays viewed without optics, and has been demonstrated to enable virtual images (see Fig. 1).

The OLEDs are easily formed from evaporated thin films laid on top of the silicon, the required voltages are low enough to allow use of low-cost, high-circuit-density silicon devices, and the optical characteristics are well-suited for use with low-cost, large field-of-view magnifiers. They are efficient, resulting in low power consumption, and the fact that they emit light rather than modulate transmitted or reflected light results in smaller and lighter viewing modules. The integration of OLEDs with integrated circuits (ICs) permits many computer and video electronic system functions to be built directly onto the silicon IC under the OLED layer, resulting in an ultracompact system with lower overall system costs.

The technology is often used in near-eye microdisplays, a type of flat-panel display used in small optically viewed devices such as video headsets, camcorders, viewfinders, and other portable devices. Typically, these displays have pixels of such high resolution (not resolvable with the naked eye), that they are ideally viewed with optics placed near the eye. Although near-eye microdisplays are small (typically less than 1 sq. in.), many can provide a magnified viewing area similar to that of a full-size computer screen. For example, when viewed through a lens, a high-resolution 0.6-in. diagonal display can look like a 19-in. diagonal computer screen or a large TV screen.

OLED technology

Organic light-emitting diodes represent a new generation of display technology, not only for microdisplays but also for direct-view displays. A typical OLED of the variety pioneered by Kodak is formed by starting with a transparent electrode of indium tin oxide (ITO)—which also happens to be a good emitter of "holes"—an empty state in an electron distribution (see Fig. 2). The ITO is covered with a thin layer of copper phthalocyanine, which passivates the ITO and provides greater stability. Then, a p-type hole transport material, for example, a naphthaphenylene benzidine (NPB), is deposited, followed by an n-type emitter material such as aluminum hydroxyquinoline (Alq). Finally, a cathode of magnesium silver alloy is deposited for easy injection of electrons. All of the films can be evaporated, making fabrication very simple. Electrons and holes recombine at the interface of the n-type and p-type materials and emit, in this case, green light. We use a different but similar structure and materials to create large arrays of top-emitting full-color-spectrum white-light diodes.In an OLED microdisplay, a stack of thin solid organic films totaling less than 1 µm is applied to the electrodes on the surface of the silicon. Because the substrate is opaque in this case, the top electrode, usually the cathode, is made semitransparent to allow the emission of light. A small electric current through each electrode causes the organic structure to emit light in an amount proportional to the current. The active matrix array is provided on the silicon IC underneath, along with considerable other circuitry to minimize the requirements for other ICs. Because the light is constantly emitted in almost all directions there are no significant variations with angle or time, and consequently, almost no variations over the exit pupil of the optics or flicker.

Color is achieved by having a full-color-spectrum white emitter and overlaid color filters, which provide subpixels of red, green, and blue similar to that of a color TV tube or LCD notebook display. The result is a life-like image, even when highly magnified, to create a large field of view. The handling of color information in parallel, rather than sequentially, results in lower power consumption and eliminates the need for an illumination source. This simplifies and lightens the optics requirement for the display, relative to a light-valve approach.

A single low-cost molded optical element can provide a large field-of-view virtual image. Emitted light is not polarized as in LCDs, so low-cost lightweight optics can be used with minimal risk of chromatic or pattern distortion due to birefringence. Since the light-emitting sources only use power where light is needed, they can be more efficient than a liquid-crystal-on-silicon display, which requires a full area illumination source.

Applications

Emerging microdisplays have the potential to produce a revolution in the capability of hand-held and head-worn portable devices. Whereas today's hand-held devices are limited to a relatively few lines of text on a 3-in. screen, OLED microdisplays can offer a bright virtual image similar to that of a 14- to 19-in. computer monitor or a 25- to 60-in. TV screen with a large field of view, while consuming low power.

Another type of interface—headset systems—are computer enablers that provide a large-screen view, privacy, a second virtual monitor for portable or desktop monitors, or a large virtual screen for portable DVD players. Video headsets also can be used in games with head-motion tracking and stereovision for exciting, immersive entertainment-related applications. Video and data headsets fill the increasing demand for instant data accessibility in mobile work environments such as public safety, maintenance, manufacturing, construction, field service, health care, transportation, military, and avionics.

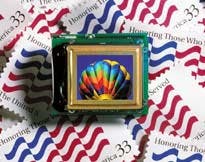

Recently, IBM Research (Yorktown Heights, NY) developed with eMagin Corp. what is believed to be the first OLED-on-silicon microdisplay capable of being viewed directly, without magnifying optics. The OLED microdisplay is capable of rendering high-resolution images with a pixel density of 740 pixels/in., in a VGA 640 x 480 format. In addition to text and graphic images, pictures containing gray-scale images may also be shown using dot-density methods producing photograph-like images. The display has sufficient brightness and contrast to be viewed in sunlight but can be dimmed by software control for use in ambient light. The use of silicon-chip technology allows several functions to be integrated, including SRAM memory function at each pixel, simplifying system requirements. A prototype of the display was demonstrated as a wristwatch computer, notable for its Linux operating system.

The first commercial OLED microdisplay product is being produced by eMagin and is an SVGA+ color display with 852 x 3 x 480 subpixels (see Fig. 3). This display consists of 15-µm2 pixels, yielding a diagonal size of about 0.62 in. Its color gamut exceeds that of leading notebook displays and the total power consumption at 100 cd/m2 is less than 300 mW for running full-color video from a PC. The chip accepts multiple RGB analog inputs, connecting easily to the monitor output of a PC.Progress

While early diodes did not have sufficient efficiency or life to be commercially attractive, the progress in improving these factors has been astounding, probably in part because of the infinite variety of organic compounds that can be synthesized, even within the class of conjugated materials. In contrast with the case of conventional crystalline semiconductors, the fabrication processes allow the possibility of making very-high-resolution displays. Also, full color was quickly achieved, whereas it took almost 30 years to get reasonably efficient blue LEDs.

In most of the wearable and hand-held microdisplay applications, OLED on silicon competes with liquid crystal on silicon (LCOS). The OLED's basic characteristics, however, provide several benefits over an LCD or LCOS alternative. Because OLED-on-silicon microdisplays emit light with the same high brightness and contrast at all forward viewing angles, they permit a larger field of view across a larger exit pupil, with simpler and lighter optics.

Organic LEDs switch at submillisecond speeds, much faster than liquid crystals, especially at low temperatures. This ability allows excellent renditions of fast-action video, as in sports or games. The overall performance of OLEDs over a wide temperature range meets even the stringent requirements of military customers. No color breakup occurs in this type of OLED design even when used in fast-motion, large field-of -view, or vibrating environments. One unusual requirement of value to the military is the ability to generate extreme levels of luminance (>30,000 cd/m2) without losing resolutionwhich OLEDs have been shown to be capable of.

Clearly, OLED technology can greatly benefit both direct-view and microdisplay applications. In both cases, OLEDs offer higher efficiency and lower weight than competing liquid-crystal displays because they do not require backlights or reflective light sources. These are important attributes for wearable, head-mounted, and portable products for consumer, industrial, and military applications.

SUSAN K. JONES is cofounder and chief marketing and strategy officer and WEBSTER E. HOWARD is chief technology officer at eMagin Corp., 2070 Route 52, Hopewell Junction, NY 12533; e-mail: [email protected]; [email protected].