Australian researchers have reported cooling optical fiber below room temperature using laser light, a promising step toward manufacturing high-output lasers with no internal heat generation, Such laser cooling is a result of anti-Stokes fluorescence at very high quantum efficiency, and may offer an efficient alternative to Peltier devices. A team of physicists led by Anton Rayner at the University of Queensland (Brisbane, Queensland, Australia), claims to have demonstrated the first prototype optical refrigerator by use of a compact and inexpensive laser source.

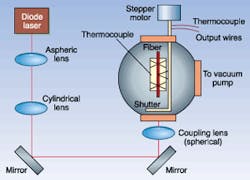

The group directed 1 W of power from a 1013-nm diode laser into a 250-µm-diameter fiber (see figure). The fiber to be cooled was ytterbium-doped ZBLAN (fluorine combined with zirconium, barium, lanthanum, aluminum, and sodium), commercially manufactured by KDDI Research and Development Laboratories (Saitama-ken, Japan). The fiber was supported on two pairs of crossed silica optical fibers inside a vacuum chamber, evacuated to less than 10-5 Torr to minimize heat load.1

Light from the laser diode was collimated by an aspheric lens and coupled into the cooling fiber. Successful cooling depends greatly on efficient coupling of the multimode output of the laser light into the fiber—which was difficult, reports the team. Optimal cooling resulted from the use of a 10-cm-long piece of fiber, enabling use of a coupling lens with a shorter focal length.

Two methods of temperature measurement were applied to monitor cooling—fluorescence along the length of the fiber, and a 50-µm-diameter junction microthermocouple in direct contact with the fiber. In the first method, fluorescence from the fiber was collected normal to the pump light with a 5-cm lens positioned outside the vacuum chamber. The fluorescence results measured cooling by 3.7 K, with 1 W of incident light at 950 nm. In the second method, a rotating stepper motor caused the nickel-based fine-gauge thermocouple to periodically come into contact with the cooling fiber, which then measured a corresponding 1-K drop in the temperature at different points. The two temperature schemes were calibrated and scaled for comparison.

Although the drops in temperature measured via the two methods are similar and scale directly with power, they do differ significantly. To explain this difference, the researchers propose that the fluorescence method measures the internal temperature of the fiber, which does not necessarily match the external temperature of the fiber. Another explanation is that the fiber may absorb heat from the thermocouple and cause the equilibrium temperature to be higher than the cooled fiber. Also, differences between the two measurements may be due to any impurities in the fiber.

The thermocouple measurements showed that the drop in temperature was consistent along the length of the fiber. Such a cooled fiber could refrigerate another object at any point along its length, demonstrating the first commercially viable prototype solid-state laser cooler. Although the beam quality of the diode in this case was poor, the scientists believe that the use of a higher-power diode laser with good beam quality would significantly improve cooling efficiency.

REFERENCE

- A. Rayner, M. Hirsch, N. Heckenberg, and H. Rubinsztein-Dunlop, Appl. Opt. 40, 5423 (2001).

About the Author

Valerie Coffey-Rosich

Contributing Editor

Valerie Coffey-Rosich is a freelance science and technology writer and editor and a contributing editor for Laser Focus World; she previously served as an Associate Technical Editor (2000-2003) and a Senior Technical Editor (2007-2008) for Laser Focus World.

Valerie holds a BS in physics from the University of Nevada, Reno, and an MA in astronomy from Boston University. She specializes in editing and writing about optics, photonics, astronomy, and physics in academic, reference, and business-to-business publications. In addition to Laser Focus World, her work has appeared online and in print for clients such as the American Institute of Physics, American Heritage Dictionary, BioPhotonics, Encyclopedia Britannica, EuroPhotonics, the Optical Society of America, Photonics Focus, Photonics Spectra, Sky & Telescope, and many others. She is based in Palm Springs, California.