Excimer lasers machine in the UV

JIM HIGGINS

Excimer lasers offer the most efficient access to the ultraviolet (UV) spectral region of any laser source, leading to high pulse energies and high average and peak powers, attributes that make them a powerhouse for ultraviolet machining applications. However, they exhibit relatively poor beam quality (high-order mode structures and high divergence) and a lingering reputation for finicky performance—now largely undeserved due to the advances in the technology over the past 5-10 years.

Excimer lasers are pulsed gas lasers that use a mixture of gases to provide emission at a series of discrete wavelengths in the UV region of the spectrum. The word "excimer" is a contraction of the term "excited dimer." This describes a diatomic molecule that is bound in its electronically excited upper state, but is repulsive or only weakly bound when in the lower ground state. The laser gas mixture is usually excited by means of a fast electric discharge lasting only a few tens of nanoseconds. This causes the formation of the excited molecule, and, as a result of the transition of this short-lived species, laser action takes place back to the repulsive ground state, where the gases revert to their original separate constituents, enabling the process to be repeated.

Closely spaced electrodes used in the excitation process provide an adequate gain volume. The resulting laser beam is rectangular in cross section with an aspect ratio between 1 and 3. A typical dimension would be 1 x 2.5 cm.

In a typical excimer gas mixture, approximately 2% of the gas is a noble gas, 0.2% is a halogen gas and the balance of several thousand millibar is a buffer gas, usually neon. The mixture of laser gases is confined within a pressure vessel, usually at a total pressure between 3500 and 5000 millibar.

The wavelength emitted depends upon the selection of rare and halogen gases: argon, krypton and xenon and the halogen gases fluorine or chlorine (supplied in the form of HCl). The halogen gases are usually supplied diluted by the buffer gas in concentrations of between 5% and 10%.

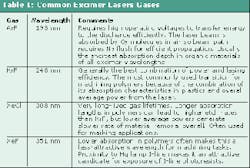

Table 1 shows the most commonly used combinations of excimer laser gases and outlines the practical attributes of each transition.Molecular fluorine, F2, which lases at 157 nm is a comparatively inefficient laser medium, but its short wavelength is attractive from a materials absorption standpoint. The difficulty of transmitting it to the workpiece has resulted in very few such lasers being used in practical tasks to date.

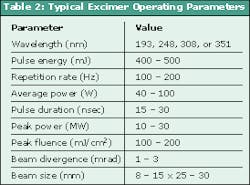

Typical operating parameters for excimer lasers used in most industrial tasks are given in Table 2. In addition, some small, lower powered units (<30 W and 10 to 50 mJ) are used in tabletop micromachining or low-volume manufacturing.Resonators

Most excimer lasers are used with stable resonators. The high gain of the excimer medium requires output coupling reflectivities of 10% to 30% for most efficient energy extraction. Typical beam divergences are then on the order of 2-3 mrad. When lower divergence is required, these lasers may be equipped with high-magnification unstable resonators that reduce the beam divergence to a value between 200 and 400 µrad in a beam with 60% to 70% of the energy obtained with a conventional, stable resonator.

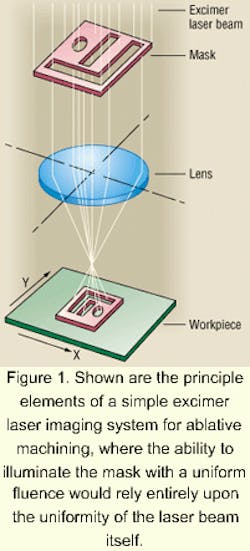

With a stable resonator, the typical beam divergence is approximately 3 mrad, which represents a poor beam for producing small or precise features in a focused beam application. However, excimer laser machining is normally performed by illuminating an aperture with the laser beam and forming a demagnified image of the aperture on the workpiece to achieve the desired feature size and the laser fluence needed to ablate material from the workpiece. In such an optical system, the beam divergence has less importance providing it is sufficient for the laser energy to be captured by the finite aperture of the final imaging lens.

Figure 1 shows the principle elements of a simple excimer laser imaging system for ablative machining where the ability to illuminate the mask with a uniform fluence would rely entirely upon the uniformity of the laser beam itself. Most excimer laser beams exhibit a reasonably flat-topped profile in their long axis, with a more-peaked distribution in the short one. The effects of beam inhomogeneity at the workpiece will be determined by the power dependence of the material being processed. In cases where the uniformity is critical, external beam homogenizers improve spatial uniformity to within a few percent. Invariably, these devices cause a significant increase in the divergence of the laser beam and require subsequent optical elements to be large enough to collect this more-divergent beam for efficient utilization of the laser energy.

Lifetime, care, and maintenance

The three main elements in the lifetime and maintenance of excimer lasers are: the laser gas, laser optics, and the high-voltage discharge components.

Because excimer lasers are not sealed-off devices, the laser gas deteriorates with use, and therefore the laser is normally left connected to gas bottles that replenish the gas fill in its entirety once its performance is no longer adequate.

Two separate mechanisms explain the deterioration of the laser gas with use. In the first, gaseous impurities evolve within the laser and reduce the laser output by absorbing laser light within the pressure vessel. In the second, removal of halogen by interaction with the material of the vessel causes its concentration to fall below the optimum value. The net effect of both is to reduce laser efficiency over time.

To compensate, a system continuously monitors the level of laser output and adjusts the power input to the laser to maintain constant optical output as the gas fill ages. Simultaneously, the laser control will introduce small quantities of halogen gas (injections) to the gas mix as a software algorithm predicts its depletion.

In all modern excimer lasers, careful selection of materials, particularly the elimination of organic materials used as insulators, seals, or lubricants, minimizes these effects. Additionally, cryogenic gas processing may be used to selectively freeze gaseous impurities into a solid form in an external gas processing system from which they can later be removed. In combination, these techniques now make it possible to operate an excimer laser for intervals in excess of 100 million pulses between exchanges of laser gas.

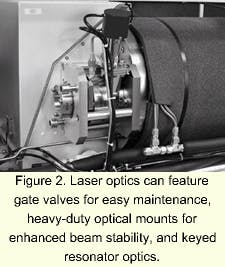

Small particles generated inside the pressure vessel by sputtering of material from the main discharge and pre-ionization electrodes can settle on the laser optics causing a loss of efficiency and output. Electrostatic gas filtration and control of gas flow near the laser optics minimizes this effect. Despite this, the laser optics must be removed and cleaned, typically after an interval of 50-100 million pulses. Industrial excimer lasers contain valves that seal the pressure vessel and retain the gas fill while optics are removed for cleaning, minimizing cleaning time and providing operator protection from escaping halogen gas while the optics are removed.KrF, XeCl and XeF laser optics will normally require replacement after 500 million pulses. ArF optics, which degrade more quickly, require replacement at more-frequent intervals.

High-voltage components wear and eventually require replacement. Of these, the laser vessel represents the most significant work and cost to replace. Its replacement is dictated principally by erosion of the main discharge and preionization electrode structures. The lifetime of a laser vessel is typically on the order of 1-3 x 109 pulses.

Other components in the discharge circuit (triggering components, high-voltage power supplies, control electronics) are subject to statistical failure. These will typically demonstrate lifetimes of 2-10 x 109 pulses before requiring replacement.

Dr. Jim Higgins is Product Manager for Laser Sources with GSI Lumonics, Kanata, Ontario, Canada. He can be contacted at (P) 613/592-1460, (F) 613/592-5706. or [email protected].