Philippe Bado

In the early nineties, scientists at the University of Michigan (Ann Arbor, MI) discovered that the transfer of heat generated by the beam/workpiece interaction could be overcome using ultrafast laser pulses instead of standard long-pulse lasers. Essentially, machining with laser pulses of very short duration eliminates heat flow to surrounding material. This discovery opened the way for fine-feature laser micromachining.

In essence, ultrafast or ultrashort means that the laser pulse is less than about 10 ps—usually in femtoseconds. Long means that the pulse is longer than about 10 ps, that is longer than the heat-diffusion time.

The most fundamental feature of material interaction in the long pulse regime is that the heat deposited by the laser in the material diffuses away from the work zone during the pulse duration. Technically speaking, the laser pulse duration is longer than the heat diffusion time. This may be desirable if you are doing laser welding, but for most micromachining jobs, heat diffusion into the surrounding material is undesirable.

Heat diffusion reduces the efficiency of the micromachining process by taking energy away from the work spot—energy that would otherwise go into removing material. Heat diffusion also reduces the temperature at the focal spot, keeping the working temperature not much above the melting point of the material.

Material is removed by depositing energy into the melted material, which boils, ejecting globs of the molten material away from the work zone. The ejected globs form drops that fall back onto the surface and contaminate the sample. They retain a fair amount of residual heat and may bind strongly to the sample. Removal of these contaminants may be difficult or impossible without damaging the target. These droplets may also contaminate the beam delivery optics. It is very difficult to go much above the melting point because the energy moves away from the machining spot as fast as it deposited there by the laser beam.

Heat diffusion can also reduce the accuracy of the micromachining operation. Typically, heat diffuses away from the focal and melts an area that is larger than the laser spot size, making it difficult to do very fine machining. Thus, while the minimum laser spot size might be in the range of one micron, it may not be possible to create features with dimensions much smaller than a few tens of microns.

A zone around the machining spot is referred to as the heat-affected zone or HAZ. The heating (and subsequent cooling) waves that propagate through the HAZ may cause mechanical stress and can create microcracks in the surrounding material. In subsequent routine use of the workpiece, these cracks may propagate deep into the bulk of the material and cause premature device failure. A closely associated phenomena involves the formation of a recast layer of material around the hole with physical and/or chemical structures that are different from the original material. This recast layer may be mechanically weak and it may break away from the unheated core material after some time. In some applications, this recast layer is removed through extensive and expensive post-process cleaning.

Heat diffusion also is sometimes associated with the formation of surface shock waves. These shock waves can damage nearby device structures or can delaminate multilayer materials. While the amplitude of the shock waves varies with the material being processed, it is generally true that the more energy that is deposited in the micromachining process, the stronger the associated shock waves are.

Clearly, when micromachining with long laser pulses, heat diffusion dominates the material removal process, so reducing, or eliminating, heat diffusion is therefore highly desirable.

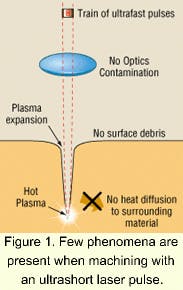

The most fundamental feature of laser micromachining with ultrafast pulses is that the duration of the laser pulse is shorter than the heat diffusion time (see Figure 1). Because the energy does not have the time to diffuse away, the efficiency of the machining process is high. The laser energy has nowhere to go (or more precisely does not have the time to move away). It just piles up at the level of the working spot, where the temperature rises instantly past the melting point of the material and goes, very quickly, well beyond even the evaporation point. The temperature climbs into what is called the plasma regime.

Ultrafast lasers deliver incredible intensity levels, which can easily reach the range of hundreds of terawatts per square centimeter at the work spot. No materials can withstand the forces at work at these power densities. This means that ultrafast laser pulses can machine very hard materials, as well as materials with extremely high melting points such as molybdenum or rhenium (see Figure 2).The plasma created by the ultrafast laser pulses expands outward, away from the work surface in a highly energetic gas plume. The internal forces that previously held the material together are vastly insufficient to contain this hot gas expansion. Consequently, there are no droplets that condense onto the surrounding material. Rather, material redeposition, if there is any, is in the form of a very fine powder. Additionally, since there is no melt phase, there is no splattering of material onto the surrounding surface. Post processing, if needed, is limited to a gentle flush with dry air.

The plasma expansion consumes most of the energy deposited by the ultrafast laser pulses. Consequently, very little heat is left behind to produce a heat-affected zone. The shock effects associated with heat wave propagation, microcracks for example, are avoided even for brittle material like ceramics.

Philippe Bado is vice president of technology at Clark MXR, Dexter, MI, (P) 734-426-2803 ext. 220 or [email protected].

Reprinted from Industrial Laser Solutions, March 2000.