SOLID-STATE LASERS: VBG upper-state pumping benefits DPSS lasers

Industrial diode-pumped solid-state laser systems are rapidly transforming to meet market demands for increased output power, near-diffraction-limited optical profile, and linearly polarized output. Improvements in output power improve process throughput and enable new applications in micromachining, materials processing, spectroscopy, wafer inspection, laser display, and medical diagnostics. Furthermore, the excellent beam quality and linear polarized output result in efficient second- and third-harmonic generation of additional wavelengths.

Historically, the industrial workhorse of DPSS lasers has been neodymium:yttrium aluminum garnet (Nd:YAG) pumped at 808 nm due to the large absorption cross-section, broad absorption linewidth, and good thermal properties of the host crystal. Unfortunately, the performance of this system is limited due to the high quantum defect between the 808 nm pump light and the 1064 nm laser emission, leading to thermal lensing and corresponding poor spatial-beam quality. In addition, the isotropic nature of the YAG crystal leads to randomly polarized output, reducing the efficiency of harmonic-generation processes.

Clearly, alternate materials systems and pumping methods including volumetric Bragg grating (VBG)-based—used interchangeably with the term volume holographic grating (VHG)-based—or even on-chip grating-based techniques are required to increase output power, improve the optical-to-optical efficiency, and improve beam quality for future DPSS systems.

Upper-state pumping options

Neodymium:yttrium orthovanadate (Nd:YVO4) crystals are increasingly being used for DPSS systems due to their large stimulated emission cross-section, high absorption coefficient, high laser damage threshold, and linearly polarized output. Improved power scaling and efficiency can be achieved by upper-state pumping of Nd:YVO4 solid-state lasers at 878 nm due to an approximate 30% reduced quantum defect and corresponding reduction in the thermal load and reduced thermal lensing.1

The improvements in output power, beam quality, and output polarization gained by using vanadate-based crystals place tight specifications on the laser diode pumps. Since vanadate crystals are naturally birefringent, the upper-state absorption linewidth is narrow and strongly polarization dependent, forcing tight specifications on spectral width and wavelength emission stability over varying operating temperatures and operating currents for high-power laser diode pump sources. And because the brightness and spatial profile of the diode pump intensity can have a significant impact on the output power, beam intensity, and efficiency of the DPSS system, wavelength-stabilized pump sources are required. Fortunately, the system-level tradeoffs in implementing one solution-VBG-based laser diode pumping-can be quantified with respect to cost, power, efficiency, and dynamic range.

VBG pumping

The optical lasing spectra of quantum-well semiconductor lasers are closely related to the optical gain spectrum of the active region, which is heavily dependent on the drive current and temperature of the laser diodes. Standard broad-area laser diodes do not use wavelength-selective feedback mechanisms, resulting in lasing on any and all modes that experience sufficient round-trip gain within the spectral gain bandwidth of the active region. The envelope spectral width of the lasing modes is therefore predominantly dependent on the spectral width of the optical gain, which is itself proportional to the square of the emission wavelength.2

Due to changes in the bandgap and corresponding optical gain spectrum of diode lasers with temperature and operating current, the laser spectrum shifts at the rate of approximately 0.3 nm/°C for unstabilized laser diode devices. In other words, the spectral width and central wavelength change substantially with laser operating conditions and cannot be directly engineered through epitaxial modifications alone.

Wavelength stabilization of laser diodes is typically achieved through wavelength-selective feedback that locks the laser to one (or a few) longitudinal modes using such common approaches as internal feedback via etching a grating in the active region as is done for distributed Bragg reflector (DBR) or distributed feedback (DFB) lasers, or by external feedback with, for example, VBG optics.3

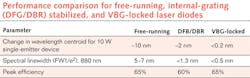

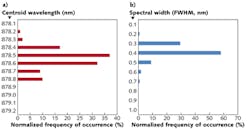

The VBG wavelength-locking method offers several advantages over DFB- or DBR-locked devices (see table). First, external VBG locking decouples diode-self-heating from the wavelength detuning of the feedback structure, further improving the temperature stabilization of the locked diode and allowing for wavelength-tunable laser emissions via independent temperature control of the VBG element. Devices that incorporate internal gratings such as DFB or DBR lasers suffer from 0.07 nm/°C wavelength shift with temperature, leading to a 2 nm shift in lasing wavelength over the operating power. In comparison, the low optical absorption of the VBG means a wavelength shift of less than 0.2 nm over the operating range of the product; that is, VBG-locked devices show the smallest change in centroid wavelength, the lowest demonstrated spectral linewidth, and uncompromised electrical-to-optical efficiency (see table).

Second, VBG locking offers greater flexibility in wavelength because longitudinal lasing modes are selected by an external optic. The emission linewidth can be tailored to the application: In the case of very narrow linewidth requirements (less than 0.05 nm), the VBG can simply be made thicker. For example, nLIGHT has recently demonstrated wavelength-stabilized laser diodes at 780 nm that have a spectral linewidth at less than 10 pm for the entire operating range.

Third, by eliminating the additional epitaxial processes required in on-chip gratings, the voltage defect of electrically injected devices can be substantially reduced, leading to an increase in wall-plug efficiency. The epitaxy can be independently optimized for high power and high efficiency without the need to compromise the design for good grating coupling to the optical mode required by buried-grating approaches. The low internal loss of the grating itself allows design optimizations that provide zero penalty in the power and efficiency relative to the unlocked design. External locking eliminates the need for complex epitaxial regrowth methods typically used in buried grating approaches. Alignment leverages the same well-developed techniques used in fast-axis collimation and lensing, and wavelength-unlocked and -locked products can be built from chips of the same wafer.

Finally, recent advances in volume manufacturing capabilities and competitive pricing pressures have reduced the cost of the optics, making VBG a low-total-cost solution.

External VBG performance

Previous work by other groups has shown an approximately 10–20% penalty to the slope efficiency of the laser diode after external wavelength locking by means of a VBG. In order to address this limitation, nLIGHT recently developed a locking technique capable of maintaining good locking performance over a wide temperature range with virtually no change to the laser power and efficiency.4

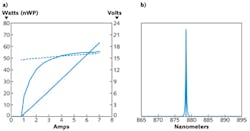

More recently, the technique was applied to multiple high-power, high-efficiency laser diodes operating at wavelengths across the 800–1900 nm band, including our 88x nm fiber-coupled Pearl modules, enabling devices with very narrow spectral linewidths and fiber-coupled electrical-to-optical efficiencies well above 55%—key parameters for upper state pumping of vanadate-based DPSS lasers (see Fig. 1).The advent of low-cost, fiber-coupled pump modules has enabled significant improvements in DPSS pumping architectures. The multimode fiber defines the spatial profile of the pump light, providing a circular output beam with good spatial overlap with the solid-state laser (SSL) signal. Second, the pumps can be packaged separately from the SSL crystal, simplifying cooling requirements for the system.

nLIGHT has pioneered methods for simultaneously depolarizing the pump light and homogenizing the numerical aperture output from the fiber. This technique significantly depolarizes the laser light while improving the stability and serviceability of the fiber-coupled pump modules. Finally, by homogenizing the near-field and far-field optical beams, the pump module profile is better matched to the SSL fundamental mode profile, improving the optical-to-optical efficiency and attainable diffraction-limited output power.

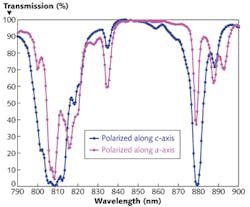

A number of our customers pump Nd:YVO4 SSLs using wavelength-stabilized, fiber-homogenized pump sources at 878.6 nm. When performing comparative studies of pumping at 808 nm vs. 878 nm diodes, the difference in the absorption curve for a-axis compared to c-axis polarized light has a significant impact on laser performance (see Fig. 2). When pumping at 878.6 nm, customers typically report a substantial improvement in the maximum output power over the 808 nm-pumped device. However, the difference between a-axis and c-axis absorption places tight requirements on the pump wavelength and spectral width, balancing these requirements.Numerous customers have reported that the optimal wavelength for pumping Nd:YVO4 is 878.6 nm, with tight tolerance on the spectral width and center lasing wavelength. By pumping at 878.6 nm, the absorption along the a-axis and c-axis is balanced, leading to high output powers with minimal thermal lensing. The spectral linewidth must be sufficiently narrow (approximately 0.5 nm at full-width half maximum or FWHM) so that the a-axis and c-axis absorption values do not change substantially over the spectral width of the pump.

When detuning the pump to 878.1 nm, the low a-axis optical absorption leads to poor performance. Larger spectral widths (on the order of 1 nm) have substantially reduced performance due to the rapid reduction in the a-axis absorption, reducing the diffraction-limited beam quality for pumps with a short wavelength. By tuning the pump to wavelengths above 879.1 nm, the strong c-axis absorption coupled with the weak a-axis absorption leads to low optical-to-optical efficiency and strong thermal lensing, and further increases in the spectral linewidth cause degradations in the DPSS performance.

By maintaining a narrow spectral linewidth, excellent center-wavelength stability, depolarized laser output, and good optical homogeneity, we can simultaneously optimize absorption along the a and c axes while mitigating thermal lensing, resulting in substantial improvements in output power and slope efficiency as compared with 808 nm pumping (see Fig. 3).High power and linearly polarized output of 878.6 nm pumped Nd:YVO4 directly lead to improved harmonic generation of solid-state devices. Based on customer feedback, 878.6 nm-pumped devices lead to an improvement greater than 60% in TEM00 output power over 808 nm-pumped devices, corresponding directly to significant improvements in output power levels achievable through first and second harmonic generation.

REFERENCES

1. Y. Sato et al., Appl. Phys. Lett., 82, 6, 844–846 (2003).

2. S.M. Sze, Physics of Semiconductor Devices, Wiley, New York, NY, 2nd ed. (1981).

3. B. Volodin et al., Opt. Lett., 29, 16, 1891–1893 (2004).

4. P. Leisher et al., "High-Performance Wavelength-Locked Diode Lasers," Proc. SPIE, 7198 (2009).

About the Author

Michael Atchley

Director of Product Marketing, nLIGHT

Michael Atchley is director of product marketing at nLIGHT (Camas, WA).

Kirk Price

Senior Product Development Manager, nLIGHT

Kirk Price is senior product development manager at nLIGHT (Camas, WA).