Quantum dots integrated into photonic crystals produce polarized light output ideal for displays

Ordinary light sources used in liquid-crystal displays (LCDs), such as LEDs or compact fluorescent lamps, emit unpolarized light; however, because LCDs require polarized light, these conventional light sources must be placed behind a polarizing sheet that absorbs half the light. Recently, quantum dot (QD) light sources have moved from the research lab into commercial products like high-end TVs, e-readers, and laptops. In one form of display, QDs, which have brighter colors, are used to replace the standard backlight source. However, QDs embedded in a conventional matrix still emit unpolarized light, necessitating the efficiency-reducing polarizing sheet.

Now, a team of researchers from the University of Illinois at Urbana-Champaign has produced an integrated QD and photonic-crystal structure that naturally emits polarized light, without the usual 50% cut in efficiency from a polarizing sheet. The new method extracts more-efficient and polarized light from QD over a large-scale area.1 The approach could lead to brighter and more efficient mobile-phone, tablet, and computer displays, as well as enhanced lighting.

8X enhancement

With funding from the Dow Chemical Company, the research team embedded QDs in novel UV-cured polymer materials that retain strong quantum efficiency. They then used electrohydrodynamic jet (E-jet) printing technology to precisely print the QD-embedded polymers onto photonic-crystal structures. The precision eliminates wasted QDs, which are expensive to make.

At the center wavelength of its resonance band, the photonic crystal resulted in an eightfold light-output enhancement from the QDs.

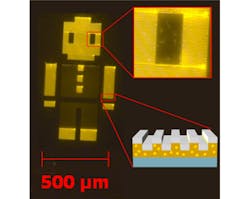

To demonstrate the technology, the researchers fabricated a novel 1 mm device (with they call Robot Man) made of yellow photonic-crystal-enhanced QDs. The device contains thousands of quantum dots, each measuring about 6 nm in size.

"We made a tiny device, but the process can easily be scaled up to large flexible plastic sheets," says Gloria See, one of the researchers. "We make one expensive 'master' molding template that must be designed very precisely, but we can use the template to produce thousands of replicas very quickly and cheaply."

Source: http://engineering.illinois.edu/news/article/11571

REFERENCE:

1. Gloria G. See et al., Aplied Physics Letters (2015); http://dx.doi.org/10.1063/1.4927648

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.