Phosphors for white-light LEDs have no rare-earth materials

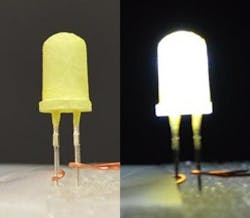

Researchers at Rutgers University (New Brunswick, NJ) have created a white-light LED using a phosphor that does not contain any rare-earth materials, thus reducing the cost of the LED and eliminating reliance on the rare-earth materials, which are in limited supply and whose production is controlled mostly by a very few countries. Conventional white LEDs combine a blue emitter with a yellow-emitting phosphor made of rare-earth elements such as yttrium aluminum garnet (YAG).

The scientists discussed their research at the 250th National Meeting & Exposition of the American Chemical Society (ACS) held August 16-20, 2015 in Boston, MA.

Metals plus organics

The team, led by Jing Li, is developing hybrid phosphor-based technologies that combine common, earth-abundant metals with organic luminescent molecules to produce phosphors that emit a controllable white light from LEDs. By varying the metal and organic components, the researchers can systematically tune the color of the phosphors to regions of the visible light spectrum that are most acceptable to the human eye. The team is continuing to experiment and develop other rare-earth-free LED phosphors based on different metals and organic compounds.

Many material combinations are possible, so the the researchers use a computational approach to initially sort through the possibilities and to predict what color of light the various metals and organics combinations will emit. They then test the best combinations experimentally. Their approach allows a systematic fine tuning of bandgaps and optical emissions that cover the entire visible range, including yellow and white colors.

"One of challenges we had to overcome was to figure out the right conditions to synthesize the compound," notes Zhichao Hu, one of the researchers. "Like cooking, the synthesis requires a 'recipe.' It's often not the case that one can simply mix the starting materials together and get the desired product. We optimized the reaction conditions—temperature and the addition of a solvent—and developed an easy procedure to make the compound with high yield."

Experiments with some materials have shown that the team's technology can cut LED costs by as much as 90% from current methods that rely on rare-earth elements. They have several granted and pending U.S. patents and are exploring manufacturing possibilities.

Source: http://www.acs.org/content/acs/en/pressroom/newsreleases/2015/august/white-leds.html

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.