Tiny laser-switched magnetic structures could produce better hard drives

Paul Scherrer Institute (PSI; Villigen PSI, Switzerland) researchers have succeeded in switching tiny, magnetic structures using laser light that could enable faster, more compact, and more efficient data storage on computer hard drives.

RELATED ARTICLE: Can new techniques continue to densify optical data storage capacity?

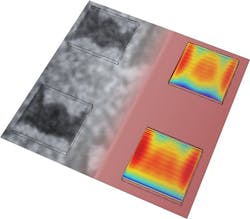

In order to capture larger amounts of data on smaller hard drives, researchers and developers are trying to make the actual size of the magnetic bits and bytes increasingly smaller. With this in mind, researchers from the Paul Scherrer Institute (PSI) are relying on the combination of a micro-structured surface and a laser beam. The surface consists of a regular arrangement of tiny squares made of a magnetic material. In the researchers' various tests, these squares had a side length of between one and five thousandths of a millimeter.

In the second part of the unconventional approach, the PSI scientists are able to reverse the magnetic direction of the squares specifically using a laser beam. In today's hard drives, the magnetic switching and thus the storage of data occurs with a small magnetic head, which glides over the hard drive like the needle on a record player.

The researchers at PSI teamed up with colleagues from the Netherlands, Germany and Japan for the project. Two years ago, the international research team already succeeded in demonstrating that a short, intensive laser pulse can switch micro-magnets hundreds of times faster than a magnetic head. And the laser is lower in energy and thus more cost-effective, too. The trick evidently lies in the fact that the laser light heats up the tiny magnets very quickly and is thus able to convert them into the other state. "Using light for magnetic switching clearly works. But why exactly it does is still the subject of debate in the research community," explains Frithjof Nolting, the lab head on the PSI study.

To gain a better understanding of this magnetic reorientation process, the researchers have now developed a time-resolved measurement that enables them to observe the lightning-quick changes one step at a time using x-radiation from the Swiss Light Source (SLS) at PSI. They managed to produce a series of snapshots that were only 70 billionths of a second apart—in other words, at a frame rate per second that is almost 600 million times higher than in motion pictures.

When the researchers observed squares with a side length of five microns, they saw a very peculiar magnetic substructure: suddenly, a tiny black Batman logo appeared on a white background owing to the effects of the diffraction and interference of the laser light—in a nutshell, the interplay between the light and the micro-squares. More laser light was absorbed in some areas of the squares than others, which is why the magnetic switching only took place there. "We have discovered a fascinating interaction," sums up Nolting.

Thus, differently shaped magnets could be used to create other figures than the Batman logo. Consequently, not only could every minuscule magnet be used as an individual, writable computer bit, but even only part of one. "This could be the way to store even more data on even smaller hard drives one day," says Loïc Le Guyader, who was also involved in the PSI experiments, and is now working at the Helmholtz-Zentrum Berlin.

SOURCE: Paul Scherrer Institute; http://www.psi.ch/media/batman-lights-the-way-to-compact-data-storage

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.