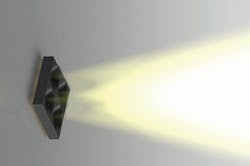

Semiconductor and solid-state lighting products manufacturer Plessey Semiconductors (Plymouth, England) developed a patented technology for Chip Scale Optics (CSO) based on its gallium nitride (GaN)-on-Silicon MaGIC light-emitting diodes (LEDs). The chip-scale design permits design of light emission angles down to ten degrees direct from the LED.

RELATED ARTICLE: Luminaire LEDs see continued efficacy gains, yet substantial market pressures exist

Plessey says that having the primary optics on the chip eliminates the cost of primary optics typically found in packaged LEDs and chip-on-board modules. Furthermore, it significantly lowers the cost and provides for far greater design freedom for secondary optics within a GaN-on-Si luminaire. The first applications will include retail spot lighting, hospitality lighting, high and low bays, street lighting, and stadium lighting. It is estimated that Plessey's CSO process will halve the cost of these lighting applications.

Keith Strickland, Plessey's CTO, said, "The CSO technology was originally designed as an on-chip phosphor dam. We realised that the original growth silicon, normally sacrificed during LED production, could be shaped and used to form mechanically robust, MEMS-type features on the emitting surface of a vertical LED. The degree of collimation is controlled in part by the mechanical dimensions of these on chip structures and we have demonstrated emission angles as low as 10 degrees. The IC industry has used silicon for over 60 years and [it] can be readily fashioned into many shapes and patterns. We have created silicon MEMS features in a variety of other applications and can manage to incorporate a complex primary optical design on the chip."

Samir Mezouari, Plessey's principal optical designer, added, "High-end lighting designers do not count lumens per Watt as the primary figure of merit for LEDs. A lighting designer aims to illuminate a particular surface area. Chip Scale Optics can significantly simplify luminaire designs by forming symmetrically collimated beams with narrow angles or asymmetric beams to form elongated far field light profiles. Schemes to collimate monochromatic light at the LED level have been developed before but no-one has previously collimated white light at the LED level."

SOURCE: Plessey Semiconductors; http://www.plesseysemiconductors.com/news-plessey-semiconductors.php

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.