Diamond Raman laser has intrinsically stable single-longitudinal-mode output

A study by researchers at Macquarie University (Sydney, Australia) has led to a new way to make ultrastable narrow-linewidth lasers that avoids spatial hole burning, which is the problem ordinarily responsible for destabilizing and broadening a laser’s frequency.1 The results are hoped to enable the next generation of lasers required for atomic clocks, remote sensing of greenhouse gases, and atom trapping, as well as in gravitational-wave astronomy.

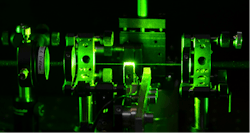

The laser was based on the diamond Raman laser technology developed at Macquarie University and reported in 2008. Using a low-birefringence single-crystal diamond made by Element Six (Ascot, England), Oliver Lux and Rich Mildren demonstrated stable single-frequency operation using a simple laser-cavity design that would normally be highly susceptible to destabilization. In particular, they placed the diamond, which was 8 × 4 × 1.2 mm in size, at the midpoint of a long standing-wave cavity, a configuration normally considered a “worst-case scenario” for inducing the instabilities that cause polychromatic behavior to occur.

80 MHz stability

The laser’s stability was on the order of 80 MHz over periods of about a minute for a 1.2 W output power (and 20 GHz for a 10 W output due to mode-hopping and multimode operation at the higher power). The single-mode laser’s wavelength could be tuned from 1238.1 to 1241.9 nm by varying the pump laser’s wavelength.

“Lasers are often thought of as being highly monochromatic, that is, of a single frequency, but in most cases their spectral purity is corrupted by a destabilizing effect referred to as spatial-hole burning. This effect causes the laser frequency to chaotically jump between a grouping of many closely spaced lines,” says Associate Professor Mildren. “The problem is avoided in our case by using a light-amplifying medium that relies on stimulated scattering rather than an excited medium that contains energy such as a population inversion.”

He adds, “Our finding provides greater freedoms for laser design and potentially much simpler, more robust systems. And, since the light-amplifier engine works using a fundamentally different principle to most lasers we are familiar with, a completely different range of materials may be used including those with extraordinary properties such as diamond. This promises a method of generating single-frequency lasers over a wider choice of wavelengths and with potentially very high power.”

REFERENCE:

1. O. Lux et al., Optica (2016); doi: 10.1364/OPTICA.3.000876

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.