Whispering-gallery resonator generates CW fourth-harmonic UV light

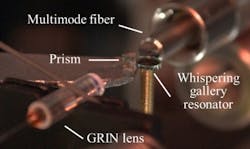

Ann Arbor, MI--When only 200 mW of IR light is coupled into a millimeter-scale whispering gallery resonator made of lithium niobate, it can produce cascaded-harmonic generation up to the fourth harmonic, serving as a compact, low-power source of UV light.1 The device, developed by researchers at the University of Michigan, could become part of future microscopes, information-storage systems, and chemical-analysis instruments.

The research was led by Mona Jarrahi and Tal Carmon, assistant professors in the Department of Electrical Engineering and Computer Science. The experiment was performed by Jeremy Moore and Matthew Tomes, both graduate students in the same department.

The resonator takes its IR input from relatively cheap telecommunications-compatible lasers. "We optimized the structure to achieve high gain over a broad range of optical wavelengths," says Jarrahi. "This allows us to make low-cost, wavelength-tunable ultraviolet sources using low IR power levels."

Lasers get progressively more difficult to generate and more inefficient, as engineers aim for shorter wavelengths, say the researchers. "As we go from green to blue, the efficiency of the laser goes down. Going to UV lasers is even harder," notes Jarrahi. "This principle was first suggested by Einstein and is the reason why green laser pointers do not actually contain a green laser. It is actually a red laser and its wavelength is divided by two to become green light."

The nonlinear-crystal resonator has variable poling and a resonator quality (Q) factor of 107.

REFERENCE:

1. Jeremy Moore et al., Optics Express, Vol. 19, No. 24, p. 24139 (2011).

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.