1.3 µm quantum-dot laser emits at temperatures exceeding 200°C

Kanagawa and Tokyo, Japan--Scientists at QD Laser, Fujitsu Laboratories Limited, and the Institute for Nano Quantum Information Electronics, the University of Tokyo have created what they say is the world's first 1.3-µm-emitting semiconductor laser that operates at temperatures over 200°C (previous semiconductor lasers have been limited to temperatures no higher than 175°C). With quantum dots as the active material, these new lasers could find use in oil and gas exploration, where temperatures often far exceed the boiling point of water.

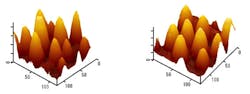

Working high-temperature quantum-dot lasers require a high density and uniformity of quantum dots. Along with acheving this, the researchers also improved quantum-dot manufacturing technology, reducing the degree of quantum-dot dispersion and enhancing uniformity up to a density of 60 billion dots per cm2 (see figure). Eight layers of these high-density and uniform quantum dots were stacked to create the laser. Under rigorous test conditions, the researchers confirmed that these lasers could emit at temperatures of up to 220°C; more than 2 mW of optical output was obtained at 200°C.

QD Laser (Tokyo, Japan) will commercialize these lasers.

QD Laser is exhibiting the new lasers at Laser World of Photonics in Munich, Germany (Booth # B1-310), held May 23–26, 2011. Details of the technology are being presented at the European Conference on Lasers and Electro-Optics and the Quantum Electronics and Laser Science Conference (CLEO/Europe--EQEC 2011), held from May 22, 2011 in Munich.

A portion of this research was funded by the Special Coordination Funds for Promoting Science and Technology MEXT (Ministry of Education, Culture, Sports, Science and Technology).

Subscribe now to Laser Focus World magazine; it’s free

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.