Osram InGaN and InGaN-plus-phosphor LEDs achieve highest-yet efficacies in green

Two types of indium gallium nitride (InGaN) LED created by Osram Opto Semiconductors (Regensburg, Germany) have achieved the highest luminous efficacies (measured in lumens per watt) yet, according to the company. One type, with green emission based on the composition of InGaN itself, achieves an efficacy of 147 lm/W at a wavelength of 530 nm and a spectral width of 35 nm. A second type, which uses a blue-emitting InGaN LED plus a green phosphor, has a luminous efficacy exceeding 200 lm/W.

The technology is a result of the “Hi-Q-LED” project, coordinated by Osram Opto Semiconductors and funded by Germany’s Federal Ministry of Education and Research (BMBF).

Conventionally, LEDs have had considerable efficacy and optical efficiency problems in the green spectral region: InGaN LEDs emitting in the blue and UV have fewer lattice defects and higher quantum efficiencies and as a result are much more efficient than those in the green (green LEDs also tend to have the shortest lifetimes of all visible LEDs); this is called the "green gap."

All-InGaN LED closes the green gap

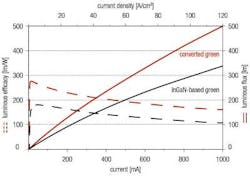

Osram's all-InGaN narrowband green LED achieves its efficacy of 147 lm/W using a chip size of 1 mm² and a driving current of 350 mA (current density: 45 A/cm²). The LED has a central wavelength of 530 nm and a forward voltage of 2.93 V at this current density. A reduction of the carrier density in the light-emitting layers and a significantly improved material quality were the key factors behind this breakthrough, says Osram.

This LED prototype shows significantly improved performance at higher current densities and achieves as much as 338 lm at 125 A/cm², although at a lower efficacy. Uses for this narrowband, high-color-purity source include projection displays.

Green full-conversion phosphor LED

The second approach comes into play in cases where the spectral bandwidth of the LED is not critical. Demonstrated efficacy for the phosphor-based green LED was 209 lm/W (at 210 lm) with a chip size of 1mm², a central wavelength of 540 nm, a forward voltage of 2.88 V, and a driving current of 350 mA (current density: 45 A/cm²). At a current density of 125 A/cm², the light output reached above 500 lm; even at this high current density, the efficacy of these devices reached 160 lm/W. The efficacy peak is at a much lower current density of 1.5 A/cm² with a maximum of 274 lm/W.

“Continuous improvement of the blue LED chips, an optimized excitation wavelength, and an increased degree of conversion of the phosphor converter are the winning combination underlying this new record-breaking LED,” says Thomas Lehnhardt, a research engineer at Osram.

Further time will be needed to develop products based on the research findings, says Osram.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.