OSRAM unveils direct-emission green laser diodes emitting at wavelengths from 510 to 530 nm

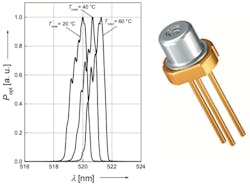

Indium gallium nitride (InGaN)-based laser diodes are straightforward to fabricate in blue-emitting versions, but are more difficult to make so that they emit in green—especially the longer-wavelength green that humans perceive as true green: early green laser diodes have typically had a slight cyan cast. OSRAM Opto Semiconductors (Regensburg, Germany), which was a commercial pioneer in the introduction of green-emitting InGaN laser diodes, has been pushing the long-wavelength boundary and has now introduced InGaN-based direct emission green laser diodes with wavelengths from 510 to 530 nm for picoprojection and other red-green-blue (RGB) or green laser applications. (OSRAM also make blue laser diodes.)

The 510 to 530 nm range encompasses "true green."

Mounted in a TO38icut or TO56 package (these are quite small, with flange diameter of 3.8 mm) with integrated photodiode, these lasers have a typical divergence angle of 7° parallel and 22° perpendicular, small enough for circularization and collimation with relatively simple optics. This is an important property for micro-electro-mechanical systems (MEMS)-based projectors in which the color components per pixel result from the emission time of the laser diode, says OSRAM.

Existing small green-laser competition comes mainly in the form of frequency-doubled diode-pumped solid-state (DPSS) lasers of the form commonly found in the first green laser pointers. These lasers are relatively complicated, containing an infrared pump laser diode to pump the solid-state laser, and a nonlinear optical crystal to frequency double the resulting IR light into the green. In comparison, a direct-emission laser diode contains only—well, a direct-emission laser diode.

Two of OSRAM's green laser-diode models, PL 520B & PL 520, have slightly different wavelength ranges at power levels of 30 mW or 50 mW at 25°C. The single-mode PL 520 laser diode has an output wavelength of 515 to 530 nm, an optical output is 50 mW and an efficiency typically of 5% to 6% at present, says OSRAM. The lasers have an operating temperature range of up to 85° C without active cooling.

Direct-emission green laser diodes can help enable practical high-power embedded projectors and could lead to the end of frequency-doubled DPSS lasers in small projectors. The lasers are also useful for laser light shows, as their high beam quality enables extremely fine structures to be displayed at a considerable distance, says OSRAM. The projectors also benefit from the high thermal stability and small size of the laser diodes. When used in point- or line-projecting lasers used, for example, in distance meters by builders, farther distances are possible because green light is far more visible than red at the same optical power.

Source: OSRAM Opto Semiconductors

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.