Nanoparticles allow liquid to flow in the direction of a laser beam

Jiming Bao and colleagues at the University of Houston in Texas say they have discovered an entirely new optofluidics process that makes it possible to use a laser beam to create a tightly focused stream of liquid within a large liquid volume. The technique has widespread applications in microfluidics, biochemistry, microfabrication, and any process that depends on lab-on-chip technology.

RELATED ARTICLE: FRET optofluidic microlasers enhance biological sensing

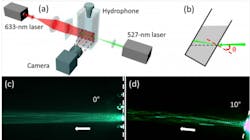

Laser light does not usually interact with water and is transmitted only at certain wavelengths, except at an interface with another medium, such as air. Photons can "push" against such an interface, although the momentum transfer is small and certainly too weak to drive fluid flow. However, Bao and his team found they could generate a stream of water inside a bigger volume of water if it contained gold nanoparticles. They shined a pulsed green laser through the glass wall of the container and, after a few minutes, observed a current of liquid flowing rapidly along the direction of the beam.

"The flows appear as liquid analogues of laser beams and move in the same directions of the refracted beams as if they are directly driven by photons of laser beams," say Bao. "We call this phenomenon laser streaming."

It turns out that the nanoparticles significantly absorb green light, which is close to the resonant frequency of the electrons they contain. This causes the particles to heat up and cool down with each pulse of light, expanding and contracting in the process. That generates acoustic waves in the water. This kind of ultrasound has long been known to move liquid in a process called acoustic streaming.

But ultrasound by itself doesn't guarantee liquid motion. So something else must be going on. Bao and co say the heating and cooling of nanoparticles near the container wall causes them to bond with the glass. Over time, the nanoparticles become encrusted around the point where the laser enters the liquid and this creates a kind of nanocavity on the glass.

The nanocavity is the key to this phenomenon. By wondrous coincidence, the cavity is just the right size and shape to focus the ultrasound being generated by the encrusted nanoparticles. In other words, the cavity becomes a resonant chamber--a loudspeaker--that generates a beam of ultrasound. Bao says the liquid stream is driven by this focused, directional ultrasound.

The ability to move liquids on a microscopic scale is crucial for all kinds of lab-on-a-chip experiments. It is also useful for nanofabrication and even for laser propulsion. Bao and his colleagues are optimistic about the future. "Laser streaming will find applications in optically controlled or activated devices such as microfluidics, laser propulsion, laser surgery and cleaning, mass transport or mixing, to name just a few," they say.

SOURCE: MIT Technology Review; https://www.technologyreview.com/s/608737/engineers-turn-a-laser-beam-into-a-stream-of-liquid/

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.