Ultrastable lasers from Northrop Grumman improve SLAC laser output

Northrop Grumman Cutting Edge Optronics (CEO; St. Charles, MO) recently delivered high energy DPSS Nd:YLF laser modules to the Department of Energy's SLAC National Accelerator Laboratory in support of the Matter in Extreme Conditions (MEC) instrument upgrade at the Linac Coherent Light Source (LCLS) facility (Menlo Park, CA). The laser modules were used in a newly designed diode-pumped front-end that helped contribute to the instrument’s 3X energy increase and optical laser pulse refinement.

RELATED ARTICLE: Upgraded 200 TW laser at SLAC synchronizes with x-ray laser for research

CEO laser engineers assisted Marc Welch, a MEC laser engineer, with the design of the single- and double-passed amplifier sections of the laser, which were then further amplified downstream. MEC scientists also built an automated system for precise pulse shaping of the laser pulses, enabling users' greater flexibility and control over the pulse shapes used in their experiments. The rock solid stability of CEO's PowerPulse[trademarked] laser modules, along with CEO's internally-designed and manufactured eDrive[trademarked] laser diode control electronics contributed to the improvement in the overall stability of MEC's high-energy laser system.

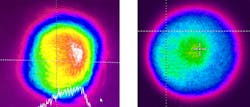

The SLAC-built, new DPSS front end utilizes CEO’s Nd:YLF modules and enables significant improvement to the laser’s spatial profile, going from ± 10% fluctuations in pulse energy when it used flash-lamp pumped Nd:YAG modules to a smooth spatial profile with better than ± 2% pulse energy stability. SLAC previously had to shape the amplified pulses using a manual, shot-to-shot iterative process. With such gross energy fluctuations from one pulse to the next, it made this 'trial and error' process even more challenging. Using DPSS laser modules with their inherent stability allowed SLAC to take full advantage of their new automated temporal pulse shaping and fulfill users’ requests for custom pulses practically 'on the fly'.

"Our work assisting the MEC instrument upgrade is indicative of the work we do every day at CEO," Says Donna Berns, Technical Sales Manager at CEO. "The foundation of our business has been built on working closely with clients to provide them with long lasting solutions to their technical issues," Berns continues. "In the case of the MEC instrument upgrade, we were able to provide technical support and transition the front end of the laser from flash-lamp technology to a higher energy and more stable DPSS platform. The upgrade will allow researchers to explore unsolved questions in fusion energy, plasma physics and materials science through more intense-pressure experimental conditions. It is exciting to imagine the discoveries this instrument will help produce."

SOURCE: Northrop Grumman Cutting Edge Optronics; http://cuttingedgeoptronics.com/2017/11/15/ceo-supports-slacs-matter-extreme-conditions-instrument-upgrade/?utm_source=General+Interest&utm_campaign=5242f6a846-SLAC+%2F+Ultrafast+Pump+-+December+2017&utm_medium=email&utm_term=0_994697b29f-5242f6a846-79508741

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.