Satya Gollapudi, Sivam Seetharam, and Thangarajah Sivapokaran

Flexibility and capabilities are expanded

FIGURE 1. 2D and 2.5D structures produced on brass and cutting tools: a) a deep engraved elevator button on brass, and b) conical and c) step shape engraving on hardened metal tools.

a (above) a deep engraved elevator button on brass

There is a significant difference between deep engraving and the standard marking process in terms of depth and dimension (2.5D, 3D). In most cases, marking generates a color change due to heat or pigments present inside the material. If a surface is etched to a depth of < 0.001 in., it can be considered as marking. On the other hand, deep engraving removes the bulk of the material by evaporation. In general, a depth of more than 0.003 in. can be defined as deep engraving.

c) step shape engraving on hardened metal tools

When selecting a laser deep engraving system, it is important to remember that the laser source is only one component of the system. A comprehensive deep engraving software package with the key features described in this article plays a large role in the laser deep engraving process.

Model generation

Standard laser marking software programs allow users to create and load objects such as text, barcode, logos, and images. Software designed specifically for deep engraving takes this a step further by enabling users to build 2.5D models by specifying the necessary parameters.

2.5D objects are created by giving vertical projection to a 2D object. Using deep engraving software, a user can generate a 2.5D object from a 2D image by specifying the required depth. In addition to the vertical projection, the user can project 2D shapes into symmetrical transformations, such as tapered, cylindrical, and step shapes. This feature is very useful when generating many of the present day industrial engraving requirements. See FIGURE 1 for examples of a deep engraved elevator button on brass, and conical and step shape engraving on hardened metal tools.

Layering

Once a 2.5D or 3D model is generated, it is ready for layering, which involves slicing the entire object in theFIGURE 2. Schematic diagram of layering and filling used in objects.

Filling is an important feature of deep engraving software that allows users to produce various styles to suit the engraving needs. Line filling is frequently used with various styles, angles (unidirectional, double, serpentine, etc), and density. By varying the angle, users can produce smooth and non-overlapping surfaces. Other filling styles such as helix and offset are available and yield reasonable quality with improved cycle time. Users can adjust these features to achieve the right quality, depth, and surface finish.

In addition, users can either define the processing parameters for the entire object or they can specify them individually for each layer. This feature is useful in case of composite/meta materials where the ablation threshold is different for each material or to achieve desired surface finishes.

FIGURE 3. 3D vector file engraved on brass.

3D file import

In addition to loading and building models, users should be able to import 3D vector/raster files created in other 3D applications. A deep engraving software package should support most of the 3D vector files available in the market such as *.dwg , *.dxf, *.stl, *.rlf, *.X, and *.lsc. FIGURE 3 shows a 3D vector file engraved on brass.

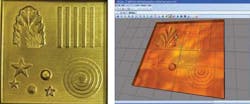

FIGURE 4. Digitized raster image engraved on copper, with all three stages of this process using the XLCAM deep engraving software package with the final results above.

The software should also be compatible with digitized raster files (such as *.bmp,*.tif) that have height information stored as varying gradients from black to white; another nice feature to have is the capability to view these files under different lighting conditions to see the details of the objects. These files can be used to build a model to specific dimensions without losing resolution. FIGURE 4 shows all three stages of this process, (using the XLCAM deep engraving software package developed by Quantronix Corp.), from the imported raster file, to the generated model, to the final engraving results.

Integration with external devices

Precise engraving is a combination of high resolution images, proper layering, and the correct laser source. Some deep engraving applications may require additional external devices to achieve the desired results. Therefore, it is vital that a deep engraving software package has the capability to communicate with external devices such as X-Y-Z stages, programmable apertures, I/O devices, and camera systems.

For example, for engravings deeper than 1-2 mm, the software should communicate with a Z stage after each engraving layer to keep the laser in focus. The resolution of the movement depends on the details of the engraving. During mass production, automation can be achieved with I/O signals for part sensing/completion of engraving. In some instances, users can combine conventional tooling methods with a laser system to achieve the optimal cycle time, as tooling will remove the bulk of the material and the laser can engrave the fine details. Another exciting development in mass production is the use of lasers on flexible robotic arms, enabling deep engraving access to larger areas and to surfaces that are not easily accessible.

In short, when selecting a laser deep engraving system, it can be easy to only focus on the laser source. A comprehensive software package with key features can provide flexibility and expand the possibilities of the laser deep engraving process.

Satya Gollapudi ([email protected]) is an applications engineer, Sivam Seetharam is team leader, Industrial Software Solutions, and Thangarajah Sivapokaran is director, Laser Marking Systems, at Quantronix Corp., East Setauket, New York.

Past ILS Issues