In Depth Look at Anti-Reflection Coatings

Coating Theory | Coating Specifications

Edmund Optics offers all TECHSPEC® transmissive optics with a variety of anti-reflection (AR) coating options that vastly improve the efficiency of the optic by increasing transmission, enhancing contrast, and eliminating ghost images. Most AR coatings are also very durable, with resistance to both physical and environmental damage. For these reasons, the vast majority of transmissive optics include some form of anti-reflection coating. When specifying an AR coating to suit your specific application, you must first be fully aware of the full spectral range of your system. While an AR coating can significantly improve the performance of an optical system, using the coating at wavelengths outside the design wavelength range could potentially decrease the performance of the system.

COATING THEORY

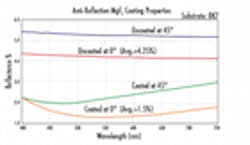

Figure 1: MgF2 Anti-Reflection Coating Performance

Why Choose an Anti-Reflection Coating?

As light passes through an uncoated glass substrate, approximately 4% will be reflected at each interface. This results in a total transmission of only 92% of the incident light. Applying an AR coating on each surface will increase the throughput of the system and reduce hazards caused by reflections traveling backwards through the system (ghost images). Anti-reflection coatings are especially important if the system contains many transmitting optical elements. Also, many low-light systems incorporate AR coated optics to allow for efficient use of light. Figure 1 demonstrates the difference between an uncoated and coated single surface BK7 substrate. The coating used is a λ/4 of MgF2 centered at 550nm.

Figure 2: Illustration of Light Interacting with Thin Film

How Does an Anti-Reflection Coating Work?

The transmission properties of a coating are dependent upon the wavelength of light being used, the substrate's index of refraction, the index of refraction of the coating, the thickness of the coating, and the angle of the incident light.

The coating is designed so that the relative phase shift between the beam reflected at the upper and lower boundary of the thin film is 180°. Destructive interference between the two reflected beams occurs, cancelling both beams before they exit the surface. The optical thickness of the coating must be an odd number of quarter wavelengths (λ/4, where λ is the design wavelength or wavelength being optimized for peak performance), in order to achieve the desired path difference of one half wavelength between the reflected beams, which leads to their cancellation.

The equation for determining the index of refraction of the thin film needed for complete cancellation of the two beams is:

nf is the index of refraction of the thin film

n0 is the index of refraction of air (or the incident material)

ns is the index of refraction of the substrate

COATING SPECIFICATIONS

Anti-Reflection Coating Options

Edmund Optics offers all TECHSPEC® lenses with an optional single-layer, dielectric anti-reflection (AR) coating to reduce surface reflections. In addition, custom single-layer, multi-layer, V, and 2V coatings are available for both our off-the-shelf and large volume custom orders. View Custom Optical Lens Coatings for information.

Figure 3: Wavelength Selection Chart

λ/4 MgF2: The simplest AR coating used is λ/4 MgF2 centered at 550nm (with an index of refraction of 1.38 at 550nm). MgF2 coating is ideal for broadband use though it gives varied results depending upon the glass type involved.

VIS 0° and VIS 45°: VIS 0° (for 0° angle of incidence) and VIS 45° (for 45° angle of incidence) provide optimized transmission for 425 – 675nm, reducing average reflection to 0.4% and 0.75% respectively. VIS 0° AR coating is preferred over MgF2 for visible applications.

VIS-NIR: Our visible/near-infrared broadband anti-reflection coating is specially optimized to yield maximum transmission (>99%) in the near infrared.

Telecom-NIR: Our telecom/near-infrared is a specialized broadband AR coatings for popular telecommunications wavelengths from 1200 – 1600nm.

UV-AR and UV-VIS: Ultraviolet coatings are applied to our UV fused silica lenses and UV fused silica windows to increase their coating performance in the ultraviolet region.

NIR I and NIR II: Our near-infrared I and near-infrared II broadband AR coatings offer exceptional performance in near-infrared wavelengths of common fiber optics, laser diode modules and LED lights.

SWIR: Our Short-Wave Infrared (SWIR) broadband anti-reflection coating is designed for maximum transmission of wavelengths from 900 – 1700nm for common SWIR applications including electronics or solar cell inspection, surveillance, or anti-counterfeiting.

Standard Broadband Anti-Reflection Coating Information* | |||

Name | Wavelength Range | Reflection Specifications | Typical Energy Density Limit |

MgF2(View Curve) | λ/4 @ 550nm | Ravg ≤ 1.75% 400 - 700nm (N-BK7) | 10 J/cm2 @ 532nm, 10ns |

UV-AR (View Curve) | 250 - 425nm | Rabs ≤ 1.0% 250 - 425nm | 3 J/cm2 @ 355nm, 10ns |

Ravg ≤ 0.75% 250 - 425nm | |||

Ravg ≤ 0.5% 370 - 420nm | |||

UV-VIS (View Curve) | 250 - 700nm | Rabs ≤ 1.0% 350 - 450nm | 3 J/cm2 @ 355nm, 10ns |

Ravg ≤ 1.5% 250 - 700nm | 5 J/cm2 @ 532nm, 10ns | ||

VIS-EXT (View Curve) | 350 - 700nm | Ravg < 0.5% 350 - 700nm | – |

VIS-NIR (View Curve) | 400 - 1000nm | Rabs ≤ 0.25% 880nm | 5 J/cm2 @ 532nm, 10ns |

Ravg ≤ 1.25% 400 - 870nm | |||

Ravg ≤ 1.25% 890 - 1000nm | |||

VIS 0° (View Curve) | 425 - 675nm | Ravg ≤ 0.4% 425 - 675nm | 5 J/cm2 @ 532nm, 10ns |

VIS 45° | 425 - 675nm | Ravg ≤ 0.75% 425 - 675nm | 5 J/cm2 @ 532nm, 10ns |

YAG-BBAR (View Curve) | 500 - 1100nm | Rabs < 0.25% 532nm | – |

Rabs < 0.25% 1064nm | |||

Ravg < 1.0% 500 - 1100nm | |||

NIR I (View Curve) | 600 - 1050nm | Ravg ≤ 0.5% 600 - 1050nm | 7 J/cm2 @ 1064nm, 10ns |

NIR II (View Curve) | 750 - 1550nm | Rabs ≤ 1.5% 750 - 800nm | 8 J/cm2 @ 1064nm, 10ns |

Rabs ≤ 1.0% 800 - 1550nm | |||

Ravg ≤ 0.7% 750 - 1550nm | |||

Telecom-NIR | 1200 - 1600nm | Rabs ≤ 0.25% 1295 - 1325nm | – |

Rabs ≤ 0.25% 1535 - 1565nm | |||

Ravg ≤ 0.25% 1200 - 1600nm | |||

SWIR (View Curve) | 900 - 1700nm | Rabs ≤ 1.5% 900 - 1700nm | – |

Ravg ≤ 1.0% 900 - 1700nm | |||

*Note: Ravg = Average Reflectance, Rabs = Absolute Reflectance.

About Sponsor

Edmund Optics is a leading supplier of optics and optical components, designing and manufacturing a wide array of multi-element lenses, lens coatings, imaging systems, and opto-mechanical equipment. EO’s state of the art manufacturing capabilities combined with its global distribution network has earned it the position of the world’s largest supplier of off-the-shelf optical components. Customers can purchase items by calling 1-800-363-1992, via the catalog or the website at http://www.edmundoptics.com/