Nearly every major player in the autonomous vehicles market is incorporating lidar into its vehicles. Many believe lidar is the most important optical technology in the race toward mainstream self-driving cars.

Solid-state lidar solves industry challenges

Most of the innovation of lidar systems in the automotive industry is focused on creating solid-state systems and reducing the movement of the mechanism that scans the laser beam across the field of view. Because they don’t have mechanical mirrors with 360-degree movement, this typically results in a more limited field of view. But the new solid-state lidar systems meet the technical requirements for long-distance scanning—and because there are no moving parts, they’re also more durable and less expensive than the previously used mechanical scanning systems that were sensitive to vibration.

With optical phased arrays (OPA) lidar systems, the best field of view commercially available is about 50 degrees, and micro-electrical-mechanical systems (MEMS) lidar systems are only marginally better at about 60 degrees. Therefore, at least six solid-state lidar systems will be needed to replace one spinning rooftop lidar system. So, for solid-state lidar systems to be commercially viable, the price of multiple solid-state lidar systems must be better than that of a single spinning lidar system.

The intricacies of designing solid-state lidar systems

In addition to increasing the field of view, optical designers are working to maximize the range of automotive lidar systems. The maximum range of the lidar system depends on the laser power, the reflectivity of the target object, and the detector sensitivity.

Lidar systems must also take eye safety into account. Most carmakers strive to use Class 1 lasers, which “cannot emit laser radiation at known hazard levels,” according to the Occupational Safety and Health Administration (OSHA). Therefore, the detector must be sensitive enough to work with both eye-safe laser emissions as well as low-reflectivity targets.

The detectors must also function in bright daylight and handle ambient light levels as high as 98,000 lux (lumens per square meter). To help meet this requirement, lidar designs utilize narrow bandpass filters that only accept wavelengths close to laser light, or they restrict the angle of view.

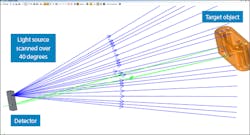

An OpticStudio model showing a light source scanned over 40 degrees toward target object. A small fraction of the source rays are reflected off the target object and collected by the detector.

Virtual prototyping gets lidar systems to market faster

While designing the intended behavior of optical systems can be straightforward, predicting the as-built behavior and balancing performance with cost requires a comprehensive virtual prototype. All the possible sources of stray light around the lidar systems in autonomous vehicles should be considered. For example, stray sunlight in a lidar system can be treated as a false signal. Or, the signal in a neighboring lidar system may be another source of stray light.

Zemax Virtual Prototyping is the only solution to create a working virtual prototype of the entire lidar system, not just the optical or mechanical components alone. Engineering teams can simulate optical performance on the entire optomechanical product before creating a physical prototype. With Zemax Virtual Prototyping, you can include the effect of traffic signals turning on and off, bicycle lights, and other stray sources.

Nearly every major player in the autonomous vehicles market is incorporating lidar into its vehicles. Many believe lidar is the most important optical technology in the race toward mainstream self-driving cars.

Solid-state lidar solves industry challenges

Most of the innovation of lidar systems in the automotive industry is focused on creating solid-state systems and reducing the movement of the mechanism that scans the laser beam across the field of view. Because they don’t have mechanical mirrors with 360-degree movement, this typically results in a more limited field of view. But the new solid-state lidar systems meet the technical requirements for long-distance scanning—and because there are no moving parts, they’re also more durable and less expensive than the previously used mechanical scanning systems that were sensitive to vibration.

With optical phased arrays (OPA) lidar systems, the best field of view commercially available is about 50 degrees, and micro-electrical-mechanical systems (MEMS) lidar systems are only marginally better at about 60 degrees. Therefore, at least six solid-state lidar systems will be needed to replace one spinning rooftop lidar system. So, for solid-state lidar systems to be commercially viable, the price of multiple solid-state lidar systems must be better than that of a single spinning lidar system.

The intricacies of designing solid-state lidar systems

In addition to increasing the field of view, optical designers are working to maximize the range of automotive lidar systems. The maximum range of the lidar system depends on the laser power, the reflectivity of the target object, and the detector sensitivity.

Lidar systems must also take eye safety into account. Most carmakers strive to use Class 1 lasers, which “cannot emit laser radiation at known hazard levels,” according to the Occupational Safety and Health Administration (OSHA). Therefore, the detector must be sensitive enough to work with both eye-safe laser emissions as well as low-reflectivity targets.

The detectors must also function in bright daylight and handle ambient light levels as high as 98,000 lux (lumens per square meter). To help meet this requirement, lidar designs utilize narrow bandpass filters that only accept wavelengths close to laser light, or they restrict the angle of view.

An OpticStudio model showing a light source scanned over 40 degrees toward target object. A small fraction of the source rays are reflected off the target object and collected by the detector.

Virtual prototyping gets lidar systems to market faster

While designing the intended behavior of optical systems can be straightforward, predicting the as-built behavior and balancing performance with cost requires a comprehensive virtual prototype. All the possible sources of stray light around the lidar systems in autonomous vehicles should be considered. For example, stray sunlight in a lidar system can be treated as a false signal. Or, the signal in a neighboring lidar system may be another source of stray light.

Zemax Virtual Prototyping is the only solution to create a working virtual prototype of the entire lidar system, not just the optical or mechanical components alone. Engineering teams can simulate optical performance on the entire optomechanical product before creating a physical prototype. With Zemax Virtual Prototyping, you can include the effect of traffic signals turning on and off, bicycle lights, and other stray sources.

Free eGuide

Lidar is one of the most important optical technologies in the race toward mainstream self-driving cars. Most of the innovation of lidar systems in the automotive industry is focused on creating solid-state systems and reducing the movement of the mechanism that scans the laser beam across the field of view. Download a free eGuide learnabout:

- The latest designs for solid-state lidar, including a phased array

- The intricacies of designing solid-state lidar systems, including field of view, range, and eye safety

- Using virtual prototypes to predict the as-built behavior and balance performance with cost