At LASER World of Photonics, Nanoscribe launches Quantum X for microoptics fabrication

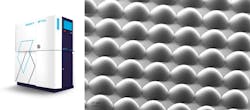

Nanoscribe (Eggenstein-Leopoldshafen, Germany) has launched an additive-manufacturing-based microlens-array fabricating machine called the Quantum X at the international trade fair LASER World of Photonics in Munich, Germany (Jun 24 to 27, 2019). Nanoscribe says the Quantum X "adds to [Nanoscribe's] portfolio of high-resolution additive manufacturing systems for the nano- and microscale with a new device specially designed for maskless lithography of highly-precise microoptics."

At LASER World of Photonics, the show's Innovation Award for the most innovative product was presented to Nanoscribe for the Quantum X maskless lithography system. The prize was sponsored by the trade fair and the British specialist publisher Europa Science.

The Quantum X is the world’s first industrial system based on two-photon grayscale lithography (2GL), the patent-pending technology developed by Nanoscribe, says the company. 2GL combines gray-scale lithography with Nanoscribe's two-photon polymerization technology, allowing prototypes of refractive and diffractive micro-optics as well as polymer masters to be produced.

The system has three live-view cameras for process control and a resin dispenser. To simplify the changeover between hardware configurations, objective and sample holder recognition run automatically.

Multilevel diffractive optical elements (DOEs) can be produced by modulating the laser power in one scanning plane, reducing the print time necessary for multilayer microfabrication. Nanoscribe says that refractive microoptics also benefit from the contouring capabilities achieved with 2GL processes, making single optical elements, arrays with high fill factors of up to 100%, and varying shapes such as spherical and aspherical lenses possible in a direct and maskless process.

The Quantum X software controls and monitors print jobs in real time and is operated by means of an interactive touchscreen control panel. To manage and organize users' projects, a continuous execution of a series of print jobs is supported by a job queue.

The software has a wizard that guides designers and engineers through print job creation from the beginning and accepts grayscale images of arbitrary optical designs. For example, BMP, PNG, or TIFF files of up to 32-bit resolution are accepted and prepared for direct fabrication with the Nanoscribe Quantum X.

In the machine's two-photon grayscale lithography process, laser power modulation and dynamic focus positioning are synchronized at high scanning speeds for full voxel size control along each scanning plane. Quantum X produces simple and complex optical shapes with variable feature heights within each scan field, says Nanoscribe. Discrete and accurate steps, as well as essentially quasicontinuous topographies, can be printed in one step without the need for several lithography steps or multiple mask fabrication.

Many types of substrates, including transparent and opaque ones, can be used at sizes of up to six-inch wafers. Nanoscribe provides photoresins that the company says are easy to handle and allow high aspect ratios, enable high structures, and avoid mask fabrication, spin-coating, and pre- or post-baking.

For more info, see https://www.nanoscribe.com/en/solutions/quantum-x

Source: Nanoscribe

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.