Pinhole-based ‘photon sieve’ widens viewing angle of dynamic holographic displays

Dynamic 3D holographic images can be (and are often) created and projected using a liquid-crystal-display (LCD)-based spatial light modulator (SLM). However, due to the nature of SLMs, the viewing angle of such a setup is typically limited to only a few degrees, with the viewing angle becoming narrower as the resolution is made greater.

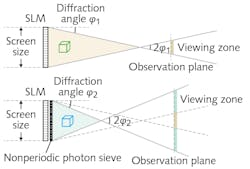

Now, researchers at the Korea Advanced Institute of Science and Technology (KAIST) have developed an ultrathin SLM-based holographic display that can project dynamic multicolored, 3D images over a wider angle.1 The system’s critical component is a thin film of titanium filled with very small nonperiodic pinholes that are precisely paired with each pixel of the SLM. The film acts as a “photon sieve”—each pinhole diffracts light emerging from itself widely, resulting in a high-definition 3D image observable from a wide angle (see figure). (Note: this is not the same type of photon sieve as those used to form lightweight telescope imaging systems.)

Widening the diffraction pattern

The entire system is very small: the researchers used a 1.8 in. off-the-shelf, liquid-crystal-based SLM panel with a resolution of 1024 × 768 pixels. The titanium film, whose substrate is attached to the back of the panel, is 300 nm thick. Each 2.2-μm-diameter pinhole in the nonperiodic pseudorandom pinhole pattern is placed on top of a different SLM pixel and is much smaller than the pixel, widening the diffraction pattern.

The pinhole pattern is completely known and does not change over time, even for dynamic holograms. The fact that the pinholes are located within pixels enables straightforward calculations without having to resort to optical transmission matrices. The technique does considerably lower the light throughput of the holographic display, though—the researchers say that future setups could use microlenses or microsized gratings instead of pinholes for increased throughput.

“Our approach suggests that holographic displays could be projected from thin devices, like a cell phone,” says YongKeun Park, a physicist at KAIST who led the research. The team demonstrated their approach by producing a hologram of a moving, tricolored cube (using lasers of three different colors as a light source).

Previous studies from Park’s group used optical diffusers for the same purpose, but the size of the device was bulky and difficult to operate, and it took a long period of time to calibrate. In the present work, the group tailored the photon sieve to demonstrate a simple, compact, and scalable method for a 3D holographic display.

The photon sieve adds almost nothing to the size and weight of the SLM-based holographic display and adds little to its manufacturing complexity, as the photon sieve unit can be easily integrated into the LCD production process. Applications could include 3D cinema viewing without the need for glasses, watching holographic videos on television, and smartphone screens.

REFERENCE

1. J. Park et al., Nat. Commun. (2019); https://doi.org/10.1038/s41467-019-09126-9.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.