Planar optics are tunable in wavefront output with speeds in milliseconds

Building an adjustable zoom lens in a millimeters-thick cell phone, in a miniaturized microscope, or at the distal end of a medical endoscope requires complex lenses that can handle the full optical spectrum and be reshaped electrically within milliseconds.

Pascal Berto of the Institut de la Vision (Paris, France) and his colleagues from the Barcelona Institute of Science and Technology (Barcelona, Spain) and Université Paris Descartes have demonstrated an adjustable technique to manipulate light without any mechanical movement, resulting in devices that the researchers call "smartlenses."1

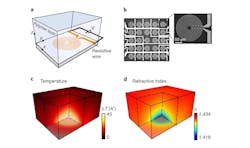

When a current is passed through a well-optimized micrometer-scale resistor, the heating locally changes the optical properties of a transparent polymer plate holding the resistor, changing the plate's refractive index. As a result, this microscale hot region is able to deviate light. Within milliseconds, a slab of polymer is turned into a lens and back: small, micrometer-scale smartlenses heat up and cool down quickly and with minimal power consumption. They can even be fabricated in arrays, and the authors show that several objects located at very different distances can be brought into focus within the same image by activating the smartlenses located in front of each of them, even if the image is in color.

Freeform corrections possible

By modeling the diffusion of heat and the propagation of light, the authors show that complex optical devices can be optimized using algorithms inspired by the laws of natural selection to go way beyond simple lenses: a properly engineered resistor can deviate light in a chosen direction, while another will refract it into a ring, or other specific shapes. If the right resistor is imprinted on it, a piece of polymer could be activated or deactivated at will to generate a given freeform optical function and, for example, correct specific defects in human eyesight, or the aberrations of an optical instrument.

Most importantly, once the thermal and optical calculations are done, imprinting masses of transparent resistors on polymers can be done at very small costs, for high-end technological systems as well as simple consumer-oriented imaging devices.

Source: http://www.institut-vision.org/en/news1/466-planar-optics.html

REFERENCE:

1. Pascal Berto et al., Nature Photonics (2019); https://doi.org/10.1038/s41566-019-0486-3.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.