Metasurface optic for Gaussian beams accepts a nonplanar input beam

With their potential ability to replace bulk-glass optical components, and even entire optical systems, metasurface optics have come a long way in their capabilities, including high-numerical-aperture (NA) operation and multispectral or broadband operation. But most metasurface optics today are designed to accept and modify plane waves, eliminating the possibility of finite-conjugate metasurface optics. Researchers at the Chalmers University of Technology (Göteborg, Sweden) and Politecnico di Torino (Turin, Italy) have now theoretically developed a metasurface, designed for use with monochromatic Gaussian beams, that reflects a diverging beam and forms a converging beam in the process (in other words, it’s the metasurface analogue of a concave spherical mirror)—the process has an efficiency of higher than 90%.

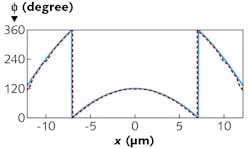

In the model, the subwavelength metasurface elements (meta-atoms) are fins of titanium dioxide (TiO2) with varying orientations (producing differing phases) in almost-periodic arrays. Both all-dielectric and hybrid metal-dielectric structures were modeled for wavelengths in the near-infrared, with most of the modeling done on the hybrid metal-dielectric version. The array period was 380 nm—the difference in phase between consecutive elements grew quadratically with the distance from the optical axis. The whole reflective metasurface had a radius of 12.57 µm and a focal length of 50 λ. The beam waist was 3.21 µm for both the incoming and reflected beams, with a close-to-ideal beam profile. An example phase profile for the ideal Gaussian field (blue line in figure) and cross-polarized reflected field (red dotted line) at a distance of 1350 nm from the surface matched well for the hybrid metal-dielectric structure. Reference: J. Martínez-Llinàs et al., Opt. Express, 27, 15 (Jul. 22, 2019); https://doi.org/10.1364/oe.27.021069.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.