Careful optical-system design enables cutting-edge high-power laser applications

VOLKER MELZER and MATTHIAS KOPPITZ

The increasing demand for high-power lasers (100 W up to kilowatts) in laser materials processing presents a technical challenge for optical components such as f-theta lenses, beam expanders, and Faraday isolators. As a result, thermally induced beam-degradation effects are playing an increasing role in a variety of high-power laser and related applications. This article provides an overview of these undesired effects and details an analysis and design process for reducing the impact that these physical effects can have on optical components used for high-power laser materials processing.

What is thermal lensing?

The most prominent artifact in high-power laser applications is thermal lensing, producing a focus shift. An intense laser beam passing through the optical glasses of an f-theta lens or the magneto-optical crystal in a Faraday isolator can locally heat the optical material. This local heating is largely dependent on the laser power density and absorption of the optical material, and causes thermally induced dispersion of the refractive index. The laser beam profile, absorption, and heat dissipation result in a transverse refractive-index gradient in the optical medium, which generates a significant refractive index difference in the center compared to the edge of the optical material, resulting in an undesired gradient-index (GRIN) lens (see Fig. 1).

Additional lensing effects that frequently occur for laser crystals, optics, and coating materials include refractive-index changes caused by thermally induced mechanical stress, as well as mechanical stress and thermal expansion leading to bulging of the end faces of the gain medium or of optical parts.

What are depolarization and photocontamination?

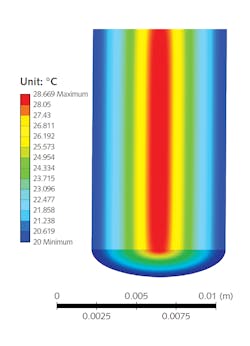

For high-power laser applications, maintenance of a high polarization-extinction ratio is often required. Deleterious effects include local heating, which can result in a gradient of temperature distribution in the optical material under high-power laser exposure (see Fig. 2), which can then lead to stress-induced birefringence in the optical material, mainly for crystalline materials like magneto-optical material. This local birefringence structure changes the polarization state of the laser light locally to random polarization and reduces the polarization-extinction ratio. The reduction in the achievable isolation is often significant for Faraday isolators.Figure 2 depicts the impact of the gradient of temperature distribution in the magneto-optical material terbium gallium garnet (TGG) used in Faraday isolators. A typical temperature difference of a few degrees can slightly change the Verdet constant locally without having much of an impact on the average polarization rotation. As a result, the impact on the isolation is significantly smaller compared to the dominant depolarization effect.

Photocontamination, also called photostimulated or laser desorption, has a significant impact on the performance of optics under high-power laser exposure. A strong electromagnetic field, local heating, and local ionization effects cause desorption of volatile organic components onto optical surfaces exposed to laser radiation.1 The desorbed organic components stick onto the optical surfaces. Due to this undesired contamination, the performance of the optical surface will degrade and can ultimately cause laser-induced damage. Therefore, it is essential to keep outgassing of parts on a very low level and to keep volatile organic components away from laser cavities and optical modules that are in the laser beam path. Typical sources for volatile organic components include adhesives and anodized surfaces.

Finding a solution: Interaction of optical design and FEA

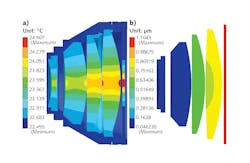

These degradation effects can be kept under control if they are taken into account during the design process. The design process should start with tests of material properties with respect to outgassing, absorption, and deformation, followed by simulations of thermal focus shift and deformation of optics. The optical-module design process should include interaction and data exchange between different in-house software tools such as optical design and finite-element-analysis (FEA) software, consisting of four main steps:

1. Input of laser-beam data and material properties into the optical-design software.

2. Calculation of introduced power due to absorption and local heating of optics by using in-house optical-design software.

3. Feeding calculated temperature-distribution data for coatings, lenses, and windows into FEA analysis software to calculate local surface deformation of these parts (see Fig. 3).

4. Transfer of mechanical deformation and local heating data back to in-house optical-design software to enable comprehensive calculation of predicted GRIN-lens structures and calculation of localized optical artifacts.The calculated estimation of the mechanical deformation of the optical elements and the formed GRIN lens structures enable precise prediction of thermal focus shift and impact on the beam quality based upon on the laser power.

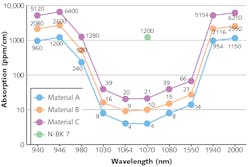

In a recent simulation of reduced absorption of the optical materials, the residual impact of remaining thermo-optical effects was analyzed. It became apparent that the impact of even very small absorption needed to be kept under control to enable design of f-theta lens assemblies best suited for high-laser power applications. It was learned that the absorption coefficient of optical glasses in the near-infrared (near-IR; 1064 nm) spectral range should be in the level of 10 ppm/cm for a typical f-theta lens design to achieve small to negligible impact of thermo-optical effects.

Transmittance of glass materials and coatings

The described design and simulation effort proved that it is essential to keep the properties of the used materials and surfaces under control, as even the purest optical glass materials and high-end antireflection (AR) coatings can have residual absorption in the range of ppm/cm.

Figure 4 shows measurements obtained by an ultralow-level absorption-measurement system that assesses absorption in the ppm/cm range. The absorption coefficient of typical optical glasses (for example, N-BK 7 glass) in the near-IR spectral range is at the level of 10,000 to 1000 ppm/cm, which is far too high for high-laser power densities. Absorption should be in the range of 10 ppm/cm or even less. Optical quartz glasses with the lowest absorption should be used for high-power laser-based materials-processing applications at 532 nm and 1064 nm wavelengths.Additionally, the significant impact of AR coatings on the overall absorption was identified. Even with an AR coating thickness of a few micrometers, the residual absorption is often in the range of 0.1% to 0.01% (1000 to 100 ppm). For a Gaussian laser beam with 1000 W average laser power and up to 20 mm beam diameter (1/e2), this causes power dissipation in a very small volume of material in the coating layer. Peak power density of such a beam is approximately 640 W/cm2.

While absorption loss in the coating layer of 0.1% of 640 W/cm2 does not sound like much, it is significant in high-power laser exposure. One can compare this to a cooking plate, which can have 1000 W electrical power at the highest heating level at a round area with a diameter of 16 cm. While the cooking plate has a power density of 1000 W/200 cm2 = 5 W/cm2, an absorbed power density of 0.64 W/cm² is only a magnitude smaller compared to the very hot cooking plate, hence significant local heating is happening. Even an absorption of 0.01% and an absorbed power density of 0.06 W/cm² can cause significant local heating by a few degrees Celsius.

This example shows that local heating and deformation of the coating layer and the glass material can result in a significant change to the optical properties of coating and surrounding glass material. As a result, it became necessary to review and improve the whole coating process; a new ultralow-absorption coating has been designed to keep coating absorption on the lowest possible level. The following were taken into account:

- Usage of coating materials of highest purity grade

- Regular comprehensive cleaning of the coating equipment

- Improved handling and cleaning of the substrates to avoid even the smallest contamination traces

- Comprehensive improvement of coating processes

- Impact of angle of incidence on the coating surfaces

New low absorption magneto-optical material

In addition to beam-guiding optics, it is also important to optimize other laser components to achieve low impact of thermo-optical artifacts. Lasers are often equipped with a Faraday isolator to protect them from back-reflection—however, Faraday isolators are not free of thermo-optical artifacts if exposed to high laser power density.

The most-used magneto-optical material, TGG, has some absorption, causing significant thermo-optical artifacts if exposed to high laser power density. To combat this, Synoptics (Charlotte, NC) recently developed a new low-absorption magneto-optical material, potassium terbium fluoride (KTF),2 which has a much smaller absorption compared to TGG, making it a better-suited magneto-optical material for high laser power levels. As a result, Excelitas is offering Faraday isolators containing this new material.

Eliminate outgassing materials and surfaces

Another long-term degradation effect is outgassing. Outgassing substances contaminate the surfaces of optical components under high-power laser exposure due to photocontamination effects. In addition to long-term outgassing of many adhesives taking place during curing, surfaces of coatings and mechanical parts also outgas volatile organic compounds. Anodized surfaces of aluminum parts are a very rich outgassing source. These surfaces are rough and porous like foam; they easily absorb solvents and liquids and thus carry many different volatile compounds.

Outgassing reduction starts the initial design stage. It can be accomplished by using low-outgassing adhesives, and by avoiding usage of surfaces that are prone to carrying volatile organic components. It is also important to clean and long-term temper all parts to remove residual volatile organic compounds.

Many high-power laser applications require specially designed f-theta lenses, beam expanders, and Faraday isolators to ensure required performance. It is important to take into account thermal lensing, depolarization, and photo-contamination effects throughout the development and manufacturing of these optical parts. By using various design tools, combined with a deep knowledge of material properties and continuous control of the materials and processes, a balanced tradeoff between performance requirements for the optical parts and maintenance of the required high-end beam quality can be achieved to ensure optimal results for high-power lasers and applications.

REFERENCES

1. A. Ikeda and K. Fukutani, “Photo-stimulated desorption,” The Surface Science Society of Japan (eds.) Compendium of Surface and Interface Analysis, Springer, Singapore (2018).

2. K. T. Stevens et al., Laser Tech. J., 13, 3, 18–21 (2016).

3. Alexander Laskin et al, "Influence of thermally induced aberrations on resulting intensity distribution", Proc. SPIE 10525, High-Power Laser Materials Processing: Applications, Diagnostics, and Systems VII, 1052506 (15 February 2018).

Volker Melzer is product manager and Matthias Koppitz is project manager, both at Qioptiq Photonics, an Excelitas Technologies company, Feldkirchen, Germany; e-mails: [email protected] and [email protected]; www.qioptiq.de.

![FIGURE 1. A schematic of optics exposed to low and high laser power [3], where refractive-index gradient and bulging are not present at low laser power (a); thermal focus shift and thermal induced spherical aberrations caused by the thermal induced refractive index gradient and lens deformation are induced at high power (b). FIGURE 1. A schematic of optics exposed to low and high laser power [3], where refractive-index gradient and bulging are not present at low laser power (a); thermal focus shift and thermal induced spherical aberrations caused by the thermal induced refractive index gradient and lens deformation are induced at high power (b).](https://img.laserfocusworld.com/files/base/ebm/lfw/image/2020/03/2003LFWmil_z01.5e68eacdde568.png?auto=format,compress&fit=fill&fill=blur&q=45?w=250&width=250)