Schott, Inkron, EVG, and WaveOptics team up to fabricate next-gen waveguides for AR and MR devices

At SPIE Photonics West (Feb, 2020; San Francisco, CA), four European companies—Schott (Mainz, Germany), Inkron (Espoo, Finland), EV Group (EVG; Florian am Inn, Austria), and WaveOptics (Abingdon-on-Thames, UK)—presented what they say are the world's first waveguides made on a glass substrate with a refractive index of 1.9 and a matching nanostructured polymer; the waveguides were produced on a 300 mm wafer platform ready for mass production.

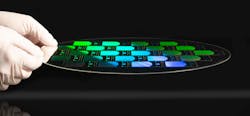

At the show, glass-products-maker Schott unveiled its RealView 1.9 high-index glass wafers, which have a refractive index of 1.9 and a diameter of 300 mm; the wafers are the basis for high-volume next-generation augmented-reality (AR) and mixed-reality (MR) waveguide manufacturing intended to drive down the cost per unit and maintain the precise standards demanded by AR and MR.

The nanotech company Inkron manufactures a resin that matches the refractive index of 1.9; this resin was used to imprint as many as 24 waveguides on a single 300 mm RealView wafer using the EVG Hercules NIL nanoimprint platform. The waveguides based on Schott and Inkron materials are patterned using the nanoimprint lithography (NIL) capabilities of EVG based on a waveguide architecture created by WaveOptics, which is an optical-design house for high-performance waveguides.

The higher the index, the wider the FoV

The high refractive index of the Schott wafers allow a field of view (FoV) of up to 65° aimed at providing a more-immersive user experience than devices with a narrower field of view.

"With the demonstration of a resin matching the optical properties of the latest Schott RealView generation and meeting the requirements of EVG's mass-manufacturing NIL process, the missing link in the fabrication system of next-level field-of-view waveguides is now accessible," notes Rüdiger Sprengard, head of augmented reality at Schott.

The fabrication of the demonstrator displayed at SPIE Photonics West was carried out at EVG's NIL Photonics Competence Center using its wafer processing equipment that included EVG's recently introduced Hercules NIL 300 mm modular and integrated UV-NIL system with SmartNIL technology, which can replicate structures on substrates up to 300 mm in diameter.

Schott notes that it offers a range of glass wafers with refractive indices from 1.5 to 1.9 at wafer diameters of 100, 150, 200, and 300 mm.

Source: https://www.evgroup.com/company/news/detail/schott-inkron-evg-and-waveoptics-global-ar-leaders-team-up-to-enable-next-gen-waveguides-at-photonics-west-1580308811/

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.