SiGe alloys usable in silicon photonics emit light via direct bandgap

Researchers around the globe have been looking for a way to make lasers with silicon (Si) or germanium (Ge), in particular for use as a light source for Si photonic chips. A team from the Technical University of Eindhoven (TU/e; Netherlands) and the Technical University of Munich (TUM; Germany) has now succeeded in developing light-emitting Si-Ge alloys. As a result, the development of a Si laser capable of integration into today's chips is within reach for the first time.1

The crucial step in the development of the Ge-Si alloys capable of emitting light was the ability to produce Ge and alloys from Ge and Si with a hexagonal crystal lattice. “This material has a direct band gap, and can therefore emit light itself,” says Jonathan Finley, Professor of Semiconductor Quantum Nanosystems at TUM.

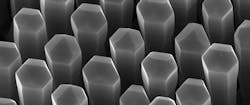

Erik Bakkers and his team at TU Eindhoven first produced hexagonal Si back in 2015. They started by growing a hexagonal crystal structure with nanowires made of another material. This served as a template for a Ge-Si shell on which the underlying material imposed its hexagonal crystal structure.

Perfecting the production process

Initially, however, these structures could not be stimulated to emit light. Through the exchange of ideas with colleagues at the Walter Schottky Institute at the Technical University of Munich, who analyzed the optical characteristics with each successive generation, the production process was finally optimized to a grade of perfection where the nanowires were indeed capable of emitting light.

“In the meantime, we have achieved properties almost comparable to indium phosphide or gallium arsenide,” says Bakkers. As a result, it appears to be just a matter of time before a laser made from Ge-Si alloys and capable of integration into conventional production processes is developed.

“If we can implement on-chip and interchip electronic communications by optical means, speeds can be increased by a factor of up to 1000,” says Jonathan Finley. “In addition, the direct combination of optics and electronics could drastically reduce the cost of chips for laser-based radar in self-driving cars, chemical sensors for medical diagnostics, and air and food quality measurements.”

Source: https://www.tum.de/nc/en/about-tum/news/press-releases/details/35970/

REFERENCE:

1. E. M. T. Fadaly et al., Nature, 580, pages 205–209, April 2020; doi: 10.1038/s41586-020-2150-y.

Got optics- and photonics-related news to share with us? Contact John Wallace, Senior Editor, Laser Focus World

Get more like this delivered right to your inbox

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.